>>>>

The line is composed by:

Automatic sawing machine, with bar bundle loader

A motorized conveyor to deliver the cut billets directly to the furnace

(for those parts that will be chrome plated) or to the graphitizing machine.

The graphitizing machine, with powder automatic dosing:

the graphitizing of the billets offers various advantages, like a reduced gas consumption and longer die life.

The push type gas furnace

The forging press SEO/3

with loading and unloading automation, and with GE subpress with 5 punches (4 horizontal + 1 vertical).

The trimming press S/1

for removing the flash from those parts that are not forged flash free, complete with a box tipper.

The sandblasting machine

with box-tipper loading device and vibrating conveyor for the unloading.

The complete forging line is the answer for customers that need to forge:

- ball valves up to 1”,

- related caps, and various nut and plugs completely flash free,

- undersink valves,

- wash machine valves,

- gas valves,

- Tees and elbow fittings and many more.

Many parts can be forged two pieces per stroke (also in vertical), and the productivity goes from 900 up to 1.800 pieces per hour.

Being completely automatic, once the set-up is completed, the operator just have to put the brass bar bundle on the sawing machine, and collect the forged parts from the press.

Since the graphitizing machine and the furnace have an hopper to store the billets, the operator can start the sawing machine in advance, when he is finishing the set-up of the press.

In this way, with a modular concept, the set-up time can be cut and a down time of the sawing machine or the graphitizing machine does not mean a stop for the forging press.

Why choose a line like this?

- Mecolpress designed this line together with the customer, choosing each single element to find the perfect fit to technical and economic requirements.

- Great care has been put in developing the best layout, to save space and grant easy access to all machines, both for the regular operation as well as for service need.

- This is a turn-key project, in which Mecolpress is the single contact for the customer for all his questions, for the set-up, the installation, the training and the warranty of all equipment.

Straight from the bar… to the finished forged part!

The reasons why you should appreciate (and prefer…) the modularity

In the planning and realization of different forging lines there is a common denominator, and it is the main machine, the heart of the entire project: the press.

Even if it concerns aluminum or brass forging, the press manufacturer must have a broad view, that can contemplate the entire process, from raw material bars to the finished part. An optimum press has to be born “conceived” in such a way that allows it to be able to work in synergy with the other components of the line, in order to guarantee to the user the maximum efficiency and minimum wastefulness.

The most important manufacturer’s feature that every customer who buys machineries looks for is reliability: the certainty of providing themselves with a product that “performs”, that gives satisfactions and no worries. Obviously, the moment of the initial choice of the machine is crucial, and it is determined by understanding the variety and variability of customer’s necessities over time and by the manufacturer’s competence satisfying them.

And then, steps that cannot be considered “less” crucial will arrive: installation and activation of the machine, for example. These are moments you will spend calmly, if you have someone by your side that assumes wholly the responsibility to have delivered the machine, to have verified that it works during the entire working life of the machine, as expected by the costumer, since the manufacturer is present from the start up.

Putting effort into guaranteeing all this means to be completely “master” of their own technology and of all the components that compose the line, thought as many different “segments” of a whole. We all know that presses for working and going into production need accessories, like sawing machine, furnace, deburring machine…

The skilled press manufacturer knows how to give the right relevance to these segments, by addressing the customer to the most appropriate choice (both for technical characteristics and budget characteristics) for him, by offering the most correct solutions, even if these are supplied by the manufacturer himself or if these are reachable directly from the customer by other specialized manufacturers.

The habit to think and to study every single “segment” of the forging line so that it contributes to the best, in its peculiarity, to the line efficiency has a name: modularity. The numerous satisfaction “stories” of the “Top performer” customers indicate the modularity as the most efficient way to go.

How many elements, realistically, is the press connected to? The list is long:

- traditional gas heating furnaces,

- Induction heating furnaces,

- graphitizing machines,

- arms or external Robots and of third party for loading/unloading of the machine,

- trimming presses,

- sandblasting machines,…

In the face of a so articulate system, the experience shows us that the “compactness” is not enough.

There is no doubt that setting up a line according to the modularity criterion will request:

- Time and patience;

- active consultation of the manufacturer;

- the need of being informed and updated on the market proposals

- Once the choices are made and components are purchased, arranging the suitable places to place them.

But let’s resume exactly from here. The possibility to “save” spaces, indeed one of the main subjects of the offers of compact lines manufacturers, seems not to be a small advantage.

However, combining many specific machines in just a “compact” solution for the above-mentioned advantage to save space risks to compromise the production results. Unfortunately, the matter of fact is that a break of just one component is enough to stop the entire “compact line” activity. So, the risk is: I have optimized the space, but the banal breakdown, for example of a blade of the shearing machine could cause the stop of the total production. At that point, having saved space will not be a great consolation, unfortunately.

The style of modularity belongs traditionally to manufacturers who knows thoroughly the problems and matters that who forges must face every day. Who has this kind of knowledge also knows well that the fact of being able to intervene in a focused and independent way on every components of the line has no price.

The modular concept, that as we have already seen, provides to have the press in line but separated from the furnace and even not in line with the other machines (as, for example, the sawing-machine or the graphitizing machine, that working separately, can create “buffer” stock of semifinished parts along the line), it allows:

▲ The biggest flexibility: the customer can choose the components he prefers (gas or induction furnace, sawing machine or seaming machine…), changing them in the future to answer to new needs, and to adapt the line layout to a company that develops.

▲ The press, since it is independent from furnaces and sawing machine, can be used in the future for forging other types of brass alloy, or copper or aluminum.

If sawing-machine, furnaces and press are “melt” in just one machine, this is not possible.

▲ Every machine can give its best (a good sawing machine can cut more billets/hour than a press can print) and does not have to adapt to the speed of the slowest machine.

▲ The line will be able to be easily adapted to non cylindrical classic billets, but also, for example pre-bent, disc shaped, billets with special contour.

▲ The best efficiency: each machine is independent, the press can forge when the sawing-machine needs a blades replacement: on the contrary, when the die on the press is replaced, the sawing machine can continue to prepare billets.

A solid knowledge of the machineries is the fundamental base that allows the manufacturer to design and propose the best technical and economical solution for the customer’s needs. Since the manufacturer is specialized in the production of presses and since he is not obliged to provide with the press its own sawing/shearing machine and furnaces and not those of anybody else, will be able to suggest to the customer the best solutions to the specified needs.

The range of the proposal is very wide, and it is possible to range from new lines (in which each component is totally new and realized by the best specific manufacturer) to lines in which one or more parts are overhauled. But is welcomed also the costumer that, choosen the press manufacturer for trust and reliability reasons, then refers to him to have consultation and indications for the other components to add so to have a complete line, “ad hoc” both for the technical production requirements and for the “wallet” ones.

Regardless of your belonging sector: thermal-hydraulic, gas, automotive, railway, biomedical, special screws, clothing components, the modularity confirms always to be the winner, exactly for the flexibility that guarantees to the forging line and for maintaining its efficiency.

The most commonly installed equipment on the eccentric mechanical presses is the EG (Extruder Group).

Used in the production of the cored parts, it is available in more than a size. Each of these sizes, related to its dimension, allow to forge parts of gradually bigger dimensions, until the 2” valves.

Thanks to the production of cored parts through the EG (Extruder Group), then it is possible to achieve a considerable reduction of waste material during the production steps.

Indeed through this tool, it is possible to save till 40% of material compared to the full forging modalities, without coring!

How does the Extruder Group work?

When the Extruder Group is into function, the Extruder Group, through the vertical movement set by the descent of the slide, creates the horizontal movement of 4 carriages. The function of the so operated carriage is to create some cavities (holes) in the parts, guaranteeing a significant reduction of the waste material during the production stages.

Through the movement, the EG distributes the energy generated from the press to the 4 carriages. This energy transfer is connected to the part that is going to be forged and during the deformation the material will need always more power, in particular the thicknesses of the diaphragms between the holes can require efforts higher than 450 tons.

Extruder Group usage

The Extruder Group is an equipment that becomes operative at medium temperatures (350-400 °C) and it deforms the material in a considerably wide temperature range: indeed, it goes from 400°C of aluminum to 1100°C of copper.

Indeed, the Extruder Group allows the forging simultaneously of more parts (till 4 parts), at the same time of a variable cycle from 6 to 45 hits pro minute. Therefore, during the production process, a press in continuous cycle can produce till 180 parts pro minutes.

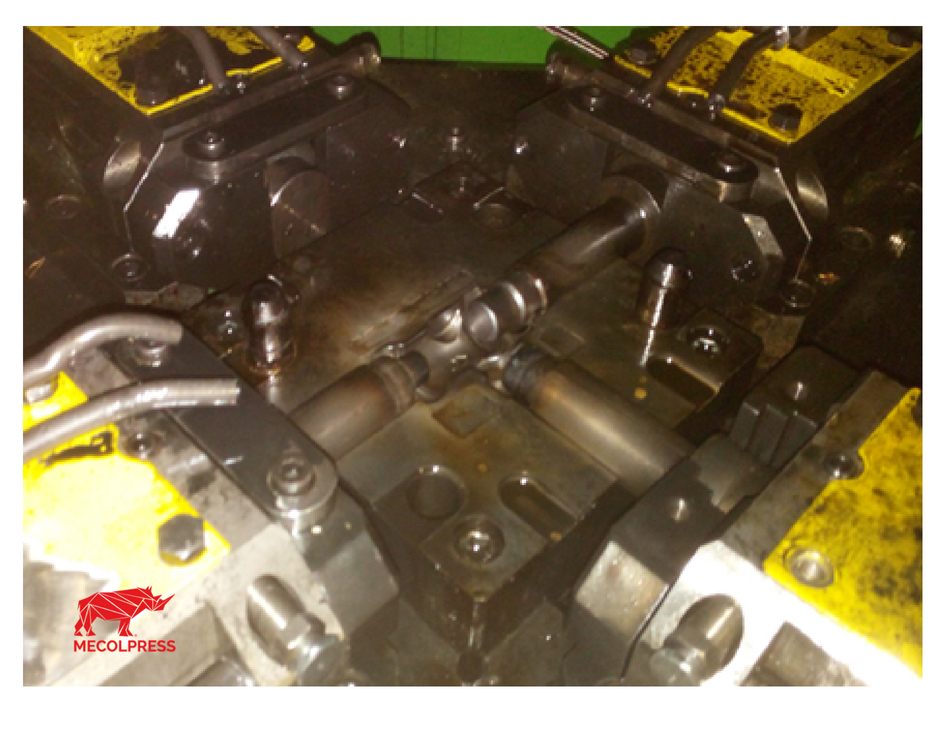

In the picture you can see an extruder group during the production. It is possible to identify 4 carriages (yellow), and, in the middle, the die where the material to forge will be deformed (in this case, brass).

Ectruder Group GE

In this video you can see the GE in operation:

PRIVACY POLICY

As required under Italian Legislative Decree No. 196/2003 and EU Regulation No. 679/2016 (GDPR) and with reference to the personal data concerning you that will be processed by us, please be informed of the following:

1. PURPOSES OF PROCESSING

Mecolpress S.p.A., in its capacity as the data controller, will process the personal data of the customer for the following purposes:

- a) deliberating on whether to conclude a contract with the customer (financial standing of the customer, potential consequences of the contractual relationship in terms of reputation, anti-bribery and money-laundering compliance);

- b) concluding the contracts with the customer, as well as managing and performing the contracts entered into with the customer;

- c) complying with the provisions of the Italian Civil Code, as well as with any other tax-related or accounting obligations; complying with contractual obligations; providing technical support and assistance with regard to the products and services purchased by you, including after sale and after the expiry of the related warranty, where expressly agreed; managing the contractual relationship from an administrative viewpoint;

- d) with reference to marketing and references, information on future commercial initiatives, product and/or service innovations, offers.

2. LEGAL GROUNDS OF PROCESSING

The personal data of the customer are processed on the basis of consent expressed upon signing of this Privacy Policy.

Be informed that in the absence of consent or in the event of withdrawal of the same, we may still process your personal data on the strength of the following legal grounds.

- a) processing is necessary for the performance of the contract to which you are a party or in order to take steps at your request prior to entering into a contract;

- b) processing is necessary for compliance with a legal obligation to which Mecolpress S.p.A is subject.

- c) processing is necessary to protect the interests of a natural person;

- d) processing is necessary for the performance of a task carried out in the public interest or in the exercise of official authority vested in Mecolpress S.p.A.;

- e) processing is necessary for the purposes of the legitimate interests pursued by Mecolpress S.p.A.; in particular, legitimate interests may include:

- the interest to enter into, manage and perform the contracts under section 1, item b) above;

- the interest to protect the company’s interests arising – directly or indirectly – out of the above contracts;

- the interest to protect the company’s security and assets;

provided that the interests or the fundamental rights and freedoms of the data subject are not overriding.

3. PROVISION OF PERSONAL DATA

Without prejudice to the right of the data subject to make an independent choice, provision of personal data to be obtained directly may be:

- a) obligatorily required in order to comply with national laws and regulations, EU legislation or provisions issued by the competent authorities or by supervisory and monitoring bodies;

- b) strictly necessary for the conclusion of new contracts between Mecolpress S.p.A. and the customer or the management and performance of existing contracts.

Objection by the data subject to the processing of personal data and/or refusal by the same to provide personal data may lead to the impossibility for or refusal by us, in whole or in part, to enter into any new contracts with the data subject or to perform the contracts that are already in place, to fulfil obligations imposed by national laws and regulations, EU legislation or provisions issued by the competent authorities or by supervisory and monitoring bodies

4. DATA COLLECTED FROM THIRD PARTIES

Be informed that the personal data which are subject to processing, in particular for the purposes under section 1, item a) above, may be obtained from third parties, rather than directly from the data subject, by accessing specific databases or using dedicated enquiry services.

5. METHODS OF PROCESSING

Personal data may be processed through analogic or electronic or simply automated means, using the methods and procedures that are strictly necessary to pursue the purposes above.

Mecolpress S.p.A. may process the data directly through persons that belong to its organisation or through external entities. Such persons and entities will process the data:

- a) in accordance with the instructions provided by the data controller, acting in their capacity as persons authorised to process the data or processors, exclusively for the specific purposes set out in this Privacy Policy.

- b) independently, as independent controllers.

6. DISCLOSURE AND DISSEMINATION OF PERSONAL DATA

For the exclusive purposes under section 1 above, personal data may be disclosed to:

- a) employees or contractors of Mecolpress S.p.A. who have been authorised by the company to process the data;

- b) lending institutions, providers of document registration, packaging, transport and sorting services, works contractors and service providers, notaries, lawyers, assessors, debt collection firms and consultants, independent auditing firms;

- c) entities to which the personal data must be disclosed to comply with collective agreements (e.g.: trade unions) or specific legal obligations (e.g.: public security bodies and other public authorities).

Personal data will not be disseminated under any circumstances.

7. RIGHTS OF THE DATA SUBJECT

The legislation on the protection of personal data (articles 7-10 of Italian Legislative Decree No. 196/2003 and articles 12-22 of EU Regulation 679/2016) grants the data subject the right to be informed of the processing of personal data, as well as the right to access the data at any time and to request their updating, completion and rectification. Where the relevant conditions apply, the data subject shall also have the right to request erasure of personal data or restriction of processing, the right to data portability, the right to object to processing, as well as the right not to be subject to decisions based solely on automated processing.

When processing of personal data is based on consent by the data subject, the latter shall have the right to withdraw consent.

To exercise your rights or to obtain more detailed information on the persons or entities to whom your personal data are disclosed or who may come to learn your data in their capacity as processors or as persons authorised to process the data, you may contact the data protection officer of Mecolpress S.p.A. at the following address: Via Don Maestrini, 51 – 25020 Flero (BS), Italy, or at the following email address: gdpr@mecolpress.com

Should you believe that your rights have been affected, you may lodge a complaint with the Personal Data Protection Authority.

8. PERIOD FOR WHICH THE PERSONAL DATA WILL BE STORED

The personal data will be stored for the time necessary to achieve the purposes under section 1 above, and, once the above purposes have been achieved, until expiration of the rights to which you and Mecolpress S.p.A. are entitled in consequence of the legal and de facto relationships occurred between the parties and in connection – directly or indirectly – with the above purposes (10 years).

As regards marketing purposes, the data will be stored for 5 years.

9. PROCESSING OF THIRD-PARTY DATA

The customer is informed that should the customer choose to involve third parties (e.g.: representatives, employees, contractors) in the performance of the contracts entered into with Mecolpress S.p.A., the personal data of any such third parties may be processed by Mecolpress S.p.A., in its capacity as data controller, for the purposes under section 1 above and, in particular, for the management of the contracts with the contact persons and representatives of the customer.

Said processing shall be carried out for the same purposes and in the same manner and the data shall be stored for the same period as previously described in this Privacy Policy; with regard to said processing, the data subjects shall have the same rights as identified under section 8 above.

The customer undertakes to inform any data subjects involved by the customer with regard to the above processing, including by giving them this Privacy Policy and getting them to sign it for acceptance.

As required under Italian Legislative Decree No. 196/2003 and EU Regulation No. 679/2016 (GDPR) and with reference to the personal data concerning you that will be processed by us, MECOLPRESS SPA – Via Don Maestrini, 51 – 25020 Flero (BS) Italia informs you that:

1. PURPOSES OF PROCESSING

The data you enter in the contact form, may be processed to contact you and for marketing purposes: for example, sending – with automated e-mail contact and promotional and commercial communications related to services / products offered by the Company or notification of business events, as well as carrying out market studies and statistical analysis.

2. LEGAL GROUNDS OF PROCESSING

The personal data of the customer are processed on the basis of consent expressed upon signing of this Privacy Policy.

Be informed that in the absence of consent or in the event of withdrawal of the same, we may still process your personal data on the strength of the following legal grounds.

- a) processing is necessary for the performance of the contract to which you are a party or in order to take steps at your request prior to entering into a contract;

- b) processing is necessary for compliance with a legal obligation to which Mecolpress S.p.A is subject.

- c) processing is necessary to protect the interests of a natural person;

- d) processing is necessary for the performance of a task carried out in the public interest or in the exercise of official authority vested in Mecolpress S.p.A.;

- e) processing is necessary for the purposes of the legitimate interests pursued by Mecolpress S.p.A.; in particular, legitimate interests may include:

- the interest to enter into, manage and perform the contracts under section 1, above;

- the interest to protect the company’s interests arising – directly or indirectly – out of the above contracts;

- the interest to protect the company’s security and assets;

provided that the interests or the fundamental rights and freedoms of the data subject are not overriding.

3. PROVISION OF PERSONAL DATA

Without prejudice to the right of the data subject to make an independent choice, provision of personal data to be obtained directly may be:

- a) obligatorily required in order to comply with national laws and regulations, EU legislation or provisions issued by the competent authorities or by supervisory and monitoring bodies;

- b) strictly necessary for the conclusion of new contracts between Mecolpress S.p.A. and the customer or the management and performance of existing contracts.

Objection by the data subject to the processing of personal data and/or refusal by the same to provide personal data may lead to the impossibility for or refusal by us, in whole or in part, to enter into any new contracts with the data subject or to perform the contracts that are already in place, to fulfil obligations imposed by national laws and regulations, EU legislation or provisions issued by the competent authorities or by supervisory and monitoring bodies

4. DATA COLLECTED FROM THIRD PARTIES

Be informed that the personal data which are subject to processing, in particular for the purposes under section 1, above, may be obtained from third parties, rather than directly from the data subject, by accessing specific databases or using dedicated enquiry services.

5. METHODS OF PROCESSING

Personal data may be processed through analogic or electronic or simply automated means, using the methods and procedures that are strictly necessary to pursue the purposes above.

Mecolpress S.p.A. may process the data directly through persons that belong to its organisation or through external entities. Such persons and entities will process the data:

- a) in accordance with the instructions provided by the data controller, acting in their capacity as persons authorised to process the data or processors, exclusively for the specific purposes set out in this Privacy Policy.

- b) independently, as independent controllers.

6. DISCLOSURE AND DISSEMINATION OF PERSONAL DATA

Within the limits relevant to the purposes of processing indicated, your data may be disclosed to partners, consulting firms, private companies, appointed by the Data Controller. Your data will not be disseminated in any way. The Data Processors and Data Processors are promptly identified in the Privacy Policy, which is updated on a regular basis.

Any data dissemination operation is excluded.

7. RIGHTS OF THE DATA SUBJECT

The legislation on the protection of personal data (articles 7-10 of Italian Legislative Decree No. 196/2003 and articles 12-22 of EU Regulation 679/2016) grants the data subject the right to be informed of the processing of personal data, as well as the right to access the data at any time and to request their updating, completion and rectification. Where the relevant conditions apply, the data subject shall also have the right to request erasure of personal data or restriction of processing, the right to data portability, the right to object to processing, as well as the right not to be subject to decisions based solely on automated processing.

When processing of personal data is based on consent by the data subject, the latter shall have the right to withdraw consent.

To exercise your rights or to obtain more detailed information on the persons or entities to whom your personal data are disclosed or who may come to learn your data in their capacity as processors or as persons authorised to process the data, you may contact the data protection officer of Mecolpress S.p.A. at the following address: Via Don Maestrini, 51 – 25020 Flero (BS), Italy, or at the following email address: gdpr@mecolpress.com

Should you believe that your rights have been affected, you may lodge a complaint with the Personal Data Protection Authority.

8. PERIOD FOR WHICH THE PERSONAL DATA WILL BE STORED

The data collected will be kept for a period of time not exceeding the achievement of the purposes for which they are processed (“conservation limitation principle”, art.5, GDPR) or on the basis of the deadlines established by law. The verification of the obsolescence of the data stored in relation to the purposes for which they were collected is carried out periodically.

9. PROCESSING OF THIRD-PARTY DATA

The customer is informed that should the customer choose to involve third parties (e.g.: representatives, employees, contractors) in the performance of the contracts entered into with Mecolpress S.p.A., the personal data of any such third parties may be processed by Mecolpress S.p.A., in its capacity as data controller, for the purposes under section 1 above and, in particular, for the management of the contracts with the contact persons and representatives of the customer.

Said processing shall be carried out for the same purposes and in the same manner and the data shall be stored for the same period as previously described in this Privacy Policy; with regard to said processing, the data subjects shall have the same rights as identified under section 8 above.

The customer undertakes to inform any data subjects involved by the customer with regard to the above processing, including by giving them this Privacy Policy.

At Mecolpress, customer care is a fact. These are the words of the person in charge of after sales service Francesco Minoni that, in this interview, has told us regarding a service projected to the future with a rich archive of historical information, recorded and documented.

“The after sales service is a pride for Mecolpress because is a service born with the company and together with it has grown and developed – says Francesco Minoni, department coordinator from 2012. “Mecolpress is today a completely digitalized organization. It is, by now, an ordinary routine for us to assist the client in real time”.

But to the promptness we can add values as competence and a great availability of material. The first one is guaranteed by Francesco’s employment record, whose career started in Mecolpress through the roles of electrician and then as an installer, with a strong knowledge of the machines the factory produces. Instead, regarding the availability of the materials, the efficient response of Mecolpress lies in the extension of the areas addressed to the stock of pieces which can be required by clients (two dedicated warehouses) and by investments in favor of the stock-keeping.

The physical consistency of available material is matched by a database in which has been transferred, thanks to a specific recovery operation of the history of the company, all the information regarding the installation and the maintenance of each sold machine that today “we can really recall with a simple click”, says Francesco.

At this point we have no alternative but to imagine to be a stalled client. In discomfort, the good news is to know that we can speak to an expert, efficient and, above all, able to act rapidly contact person. “The waiting time, of course, depends on the type of the breakdown. However, we almost always have at disposal, if not the finished piece, the rough piece from which we can generate it. In case of problems with the gearwheel unit, the heart of the machine, if we are not able to supply the finished piece, we have rough and semifinished pieces already in stock”.

Service is a strong point of the company but also an advantage in the relationship with the clients: from the historical ones who know well the wide range of spare parts they can count on, but also for the new clients or for the ones who contact Mecolpress for consultation and replacement of machines of different brands. “For example, during these days, – Francesco adds – we are managing to supply a spare part of a Russian screw press 45 years old”.

Issues are quite a lot, of different types even depending on the material the client is using: “one of our clients, for example, produces professional bows in aluminum. It means 700 mm of aluminum to forge with a huge machine and that is feasible: with a force of 1600 tons the part comes finished as well! But the problem is to, beyond the lubrication, custom-made it. Once it is finished, the aluminum piece has to satisfy aesthetic concerns. It’s completely different for steel, where you have to struggle with the mechanical stress and with function-related issues, with machines used to their limits”.

From the moment in which a fault arises it is communicated, what happens in Mecolpress? Thanks to the documentation scanned and to the material immediately accessible, we can trace in real time the general framework of each press and detect of each accessory. Understanding the nature of the problem is a task of the service department, which finds the right ways to solve it, using the phone, e-mail and live chat, in order to ensure efficiency and speed.

“The service we offer – Mr. Minoni concludes – is very precious because we live in a transaction period, where machines are always developing in the technological way, while the internal resources of the factories don’t always appear aligned to the trends. From one side the average operator is typically low receptive regarding the use of new devices, even because sometimes temporary staff lacks basic communication skills. We believe that training is the idea to follow, and someone does this, as one of our client who after purchasing a press attended at Mecolpress an intensive and very articulated training.

Do you know Mecolpress after sales service?

Contact us to find out more! We will be happy to answer to any of your doubts.

The most curious thing to know regarding the graphite – one of the allotropy forms of carbon – is that it can be considered from the chemical point of view a diamond twin. But it is completely different for the physical features: first of all, it’s black! And, in addition, it has its own, very precious, application in the protection covering of metallic areas exposed to corrosion. Keep reading if you want to discover more about graphite and about graphitizing!

Graphite, a precious mineral for industry

To the touch it is unctuous and slippery, graphite has a metallic shining and a density between 2,09 and 2,2. Extremely soft (with a variable hardness between 1 and 2) it’s very easy to scratch. It solidifies in the hexagonal system, not in the shape of completely developed crystals, but in the shape of scales or irregular masses. It is the only not metal that is a good electricity conductor, on the contrary it conducts heat in a bad way.

It exists in nature as a mineral that includes impurities, it is amply supplied all over the world; important deposits are located in England, Siberia, Madagascar, Mexico, Sri Lanka, Canada and in many American places.

It is also artificially produced, warming up for 11-13 weeks at a temperature of 950 degrees Celsius a blend of petrol and carbon derivatives and then transferring the product of the cooking in electric furnace, where for 4-5 weeks it remains at the temperature of 2.800 degrees Celsius. Most of the process of graphitization (that is a warming at the temperature of 2500-3000 degrees Celsius) it happens not only for the temperature but also for a refinement caused by a reduction of metals and vaporization of metal oxides present in carbon.

What is graphite for?

Graphite is used for electrodes in the electrochemical industry, for electrical furnace or crucibles addressed to very high temperature, in industrial paints.

Moreover, it is used as lubricant (sometimes mixed with grease, oils or water) in a semi-permanent treatment that is called graphitizing and it is used in order to protect the metallic surfaces.

The graphitizing process

Graphite is a lubricant element and it can be available as powder or as paste. It guarantees the homogeneity of the superficial color of the billet. In addition, it produces a positive effect on gas consumption for the heating of brass or aluminum billets because, by making them black, it facilitates the heat absorption.

As it is lubricant, regarding the mold it contrasts efficiently:

- Consumption

- Wearing out

Furthermore, it avoids that the billets stick one to another in the push-type gas furnace. It is a widely used process in Italy and less in other countries that, though, is not always recommended (for example in the case of products subjected to chrome plating).

For aluminum is interesting the treatment realized with not black graphite but of silver color. This coloring minimizes the visibility of possible dark spots on the pieces.

Graphitizing and working of metals

The graphitizing machines are essentially rotating drums, where the pieces of cut bar are inserted, to which some grams of graphite are added. During the necessary time of rolling, the graphite powder is homogeneously distributed on all the pieces, facilitating the next stage of the hot forging.

The goals of lubrication, during the working of metals are complexes. The reasons we interpose lubricating material between the basic material to be worked and the tools or die that produce the deformation can be summarized in:

- Friction reduction;

- Use reduction;

- Surface aspect;

- Temperature control;

- Form changing control;

- Distribution control of the stresses in the product.

Regarding the surface aspect, thanks to their properties to avoid the contact between metals, lubricants can prevent the developing of marked and poor-quality surfaces on the product. But simply producing a not damaged surface could be not enough because a bright, reflecting or matt aspect can be required. In that sense, the lubricant used makes a significant difference.

Graphite is confirmed the real classic lubricant in solid film. It sticks well to the metallic surfaces and, for that reason, it is usually used for the pre-treatment of the tools and dies, as an additive for other lubricant at room temperature and, in particular, as lubricant for high temperature operations. The disadvantage is that graphite is not easy to remove once the working is finalized.

For some types of processes and materials to be worked, the choice of each kind of lubricant it’s in many cases very easy, but the real choice of a specific lubricant – best composition and condition for the use – it is not. In the operative reality we have to take into consideration so many factors (the available equipment, the tonnage produced, the range of products to be manufactured with a certain equipment, pre -and -post working treatments) so that each lubrication problem can be treated in a specific way. So it is better to get to the final lubricant choice only after a careful evaluation of the application.

Would you like to protect the metallic surfaces? Entrust them to Mecolpress!

What are cookies

A “cookie” is a small text file created on the user’s computer when he accesses a particular site, with the purpose of storing and transporting information. Cookies are sent by a web server (which is the computer on which the visited website is running) to the user’s browser (Internet Explorer, Mozilla Firefox, Google Chrome, etc.) and stored on his computer; they are then sent back to the website at the time of subsequent visits. During navigation, the user may receive cookies from different sites on his terminal (so-called “third-party” cookies), set directly by the operators of said websites and used for the purposes and according to the procedures defined by them.

Types of cookies used by this site

Owner’s cookie

The site https://www.mecolpress.com uses only technical cookies, with respect to which, pursuant to art. 122 of the Privacy Code and the Provision of the Guarantor of 8 May 2014, no consent is required from the interested party. More precisely, the site uses: Technical cookies strictly necessary to allow browsing by the user, in the absence of which the website could not work properly; Functional technical cookies, which facilitate user navigation;

Third-party cookies

Google Analytics

The Site uses Google Analytics. It is a web analysis service provided by Google Inc. (“Google”) that uses cookies that are stored on the user’s computer to allow statistical analysis in aggregate form in order to use the website visited. The data generated by Google Analytics are stored by Google as indicated in the information available at the link: https://developers.google.com/analytics/devguides/collection/analyticsjs/cookie-usage.

To consult the privacy policy of the company Google Inc., owner of the independent processing of data relating to the Google Analytics service, please refer to the website: http://www.google.com/intl/en/analytics/privacyoverview.html

Buttons and widgets of social networks

Buttons and widgets of social networks Social buttons are those particular “buttons” on the site that depict icons of social networks and allow users who are browsing to interact with a “click” directly with social platforms. The site incorporates buttons and widgets of Facebook, Instagram and Linkedin, which involve the installation of cookies, also profiling, of said Social. No information is instead shared by the site where the button and widget is embedded. For more information, including on the deactivation of these cookies, we recommend that you consult the following links:

Facebook (Facebook Inc.): Policy Privacy: https://www.facebook.com/privacy/explanation –

Policy Cookie: https://www.facebook.com/policy/cookies/

Linkedin (LinkedIn Corporation): Policy Privacy: https://www.linkedin.com/legal/privacy-policy –

Policy Cookie: https://www.linkedin.com/legal/cookie-policy

Instagram (Instagram Inc.): Policy Privacy: https://help.instagram.com/155833707900388 –

Policy Cookie: https://help.instagram.com/1896641480634370

Salesmanago

The SALESmanago code assigns different types of cookies, which mainly have the purpose of:

– Monitor anonymous and B2B visits (these are cookies assigned to all users who visit the site and accept cookies)

– Monitor a contact -specific and identified-to track behavior and habits (these are cookies assigned to the contact in case the user performs certain actions, such as clicking on a link inserted in an email SALESmanago o compiling a form generated by the system or integrated via API) For more information on all the types of cookies assigned by the system and their functionality, you can consult the dedicated page.

Method of processing

The treatment is done with automated tools by the owner. No dissemination or communication is made.

Provision of data

Except for technical cookies that are strictly necessary for normal browsing, the interested party can avoid the installation of cookies through special functions available on his browser.

Disabling cookies

Without prejudice to the foregoing in relation to cookies strictly necessary for navigation, the user may delete the other cookies through the functionality provided for this purpose by the Owner through this information or directly through their browser. Each browser has different procedures for managing settings. The user can obtain specific instructions through the links below:

Microsoft Windows Explorer: http://windows.microsoft.com/it-it/windows/search#q=cookie

Google Chrome: https://support.google.com/chrome/bin/answer.py?hl=it&answer=95647&p=cpn_cookies

Mozilla Firefox: http://support.mozilla.org/it-IT/kb/Enabling%20and%20disabling%20cookies

Apple Safari: http://support.apple.com/kb/PH17191?viewlocale=it_IT&locale=it_IT

The deactivation of third-party cookies is also possible through the methods made available directly by the third-party company for this treatment, as indicated in the links in the paragraph “third-party cookies”.

User rights

The interested party can assert at any time, by contacting the data controller by sending an email to gdpr@mecolpress.com, the rights referred to in art. 7 of Legislative Decree 30 June 2003 no. 196, which is reported below.

Art. 7 D. Lgs. 196/2003

1. The user has the right to obtain confirmation of the existence or not of personal data concerning you, even if not yet registered, and their communication in intelligible form.

2. The user has the right to obtain the indication:

a. the origin of personal data;

b. of the purposes and methods of processing;

c. of the logic applied in case of treatment carried out with the aid of electronic instruments;d. of the identifying details of the owner, of the responsible and of the designated representative according to article 5, paragraph 2;

e. of the subjects or categories of subjects to whom the personal data may be communicated or who can learn about them as appointed representative in the territory of the State, managers or agents.

3. The user has the right to obtain:

a. updating, rectification or, when interested, integration of data;

b. the cancellation, transformation into anonymous form or blocking of data processed unlawfully, including data whose retention is unnecessary for the purposes for which the data were collected or subsequently processed;

c. the attestation that the operations referred to in letters a) and b) have been brought to the attention, also with regard to their content, of those to whom the data have been communicated or disseminated, except in the case in which this fulfillment proves impossible o involves a use of means manifestly disproportionate to the protected right.

4. The user has the right to object, in whole or in part:

a. for legitimate reasons, the processing of personal data concerning you, even if pertinent to the purpose of the collection;

b. to the processing of personal data concerning you for the purpose of sending advertising or direct sales material or for carrying out market research or commercial communication.