The dies lubrication determines your forging success!

Knowing to take advantage of the correct dies lubrication is crucial in a hot forging system of brass, steel, aluminum, titanium or copper parts.

We have already highlighted many times in our previous articles how the lubrication can make the difference and solve many of the common problems that the forgers observe during the production of their forged parts. Our research of the perfect lubrication has evolved, becoming more and more precise and customizable, exactly like we are constantly required by the market.

A correct lubrication doesn’t mean that it must be of large quantity, but that it must be correctly dosed and the most appropriate lubricants must be chosen according to the metal types and required part to be forged.

The dies lubrication system of hydraulic presses of ME series and of eccentric press at continuous cycle of HEAVY series

With the hydraulic presses of ME series and the mechanical eccentric at continuous cycle presses of HEAVY series we have revolutionized the dies lubrication system:

- We drag the outgoing oil+graphite mixture on the lubrication point.

- We let the lubrication liquid and the compressed air flow in two concentric tubes of the control valves of the single points up to the usage point.

- For each of the points the pilot is independent and therefore for each of them we give the possibility to the user to choose from the operator panel how, when and how often to intervene.

But we were not satisfied yet!

Which are the requests the forgers most frequently address to us?

We have verified that some of the questions you ask our service department are regarding the lubrication system:

“My die has broken, what can I do to guarantee it a long-lasting life?”

“The dies lubrication system I am using is not satisfying.”

“Is it possible to reduce the waste of lubricants, in view of an even more ecological choice?”

“How can I obtain a successful forging system?”

Our Research and Development team has therefore perfected and developed a new lubrication system.

What’s new in the lubrication system of the HEAVY series

Heavy series is our new proposal of a mechanical eccentric at continuous cycle press. It is a very revolutionary machine, the result of 50 years of experience in the hot forging presses production, and of the continuous search for innovation and technology perfection.

As a result, we have completely reviewed even the automation and the dies lubrication.

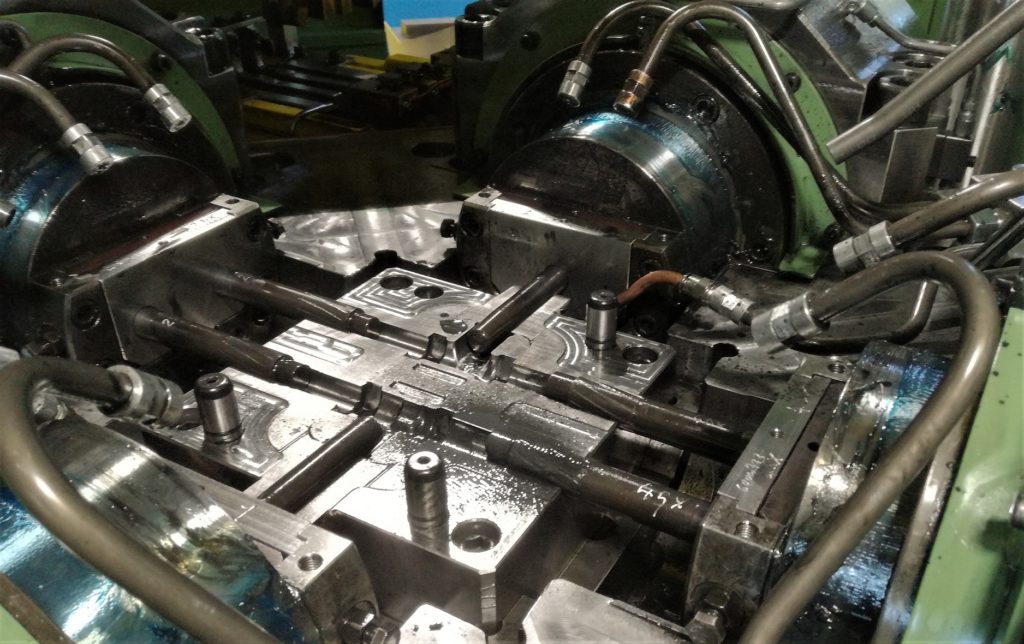

First of all, the dies lubrication system allows for each single point the independent and programmable management.

It is possible to start the lubrication cycle in different ways: during the ascent or descent of the ram, during the loading or unloading cycle, with appropriate delay and duration times.

Each point can be used for the nebulization of the lubricant or for the cooling and cleaning of the dies.

The system can be implemented with 2 or more high capacity air blowing points.

It is possible to program the schedules: the pumping circuit, the automatic mixer and the heating resistance placed in the tank allow to prepare the liquid and the entire circuit for the starting time at optimal conditions.

The nebulization of the lubricant, thanks to the particular pipe system, is obtained only in proximity of the usage area: in this way the dosage, repeatability and the sensibility to the dosage variation are guaranteed.

40 lubrication/cooling points are foreseen, of which 16 are placed in the lower dies-holder and 16 in the upper dies-holder. The disposition of the lubrication/cooling points throughout the dies allows to reach efficaciously the critical points to be lubricated/cooled, in addition to drastically reduce the times of production change.

Reactive, smart system for creating your recipes

The responsiveness to the settings variations is immediate, unlike the traditional system that requires several minutes of production before it stabilizes.

In addition to this, we can have a strong blowing without the help of compressors (that are contributing to increase the consumptions and the general maintenances of the plant).

A smart software system helps moreover the operator to adapt automatically the dosage of the lubricant in the startup phase of the production, till to reach the correct forging conditions.

Our system can be adapted even to the use of lubricant/water-base release agent, e.g. used in the aluminum sector, that are different from the classic graphitized oil.

All the parameters, activation of the used points, start modalities, timers and counters, once they have been optimized, are saved in the recipe devoted to the type of the part to be produced, in order that for the following batches of the same article there is a fast production start without useless waste of time.

STEEL HOT FORGING: THE WORD TO OUR EXPERT

We interviewed Luca Di Donato, Mecolpress specialist for steel hot forging.

Steel is a far different material from brass, for this reason Mecolpress has decided to increase its team with a devoted figure, to whom we have addressed some questions.

Let's talk about steel hot forging

What is your role in Mecolpress?

The role I currently play in the company context is project engineer manager specialized in steel hot forging and non-ferrous alloys (except brass).

Specifically, I mainly deal with the identification and definition of the hot plastic deformation process that is technically and economically most suitable for the production of semi-finished steel components but also aluminium and special nickel and Titanium alloys.

What kind of experience do you have in steel hot forging sector?

The gained background in the specific sector derives from many years of work experience acquired in the company field, initially as a designer and then as technical and operational director of companies located in Italy and abroad.

Which application sectors do usually use steel hot forging presses?

Presses for steel hot forging are widely used in many application sectors such as automotive, aeronautics, agriculture, construction, chemical, petrochemical and industrial sector in general.

Which type of machine is most suitable for steel forging? (mechanical presses, hydraulic presses, screw presses?)

From a metallurgical point of view, steel can be forged using every type of press, since the types of steel in general are little affected by the presses deformation speed as some aluminium alloys and the super alloys of Titanium and Nickel are affected.

Therefore, there are other parameters that influence the choice, in fact the geometry, the geometric and dimensional tolerances can certainly guide the choice on a mechanical press rather than on a screw press, but also on a hydraulic press.

Compared to brass, which are the distinctive traits of steel?

From the process point of view and therefore from the point of view of the relative presses, the first aspect that is typical for steel is certainly the forging temperature which is around 1200 ° C.

The other equally important feature is the steel deformability which is far more difficult than the one of the brass. The resistance to hot plastic deformation of steel forces the adoption of simpler geometries, the adoption of presses with increased capacity in terms of forces, moreover, pre-forming processes are often used.

According to your experience, which are the recurring critical issues that you could observe in the forging of this material?

As previously highlighted, steel is forged at high temperature, therefore possible overheating can be created in areas that are particularly subject to deformation, the involved forces are important and as a result the energy and disposition can approach the limit and cause no geometric conformity on the piece.

In the end, steel cannot be easily deformed and therefore it requires a specific study to understand which preforming processes are better to adopt in order to avoid cracks / folds of material.

Always according to your experience, when we want to choose the most suitable machine, what should we absolutely consider?

Obviously the geometry of the forged product to be obtained, together with the imposed geometric and dimensional tolerances, strongly influences the choice of the best process, first of all the type of press but also all the machines necessary to compose the line, from the cutting, heating, and preforming process up to the possible calibration of hot / cold forging.

Mecolpress, through the specific skills acquired in fifty years of working history and thanks to its professionalism, is able to support the customer from the very first stages of defining the most suitable geometry for the choice of the forging up to the realization of the line, also fully automated, turnkey.

What do you think that can really make the difference in a “guessed” press?

The heart of the production line in its entirety is the PRESS which has been designed to respect specific characteristics, as a result “guessing” the type of press is absolutely important, but it is equally essential to consider who designed and built it, in this regard the presses produced by Mecolpress are considered to be among the best on the market, both in terms of technological content and in terms of rigidity and reliability.

If you want further information regarding the topic “Steel hot forging”, we invite you to consult the U.NI.S.A. Italian National Union of Steel Forgers, of which we are aggregate members.

Training courses for hot forging

Starting from an inner necessity, Mecolpress has extended the training courses specific for hot forging machineries as a high-quality service against payment that can be offered to its customer companies.

Thanks to the course, it is possible to optimize the production and to improve machines maintenance.

The training value according to Mecolpress

Training is very important, especially in an even more complex productive context and in an even more competitive market. That’s why Mecolpress has felt the need to avail itself of the experience of a hot forging specialist to organize an inner training course of high level.

Understanding the world our customers operate in and learning the art of forging in the best way has always been our priority: therefore, we addressed to Riccardo Segreto that in this interview shared with us very useful suggestions and advanced technical information.

Una volta conclusa questa esperienza molto positiva all’interno della nostra azienda abbiamo quindi deciso di offrire questo servizio di alta formazione anche ai nostri clienti.

Advantages of training courses against payment

Training courses represents a very important instrument for the companies that deal with hot forging, because they offer to people who operate with mechanical and hydraulic presses very concrete and deepened indications regarding how to use them in the best way and to optimize the production.

Today it is not easy to find forging specialists that are available to teach trade secrets. Riccardo Segreto is an independent and very skilled figure, available to share with the companies useful suggestions in order not to wear the press or the die and to improve therefore the productive capacity.

Therefore, a highly qualified staff will be able to carry out some maintenance operations in complete autonomy on machineries for hot forging without the need of Mecolpress customer care service against payment. A correct use of the machine brings therefore to lesser damages and a reduction of machine stops that have a big effect on the production and then on the costs to support.

Our training courses against payment are custom-made developed according to customer’s needs and aimed to the types of presses present in the factory of the company that asked for training. Moreover, they provide an in-depth analysis of the parts to be forged and indications on how to forge them in the best way.

Thanks to our specialist, for example, it is possible to learn how to carry out in the best way the die lubrication and therefore how to prevent its wear and how to adjust the machine stroke. Working correctly with the press has as a result a considerable decrease of costs for our customer companies and that’s why we are firmly convinced that our training courses can represent an added value.

According to companies necessities, the courses can be held at our or customer premises and these have a duration of one or two days, according to the specific program.

Should you need further information regarding training courses, you just have to contact our sales department, sending an e-mail to sales@mecolpress.com.

Courses can be requested both by Mecolpress customer and companies dealing with hot forging that have the necessity to examine in depth some themes.

Hot forging and titanium machining

Titanium is a particular resistant material, often used for hot forging. Mecolpress proposes furnaces and both hydraulic and mechanical presses suitable for the forging of titanium alloys of parts destined to different application sectors.

Mecolpress offers to its customers a wide range of presses for titanium hot forging and our sales department is always ready to offer a customized advice to suggest the best machinery according to the used alloy to forge and to the type of geometry the customer wants to obtain.

Titanium features

Titanium is lighter and much more resistant than steel: for this reason, it is often used in the medical sector for the realization of particular prothesis.

Characteristic features of titanium are:

- low specific weight,

- hardness,

- biocompatibility,

- non-toxicity,

- low thermal conductivity,

In addition to be widely used in the medial sector, titanium, thanks to its features, is a metal extremely versatile that can be used in many other sectors, including automotive, aerospace, industrial sector of mechanics and applications in field of sport.

Titanium forging: Mecolpress machines

The temperature for titanium billets forging is about 950°C and the one of the die is about 250°C, instead. The hot forging of titanium parts is very well suited to obtain the desired parts, since by using the right equipment it is possible to avoid all the problems this material should present during the melting.

For this reason, our sales department is at disposal of our customers in order to advice for the choice of the most suitable hydraulic or mechanical press and to suggest the modes of operations. Mecolpress can carry out a simulation test at our factory, thanks to Deform software, and a real forging test so that to grant to our customers that the chosen machine can forge high quality parts.

For further information regarding press models suitable for titanium hot forging, please refer to our sales managers that will be glad to examine in depth the matter.

Aluminum hot forging: Mecolpress presses

Aluminum is a material that is often used for the hot forging of parts used in the automotive and electric sector. Mecolpress proposes specially-made presses for the production of high-quality parts.

One of the materials, often used by the forgers, is aluminum and Mecolpress proposes different presses suitable for this type of production.

Aluminum features

Aluminum is different from the other metals because of its lightness and for its good electrical characteristics. For this reason, it can replace, according to the application, steel that is heavier, and copper that is more expensive.

Forgers often use aluminum to produce parts for the automotive sector or for cycle and motorcycle: some examples are pedals and shafts, but also valves in the fuel supply columns.

Also in the fluid regulation sector, aluminum can be adopted in various sectors of application and regulators for gas pressure are produced. Other pieces are produced through aluminum hot forging and are destined to the electric sector.

Other products, realized with aluminum, are, for example, bows for arrows shooting.

The presses for aluminum hot forging work at a temperature of about 420°C-480°C, while the die temperature is around 300°C.

Mecolpress press for aluminum

L’alluminio ha una velocità di scorrimento più bassa rispetto all’ottone e bisogna prestare particolare attenzione alla temperatura utilizzata per lo stampaggio.

Aluminum has a lower flow speed than brass one and it is important to pay particular attention to the temperature used for forging. Mecolpress sales department offers to its customers a consultation service for suggesting the most suitable press to the production of aluminum pieces.

Our production range consists, indeed, of different mechanical and hydraulic presses and according to the used alloy and to the type of part to realize we can propose the machinery that satisfy the customer’ s needs.

Moreover, at our factory it is possible to realize a forging test for being able to verify the quality of the hot forged parts produced by our presses.

For further information please contact directly our sales managers.

Copper hot forging: Mecolpress presses

Mecolpress proposes a wide variety of mechanical and hydraulic presses for copper hot forging. Thanks to Mecolpress technology it is possible to obtain geometrical shapes, even the most complex ones, and to check all the process steps.

Mecolpress boasts a very long experience in the hot forging presses field and proposes to its customers a wide variety of presses with which it is possible to realize different pieces with simple and complex geometrical shapes. One of the most commonly used material by our customers for the hot forging is copper.

Copper features

This material is known for its conductivity features and it is especially indicated for the forging of parts used in the electric sector such as for example parts for switches, for connectors, battery clips, plates for heating dissipation of electrical parts.

The billets forging temperatures for copper are around 800°C, while the die temperatures are about 300°C.

Presses for copper hot forging: the Mecolpress solutions

The copper alloys are certainly expensive and for this reason it is necessary to optimize the productivity of the used press. Our sales department, according to the alloy used by the customer companies and to the geometrical shapes intended to obtain, is available to suggest which are the most recommended presses for copper hot forging.

Moreover, our customers, in case of needs, can commission us also the die to associate to the requested press.

Strength of Mecolpress is to be able to offer to its customers a forging test in very short time so that to verify with which forces it is necessary to operate to make the best use of the press.

To learn more about our range of presses for copper hot forging you can contact our sales department.

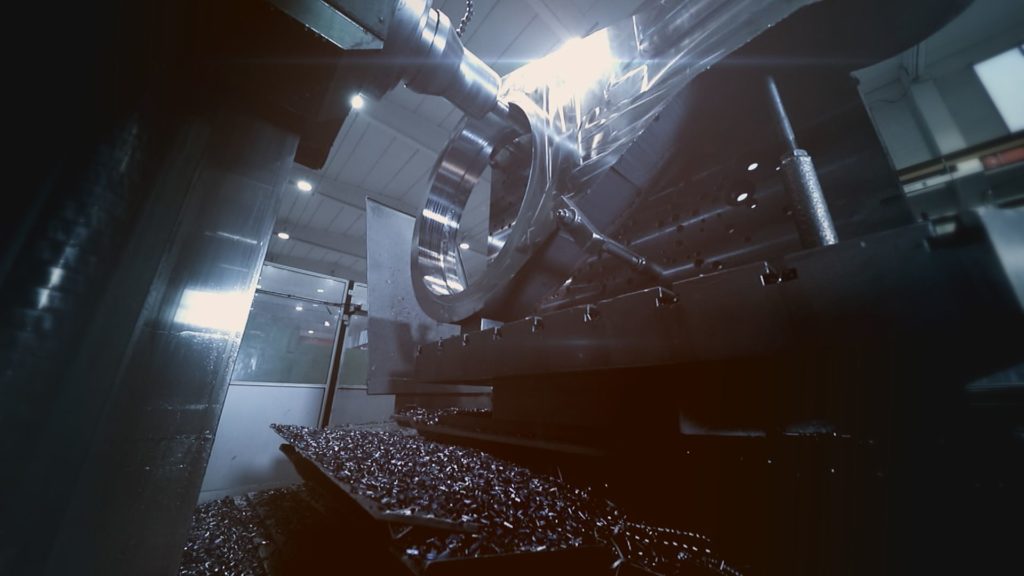

Steel hot forging: Mecolpress solutions

Mecolpress boasts a very long experience as producer of mechanical and hydraulic presses for the realization of hot forged steel parts. For a complete and detailed overview of our presses, please contact our sales department.

For the hot forging of steel parts, it is possible to use mechanical or hydraulic presses according to the geometrical complexity of the part to be forged and to the features of the specific alloy used for the forging.

Steel features

Steel is well-known for being a material having a considerable mechanical resistance and this characteristic makes it a material suitable for innumerable application sectors, including construction industry, automotive and railway sector.

Through the mechanical and hydraulic Mecolpress presses, it is possible to realize different types of parts, including for example screws and valves.

Steel hot forging presses

Mecolpress proposes to its customer companies different presses both mechanical and hydraulic for steel hot forging.

During the forging process of this material it is necessary to pay attention to the used energies and temperatures. Regarding the forging temperature of the billets, at presence of steel alloys, this goes approximately from 1.000°C to 1.200°C. The dies temperature is about 300°C, instead.

Moreover, during the steel hot forging process it is necessary to use the right lubricants in order not to wear the die and to optimize the production.

During the hot pressing of steel, the right lubricants must also be used in order to facilitate the flow of the material and the detachment of the same from the die. Mecolpress equips its presses with automatic lubrication systems with fixed or mobile points according to the specific application and in order to optimize the production process.

Our sales department remains at customer’s disposal to suggest the most suitable press to the production specific needs and, in addition, in the after-sale step it is possible to take advantage of a customized training course against payment, in order to learn all the tricks to make the best use of the bought press according to the production type.

The production cycle can be carried out completely automatically or manually according to the customer’s specific requests.

All the screw presses are customizable according to customer needs.

For further information you can contact our sales managers.

Hot forging of the brass: advantages of this material

The brass and its characteristics

The brass is an alloy composed of lead, copper, zinc and other metals, whose percentage can vary. The main component of this alloy is the copper that has a percentage between 55% and 62%. This high content of copper makes the brass a good electricity conductor and a material of easy mechanical machining because it does not wear out the cutting tools quickly as it instead happens for iron or steel.

Other typical features of the brass are:

- Recycling ease: brass is often remelt and reused to produce new parts.

- Resistance to a wide temperature range: during the hot forging process the brass is able to support, without creating particular critical issues, a moderate temperature range, this simplifies considerably the work, allowing a major tolerance in the usage of machineries.

- Lacking oxidation: During the heating phase inside the die, this metal is not subject to considerable oxidation.

- High corrosion resistance: the brass is a nonferrous alloy and therefore it does not get rusty.

Sectors of brass application

Thanks to its colour similiar to gold, the brass is used also for the realization of ornamental elements, home furnishing pieces such as for example handles and finishing for furniture, elements for clothing, including zippers and belt buckles.

Another sector of particular importance is composed by fluid control. This metal is particularly fitting for the production of valves, junction and fittings; since specific brass alloys with unimportant lead content were realized, the so produced pieces are therefore suitable to the contact with drinkable water. These special alloys are defined as Lead-free

In the end, as already underlined, the brass is a good electrical conductor and this characteristic makes him suitable for the realization of the electrical and electromechanical components, including switch parts, connections and terminals.

The hot forging process of the brass

The brass, that thanks to its particular plasticity permits to produce complicated geometrical shapes with simple processing, is hot forged as follows: when the press closes the dies with a single hit on the billet, it turns it into the part to be realized (in contrast to the steel that needs almost always a sequence of many hits). Inside the two halves of the die, that have the shape of the part to be realized, it is set down an enough quantity of metal in order to perfectly fulfill the entire cavity created by the two dies once they are overlapped and closed.

Presses for brass hot forging

For the hot forging of the brass it is possible to use continuous cycle presses or single cycle presses. The continuous cycle press is provided with a ram that moves continuously without stopping. The billets loading and the forged parts unloading is automatically adjusted by the electronic check. Instead, the single cycle press expects, at the dies reopening after a single hit, that the order for a new descent or closure of the dies must be sent by the user or by the PLC.

Mecolpress presses for the hot forging of the brass

For the hot forging of brass parts, Mecolpress proposes numerous mechanical and hydraulic presses with different characteristics according to the production typology that the customer wishes. Lately we have developed an innovative technology on our hydraulic presses for forging four parts with just a single hit that allows an important saving on the productive costs, come to discover how by reading the article!

Metals hot forging process

Metals forging: hot or cold forging?

The forging by means of presses of metals commonly used for the industrial production, such as aluminum and brass, can happen in two ways.

- The first one is the cold coining, carried out, for example, on a piece that already has its own shape and that is forged through the press in such a way to calibrate it and to compact it. The cold coining is suitable, above all, for small size parts and for great production batches, such as screws. The most suitable machines for this type of process are our screw presses.

- The metals hot forging is different from the cold one because it allows to obtain high quality pieces by means of an important deformation of the starting material. With the deformation of brass, copper, aluminum by means of hot forging presses it is possible, indeed, to produce particular shapes, having very complicated structures as well. In order to achieve this forging, Mecolpress proposes, beyond the already mentioned screw presses, also the mechanical and hydraulic presses according to the different production necessities expressed by the customer.

Mechanical and hydraulic presses for the hot forging

The mechanical press can hot forge even complicated pieces. At the end of the process, the forged parts can often have some remaining flash that can be eliminated by means of a trimming machine, machinery that is part of the products range that we offer. The eccentric mechanical press with continuous cycle is recommended for the customers who have high production necessities, while the hydraulic press is more advisable for parts having very complicated shapes and that would require, otherwise, the usage of a lot of material. This type of press permits, indeed, a saving of the input material, so offering to the forger a good margin on the product cost. Moreover, by forging the parts by means of hydraulic hot forging presses, at the end of the productive cycle the parts range that can be produced without flash is much wider, thanks to a progressive and programmable application of the forces. Another characteristic of this type of presses is the flexibility, given by the wide number of available functions.

Hot forging line

For the metals forging a furnace that can be electric (induction) or gas furnace and a press are needed. This is the base productive line for the aluminum, brass, titanium and steel processing; line that can be upstream completed with a sawing machine that cuts the metal bar in billets and with a graphitizing machine, where the billets are treated with the graphite before these are inserted in the furnace, so that these absorb better the heat and that are kept lubricated. The graphitizing, that offers remarkable advantages from a productive point of view, such as a minor gas consumption in the furnace and a superior durability of the dies, is just fitting for some specific production typologies. It is not recommended, for example, for the production of parts that once forged, must be chrome plated or exposed to further particular treatments. Our sales department is at the disposal of our customers for suggesting the best forging line composition according to the product and to application field.

Hot forged metals

The customer’s choice for a specific press for his own productive cycle is based on the material typology used by the forger and on the shapes to achieve.

For the brass forging the hydraulic press is more fitting than the screw press, that is better for the forging of titanium and steel. The eccentric mechanical presses are used for all the metals, even for the copper hot forging. Our sales department is at disposal of our customers for offering the best technical solution for every specific productive situation.

For further information about hot forging machineries, please write us at sales@mecolpress.com

Titanium and its features

In addition to be the fourth metal for its great abundance, titanium is the ninth element in order of industrial usage. It is preceded – obviously – by aluminum, iron and magnesium.

With atomic weight of 47,88 it is light and robust: its features combine high resistance, tenacity, rigidity, low density and a good resistance to corrosion.

Its low density (about 60% of iron density) can be strengthened through alloy elements and deformation processes. It is non-magnetic and it has a good characteristic of thermal exchange. Its coefficient of thermal dilation is a little bit lower than that of the steels and it is less than half of that of aluminum. Further useful trait is the high melting point of 3135° F (1725 ° C), about 400° C higher than that of the steel and about 2000 ° F higher than that of aluminum.

Titanium can be passivated, and it resists to the attacks of acids and base better than the stainless steel. The excellent resistance to corrosion and biocompatibility, combined with mechanical resistance, make it suitable for the chemical and petrochemical, sea environment and biomedical applications.

Regarding the electrical conductivity, the titanium’s one is 3,1% of the coppers one. So, titanium is not a good electrical conductor and it offers a high electrical resistance.

For a more complete vision, here you can find a table with the summarized titanium properties:

| Main titanium’s features | |

| Specific weight | 4.5 g/cm3 |

| Density | 4500 Kg/m3 |

| Melting temperature | 1680 °C |

| Thermical conductivity | 17 W/m°C |

| Linear thermal expansion coefficient (20-100 °C) | 8.9*10-6 /°C |

| Electrical conductivity | 3% IACS (copper 100%) |

From pure titanium to the alloys

The commercially pure titanium can be classified in 4 grades, that are essentially different for:

- resistance;

- usability.

In a nutshell, when the grade raises, the first increases and the second decreases.

The titanium alloys are divided into:

- Commercially pure titanium (CO): It’s the grouping that contains the highest proportion of titanium. Typical features are the high tendency to corrosion and mechanical features of medium-low value.

- α alloys: they present good weldability and maintenance of the mechanical characteristics also at high operating temperature, thanks to the generally high content of aluminum. The usage in components particularly solicited is impeded by the fact that these cannot be submitted to any thermal treatment.

- b alloys: they guarantee the best mechanical features. These have very restricted or null weldability, these are used in the constructions of bolts and springs and in strongly solicited parts.

- α+b alloys: in the group there are the most used alloys with elevated mechanical characteristics and largely used in the production of airplane’s components.

The titanium alloys, that are rather numerous, are classified in grades.

In the traditional manufacture, as also in the 3D printing, the following types of alloys are especially used:

- the Ti6Al4V (grade 5)

- the Ti6Al4V ELI (grade 23).

Among all titanium alloys, the grade 5 is the most used: engine parts, structural parts of airplane and automotive, fastening aerospace elements, and sport equipment of high quality.

The Ti 6Al4V ELI, or simply the grade 23, is the purer version of grade 5. Thanks to its biocompatibility, to its good resistance to stress and to the low module, it can be used in dental and health care sector.

Hot and cold forging of titanium

Hot or cold forged, titanium consents to create special processing of excellent quality.

In particular, the hot process guarantees significant advantages such as:

- Increase of resistance: the longitudinal continuity, even in the critical transit area between head and stem, is kept unchanged. The raw material can be shaped, by avoiding the cuts typical of the traditional turning works. The phenomenon of detachment between head and stem decreases and it is frequent in the wrought that are submitted to excessive stress. The absence of cut fibers increases the resistance.

- Saving of raw material; optimization of costs. Swarf are not created during the process: the raw material is not wasted and the price of the product decreases.

Advantages and disadvantages of titanium usage

Advantages:

- low specific weight

- Hardness

- Resistance to corrosion

- low thermal conductivity

- Radiolucency

- Biochemical inert

- Biotolerance

- Not toxicity

- Absence of taste

- Resistance to chewing

Disadvantages:

- Not enough precise melting

- Formation of a layer of oxide on the surfaces

- Detachments of ceramic covering

- Inner porosities

- Surface porosity that allow higher accumulations of plaque than the traditional alloys.

The brief overview of information about a such promising metal (for booming sectors like health care, for example) like titanium, shows how all the above mentioned disadvantages can appear essentially just in case of melting, and so these are totally avoided by the hot forging with appropriate furnace or press, alongside an expert consultant that can address the choice of the proper machine, and suggest the working modalities and of course guarantee an impeccable customer service that avoids criticalities and tensions at the moment of operativity starting.