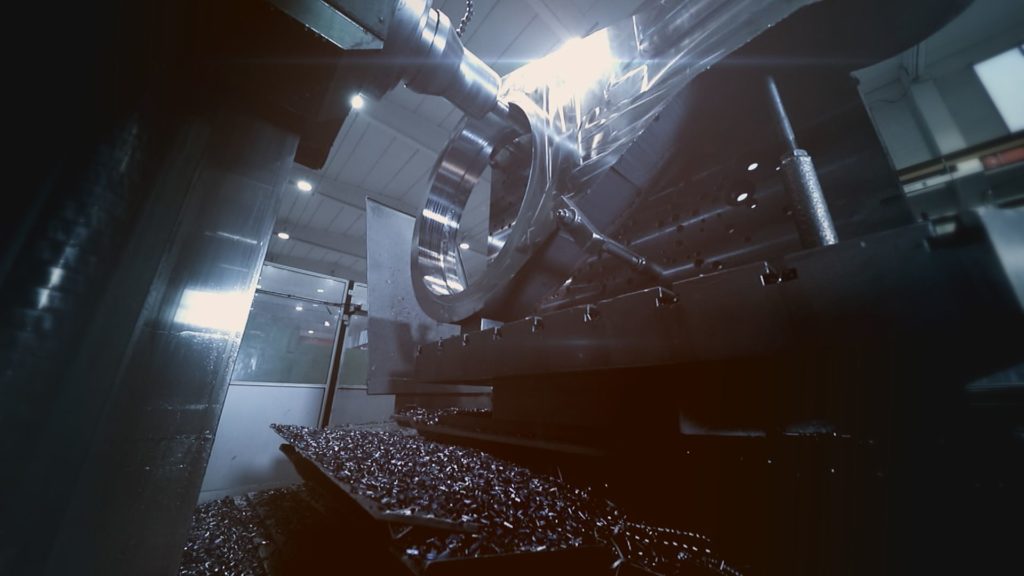

Hot forging and titanium machining

Titanium is a particular resistant material, often used for hot forging. Mecolpress proposes furnaces and both hydraulic and mechanical presses suitable for the forging of titanium alloys of parts destined to different application sectors.

Mecolpress offers to its customers a wide range of presses for titanium hot forging and our sales department is always ready to offer a customized advice to suggest the best machinery according to the used alloy to forge and to the type of geometry the customer wants to obtain.

Titanium features

Titanium is lighter and much more resistant than steel: for this reason, it is often used in the medical sector for the realization of particular prothesis.

Characteristic features of titanium are:

- low specific weight,

- hardness,

- biocompatibility,

- non-toxicity,

- low thermal conductivity,

In addition to be widely used in the medial sector, titanium, thanks to its features, is a metal extremely versatile that can be used in many other sectors, including automotive, aerospace, industrial sector of mechanics and applications in field of sport.

Titanium forging: Mecolpress machines

The temperature for titanium billets forging is about 950°C and the one of the die is about 250°C, instead. The hot forging of titanium parts is very well suited to obtain the desired parts, since by using the right equipment it is possible to avoid all the problems this material should present during the melting.

For this reason, our sales department is at disposal of our customers in order to advice for the choice of the most suitable hydraulic or mechanical press and to suggest the modes of operations. Mecolpress can carry out a simulation test at our factory, thanks to Deform software, and a real forging test so that to grant to our customers that the chosen machine can forge high quality parts.

For further information regarding press models suitable for titanium hot forging, please refer to our sales managers that will be glad to examine in depth the matter.

Metals hot forging process

Metals forging: hot or cold forging?

The forging by means of presses of metals commonly used for the industrial production, such as aluminum and brass, can happen in two ways.

- The first one is the cold coining, carried out, for example, on a piece that already has its own shape and that is forged through the press in such a way to calibrate it and to compact it. The cold coining is suitable, above all, for small size parts and for great production batches, such as screws. The most suitable machines for this type of process are our screw presses.

- The metals hot forging is different from the cold one because it allows to obtain high quality pieces by means of an important deformation of the starting material. With the deformation of brass, copper, aluminum by means of hot forging presses it is possible, indeed, to produce particular shapes, having very complicated structures as well. In order to achieve this forging, Mecolpress proposes, beyond the already mentioned screw presses, also the mechanical and hydraulic presses according to the different production necessities expressed by the customer.

Mechanical and hydraulic presses for the hot forging

The mechanical press can hot forge even complicated pieces. At the end of the process, the forged parts can often have some remaining flash that can be eliminated by means of a trimming machine, machinery that is part of the products range that we offer. The eccentric mechanical press with continuous cycle is recommended for the customers who have high production necessities, while the hydraulic press is more advisable for parts having very complicated shapes and that would require, otherwise, the usage of a lot of material. This type of press permits, indeed, a saving of the input material, so offering to the forger a good margin on the product cost. Moreover, by forging the parts by means of hydraulic hot forging presses, at the end of the productive cycle the parts range that can be produced without flash is much wider, thanks to a progressive and programmable application of the forces. Another characteristic of this type of presses is the flexibility, given by the wide number of available functions.

Hot forging line

For the metals forging a furnace that can be electric (induction) or gas furnace and a press are needed. This is the base productive line for the aluminum, brass, titanium and steel processing; line that can be upstream completed with a sawing machine that cuts the metal bar in billets and with a graphitizing machine, where the billets are treated with the graphite before these are inserted in the furnace, so that these absorb better the heat and that are kept lubricated. The graphitizing, that offers remarkable advantages from a productive point of view, such as a minor gas consumption in the furnace and a superior durability of the dies, is just fitting for some specific production typologies. It is not recommended, for example, for the production of parts that once forged, must be chrome plated or exposed to further particular treatments. Our sales department is at the disposal of our customers for suggesting the best forging line composition according to the product and to application field.

Hot forged metals

The customer’s choice for a specific press for his own productive cycle is based on the material typology used by the forger and on the shapes to achieve.

For the brass forging the hydraulic press is more fitting than the screw press, that is better for the forging of titanium and steel. The eccentric mechanical presses are used for all the metals, even for the copper hot forging. Our sales department is at disposal of our customers for offering the best technical solution for every specific productive situation.

For further information about hot forging machineries, please write us at sales@mecolpress.com