The new hydraulic press with heating-cutting bars online

Presentation of new hydraulic press ME100 / 4L30 with with very high productivity,

Heated+Cutting Bar on-line

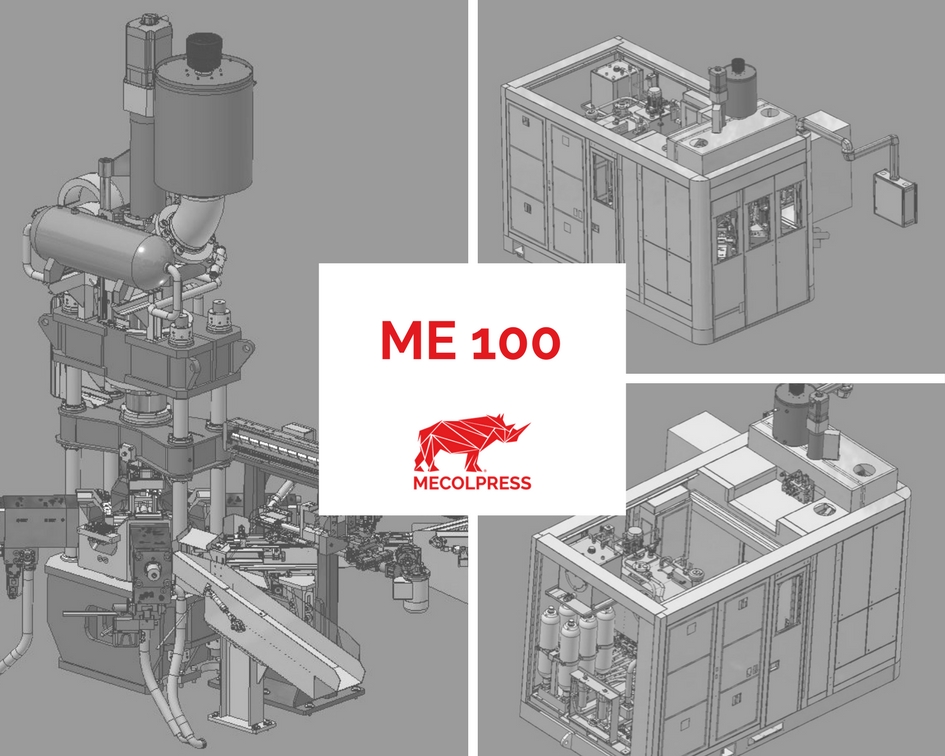

The new compact hydraulic press ME100-4L-30 dedicated to the forging of complex shapes with low weight, with extremely high productivity.

The new machine is an evolution of the well-known and appreciated Mecolpress ME hydraulic machines, installed and working all around the world, from Japan, through Korea and China, up to Germany and Italy.

Features:

- Multiples coring possibility, single or double shape forging (parallel or head-to-head), in vertical, horizontal and at any angle.

- Advanced motion solutions to grant highest speed and the most precise control.

- Designed with focus on fast set up and easy access, maintenance and cleaning.

The brass bars heating+shearing furnace GBH5000 is what the market is since long waiting for:

a bar heating furnace, that at the same time can shear into billets, built as a stand-alone unit.

Advantages:

– independent from the press, as furnaces have always been: can be connected to new or existing presses, hydraulic, mechanic or screw presses, and loading automation, of whatever brand;

– allow the user the best flexibility in the production organisation and company development;

– for all lengths of bars up to 5 meters;

– no problems with small diameters;

– no damaging of the brass grain structure because of long-time high-temperature heating.

We will preview the machine at EMO 2017, follow the event.