Discover Mecolpress

“𝗗𝗶𝘀𝗰𝗼𝘃𝗲𝗿 𝗠𝗲𝗰𝗼𝗹𝗽𝗿𝗲𝘀𝘀”:

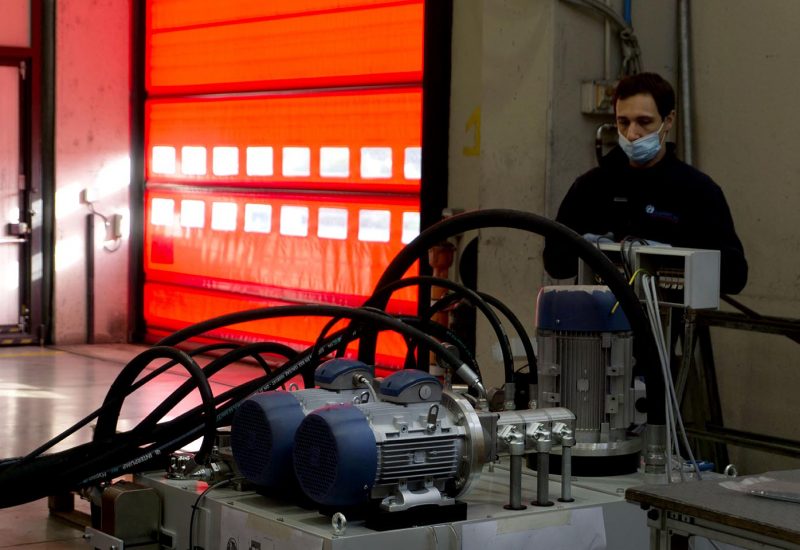

Discovering Mecolpress: a journey through backstage pictures.

With some pictures “caught here and there” and with some related comments we will try to let you know more about our Company.

We will drive you to the discovery of Mecolpress world, about our constant dedication to growth and innovation of hot forging technologies, and how we work hard to guarantee you the best reliability and Customer Care service of all over the world.

Our aim is to use a point of view that is not “stick” or simply related to the ordinary catalogue pictures; we will use the reportage style showing aspects that are usually hidden, but that, according to us, can reveal interesting and valuable peculiarities.

A path that tends to highlight, to reveal that behind the machines, technology and mechanism there are women, men that thanks to their ideas and passion constantly contribute to develop new solutions for the evolution of our products and services.

This is a way to show a “human” aspect of Industry, made not only of aseptic engineering but also of ability, expertise, experience of people who lives daily the company, the productive workshop and the administration/management offices.

Pictures revealing a soul made of personal skill, methods rich in creativity that can be found also in the details of the productive process.

It is also through these initiatives that companies can share aspects, information and pictures that tangibly contribute to the growth and strengthening of the relationship between companies.

BORN WITH HOT FORGING OF BRASS, ENLARGING TO ALUMINIUM AND STEEL: THE VISION OF MECOLPRESS

Read the Corriere della Sera special dedicated to the metallurgical industry. This article talks about the vision of Mecolpress as a supplier and manufacturer of hot forging machinery. Click here:

METALLURGICAL INDUSTRY THE EXCELLENCE OF MADE IN ITALY

BORN WITH HOT FORGING OF BRASS, ENLARGING TO ALUMINIUM AND STEEL: THE VISION OF MECOLPRESS

… as undisputed leader in the production of hot forging presses for brass components, in recent years we added the focus on technologies for steel and aluminum applications.

MECOLPRESS: THIRD GENERATION TO GROW AND IMPROVE EVEN MORE

Read the special “Giornale di Brescia” dedicated to Mecolpress, click here:

Mecolpress Special Edition June 4th

The technology and the strategies to win the challenge

Click on image for the English version of the article:

The change is a constant in our lives and for Mecolpress, for more than 50 years, it is seen as an opportunity.

That’s how that the best projects and products are born and developed.

Shape the Future!

#MECOLPRESSCHRISTMAS2020

Usually in Mecolpress, to celebrate Christmas, we express each other good wishes with two special events: a dine-out evening that allows us to share special moments, stories and anecdotes, and a toast in production on the last day of work accompanied by the speech of our president.

This year obviously it will not be possible to do any of this, so what?!?!

What can we say about 2020 coming to an end?

Certainly the year we are leaving behind is a year that we will remember because of Covid that has not spared any country in the world.

If we are to talk only about the Mecolpress reality, we can now consider ourselves lucky in terms of health. And also from a work point of view the year is ending without major deviations from the previous year even if we had foreseen a very aggressive budget that aimed to different results, we can say that the current situation caused by Covid has not put us in particular difficulties as may have happened for other types of companies or other production sectors.

This year it was not possible to carry out some technical interventions in some countries, all the trade fairs to which we were registered could not take place, and we had to postpone visits to our mainly foreign customers.

But we’ve all learned to use more digital tools, which allow us to meet remotely.

We have even tested entire forging lines remotely, and more and more customers have chosen to use our calipso software for forging control.

But above all we had the opportunity to verify with pleasure and satisfaction, that our customers from all over the world (some even newly acquired!) have renewed their confidence despite the physical distance.

What interesting news we have implemented internally in 2020?

Speaking instead of the Mecolpress reality inside we can say that we have finished most of the works planned in the new Shed 5, specifically the most interesting thing we implemented was the purchase and starting up of a powerful induction oven. This oven is for our exclusive internal use and allows us to perform forging tests not only for brass and aluminum pieces, but also for steel pieces. Steel in fact needs higher temperatures than other materials. Thanks to the work that our technical engineer specialized in hot steel forging is doing, we are investing a lot in the production of machines for this material.

We realize more and more that for the customer to have the proof, to see the piece to must be forged, concretely made by a machine that we always have available to carry out forging tests, is very important!

Often customers come to us who have to make even complex pieces, with many doubts and perplexities. It is of great satisfaction for us to show them how the Mecolpress press that we recommend to them, after study by our technical office that also uses a forging simulation, can make their piece with higher quality requirements. And it’s that added quid that has often allowed us to make a difference.

What we expect in 2021?

The spread of Covid-19 obviously weighs on any forecast or programming. But we hope to reschedule many businesses that have been postponed in 2020. We are currently investigating global markets to assess how much customers will be able to invest in the coming months.

However, we are full of preparation and positivity, our sales force is working to propose solutions suitable for needs that may be changing.

And above all we are on the piece!

Mecolpress Best Wishes

Since it is not possible to exchange greetings as usual, we just have to do them online, but with our hearts. We sincerely hope you can spend a serene Festivities, this is the wish we address as well to our employees and their families, our customers and collaborators.

Because Mecolpress is made by all of you, of people who work every day, collaborate, give us confidence and make Mecolpress not only a company but a large family.

In this regard we ask you to share with us selfies, a wish, a phrase, or a toast … to share the wishes with us, DISTANT BUT UNITED:

Post your message on the social networks and mention @mecolpress

Insert the hashtag #MecolpressChristmas2020 #WeAreOnThePiece

Our social channels:

Mecolpress, 50 years in the hot forging sector

This year Mecolpress has reached the goal of its first half century of activity by presenting a new continuous and discontinuous cycle press at EMO exhibition in Hannover, held last September.

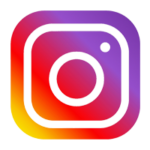

In the present of Mecolpress there is also an investment in the world of electric scooters.

The video story by the management of Mecolpress:

Established in 1969 by Giulio Molinari, Giulio Barbisoni and Pietro Caggioli, MECOLPRESS was founded as a manufacturing company of mechanical presses for brass components hot forging. A few years later, in 1973, the company acquired its current production site in Flero, in via Don Maestrini, initially extended over an area of 2,000 square meters, and then it expanded increasingly reaching 6,000 square meters in 1993. Today Mecolpress has acquired a second industrial area next to the first one where the construction of a warehouse is coming to an end, reaching a total area of 30,000 square meters.

In addition to the industrial area expansion, over the years Mecolpress has aimed higher and higher thanks to the acquisition of two important brands of the screw presses production: the Italian company, Dellavia (1993) and the Swiss company, Osterwalder (1998). The company has always distinguished itself as an avant-garde reality in the forging sector: remarkable are the production of the first continuous cycle mechanical press in 1983, the production of the first continuous cycle electronic press in 1993, the design and construction of the hydraulic press for hot forging of brass components without flash in 2008 and the presentation on the market of the screw press with direct drive motor in 2013.

In September of this year, in occasion of EMO exhibition in Hannover, Mecolpress officially presented the new series of continuous and discontinuous cycle eccentric presses, the HEAVY series.

This new machine has an innovative and modern structure, more robust, and designed to simplify the control and maintenance for the operator. The automation and the dies lubrication of the machine was completely renewed, thanks to the addition of a bearing, that allows, among other things, for vibrations reducing and it is provided with a new intelligent software for the production process analysis and for predictive maintenance.

On 31st August, Mecolpress celebrated its first 50 years of activity by opening its doors to the families of the employees who work at the Flero site every day. In this first half century of activity, there have also been moments of sacrifices and difficulties, but the tenacity and determination of its founders allowed Mecolpress to emerge very quickly in a particular market such as the forging one.

The second generation played an important role in the history of the Rhinoceros, as well, in particular, during the economic crisis of 2008, when the company could make courageous decisions, expanding its business, pushing on the accelerator of innovation and research, trying to renew itself and pushing beyond the borders drawn by parents. Now the company has reached the maturity of an important reality that operates all over the world, where the glorious history of its beginnings coexists with the desire to get involved that has especially characterized with research and innovation the last years.

With the background generated by this mix of values, now also the third generation appears in the management panorama.

Watch the video of our Anniversary Party:

Mecolpress, a new adventure

In 2018 Mecolpress acquired the majority of the shares of ME Group, manufacturing company of electric scooters with an unique design, becoming the reference partner alongside the founders. The entry of Mecolpress formally coincided with the passage of ME Group from Innovative Start Up to Innovative SME. This formal transition was in fact also substantial, thanks to the contribution of Mecolpress from a financial point of view and above all from the point of view of know-how and industrial approach to the organisation of the company. ME is the first scooter in the world with a patented frame made of SMC (Sheet Moulding Compound), a compound of thermosetting resins with excellent performances in terms of strength and resistance in relation to its weight. This electric scooter can be recharged like a mobile phone: it can be fully recharged in 3-6 hours (depending on the battery charger used), connecting the scooter directly to a domestic outlet in the garage or office or extracting the battery.

The ME Start Edition version (sold out) was followed by the range available from the 2019 season: 2.5 kW moped model, 45 km/h top speed (limited by law) and 80 km range and 6 kW model with a speed of 80 km/h. Touch display, USB socket and a range of accessories in continuous evolution complete the equipment of ME.

Company numbers:

Mecolpress has grown over the years both in terms of volume of the industrial area and in terms of numbers. Starting from the employment situation: in 1985 Mecolpress had 29 employees, in 2018 it practically doubled its staff to 55 employees. Turnover and production are also growing: in 1985 the company turnover was just over 2.7 million euros. By 1995, turnover rose to 7.5 million euros and then the last available turnover (2018) exceeded 11.3 million euros.

Over the years production has also gone hand in hand with turnover increase. Today Mecolpress has 559 customers in 59 countries worldwide. All over the world there are 1126 Mecolpress machines, including screw presses (101), mechanical presses (806), hydraulic presses (40) and trimming machines (179). Most of them (763) are located in Europe, but the Flero-based company has also exported in Africa (62), Americas (103) and Asia (198).

In addition, Mecolpress is particularly active in after-sales service. The heart and pride of Mecolpress is its large spare parts warehouse, which is able to supply accessories or spare parts for machines produced fifty years ago. For this reason, in addition to the sale of machinery, there is a wide activity related to the service and supply of accessories (such as tools, arms, spare parts, etc..) in the order of more than 1,000 units, bringing the total production of machinery and spare parts to 2183 pieces.

The technology of the shape

The importance of the shape in the industrial applications

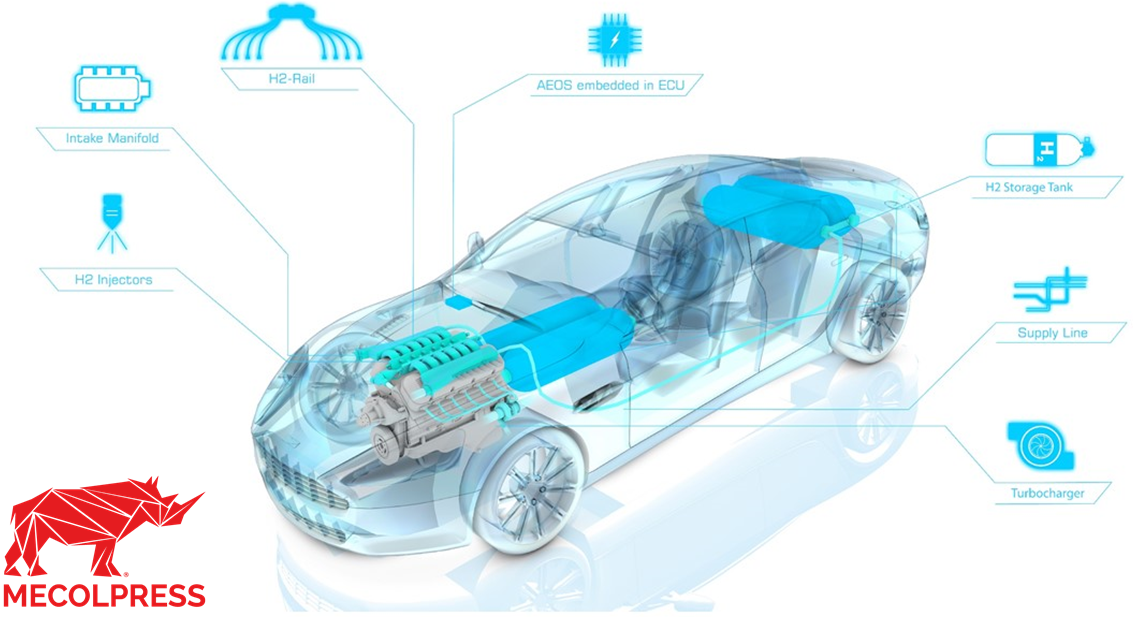

The hydraulic presses manufactured by Mecolpress are able to produce extremely high precision parts, that fully respect the characteristics of the shape originally thought by the designers. This allows to create products of very high complexity like the hydrogen-powered car, that is based on components with the lowest tolerances and on shapes that match each other with highest precision.

Auto ad idrogeno secondo l’interpretazione di Aston Martin (www.astonmartin.com/media)

The hot forging of materials allows, more than any other technology, to obtain perfect shapes and with high resistance, that can be employed in excellence productions.

Mecolpress is a leader in the manufacturing of mechanical and hydraulic presses as well as in the consulting services to use the hot forging technologies for the precision of the shape.

What would be of the technological progress without the shape technologies?

The history of the mankind shows that the research of always better performing and innovative solutions has lead to an accurate care of the details in the production of a perfect shape, in the mechanic industry as well as in the hydraulic, medical technic and building sector ones.

The Shape Forming Technology is also the title of this permanent blog, that Mecolpress issues and updates with the purpose to highlight the need of research and investments for the well-being of the people.

The mechanic of Mecolpress is dedicated to the shape forming technology to provide its customers with the abilities of producing in an always more precise and efficient way.

Follow us on internet facebook LinkedIn