Dies Lubrication

For sure, among the secrets of an expert, to get forged parts at high productivity and without defects, the ability to manage the dies lubrication is one of the most important.

Actually, it is necessary to know how to have a “right lubrication” of the dies.

Clearly, “right lubrication” does not mean “a lot”, but on the contrary it means:

- Well distributed on every point of the die;

- Specifically differentiated between lower die figure, upper die figure, punches heads and their sliding channels…

Punches with spiral grooves to ease the lubrication distribution around the surface

“Right” means first of all to choose the most suitable materials, for the metal that we will forge, and dose or, if required, mix them in the best ratio to obtain the two basic effects of this operation:

- To allow the easy sliding of the punches on the die and of the billet material in the die figures;

- Reduce the temperature of the die components, to increase their working life duration.

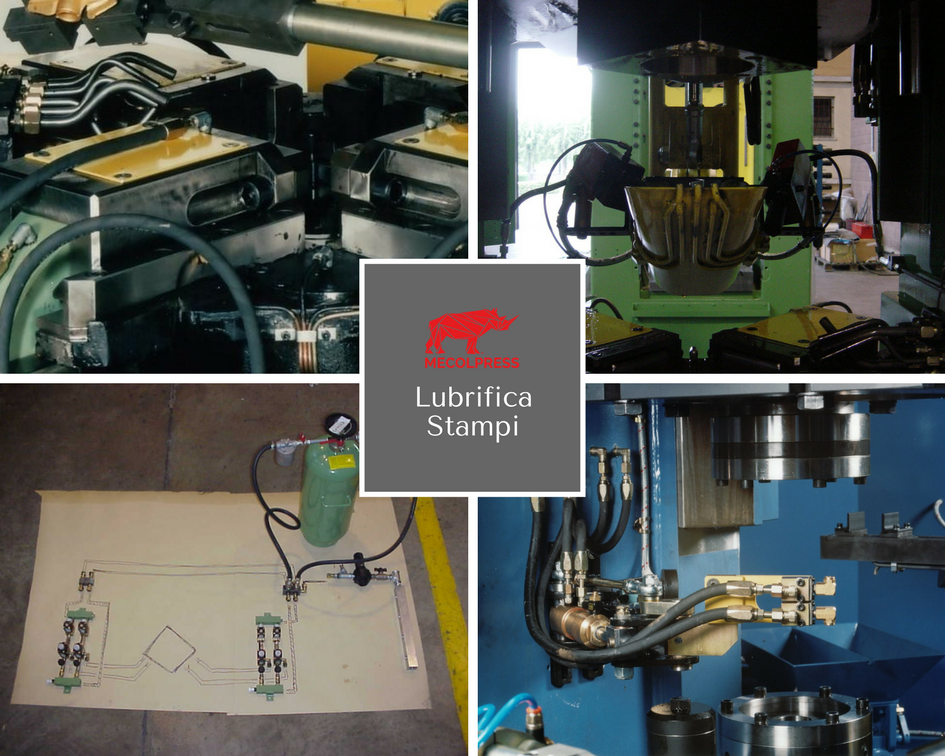

The dies lubrication mix, typically oil and graphite, is dosed by valves that are very distant from the spraying point, therefore a variation in the quantity settings becomes effective only after many cycles, all those necessary for the new quantity of fluid to cover the whole way from valve to spraying point.

These, the spraying points, are copper pipes that, from a distribution block mounted on the subpress, are directioned and bent to target the specific points: the die figures, the punches etc.

In this way, every time the die is to be changed, it becomes necessary:

- To redirect the copper pipes, having every time to find the perfect position;

- To dedicate a lot of time to the set up operation.

And how is it made in the new generation of presses? Read more