Remote forging test

Case study: remote forging test for the acceptance of an entire line

A few weeks ago we carried out a forging test completely on-line.

Generally, it’s the customer who comes to Mecolpress site and follows all the agreed forging tests, the complete development of the necessary activities and the forging phases of the agreed parts.

For the customer this means in any case to travel, physically being absent for some days from the office and personal business, incurring more or less important costs … in conclusion facing challenges weighed down by the situation that has developed because of Covid-19.

In order to meet the need of our customer we have ensured that the forging test for the acceptance of the entire line, that has as cornerstone our ME350 hydraulic press, was carried out totally on-line.

Therefore, we proceeded this way:

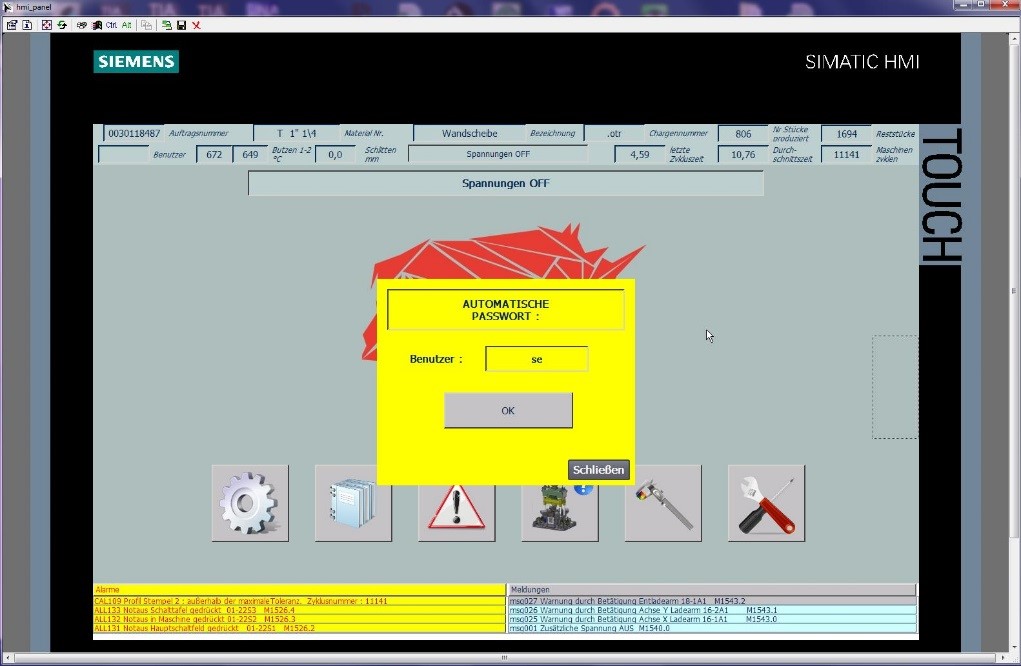

- The customer installs a software indicated by Mecolpress for a safe and certificated VPN connection.

- In this way a connection between customer internet and the press located in Mecolpress is established.

- Now the customer can access directly the machine operator panel.

4. We installed 2 video cameras, reachable by means of ip-adress, running for the whole production duration. The customer can follow the video live from any PCs.

5. Always only inside the established VPN it is possible to access through browser to the two cameras that are always on during the entire forging phase.

6. A technical support representative in Mecolpress is always and in any case available by telephone.

7. All the procedures regarding the setup phase and in particular the die changing phase are visible.

8. All the videos and pictures are therefore strictly confidential and visible from a webcam only to the customer that can save videos, if he considers it appropriate, or taking some pictures, everything always with the maximum confidentiality.

Which have been the advantages for our customer?

The advantages resulting from this acceptance-from-remote procedure of an entire hot forging line are easily identifiable:

- Time-saving,

- Costs-saving,

- Possibility that more people can follow the forging test, comfortably in front of a PC.

New procedures for remote tests

These methods of digital implementations are fundamental, but we still believe that in the world of precision mechanics and capital goods, the aspect of customer consultation is crucial and that as a result the personal contact is still necessary to carry out efficient projects according to partnership optics with the customer and to a deep understanding of his necessities.

Anyway, it is important to offer to our customers the alternative of remote forging tests. The customer experience is however total: video connections, real time data extraction, possibility to access to the press panel.

This procedure can bring also to future developments, for example, let’s think about how it can be useful if it would be set up on the contrary: a Mecolpress technician could have all the useful tools for diagnosing a problem on a machine located in Australia and solve it immediately! Without taking the plane, without taking a long journey, without charging important costs to the customers, avoiding long machine stops.

THE PRESS AUTOMATICALLY SEPARATES THE FORGED PARTS: GOOD IN ONE BOX, BAD IN ANOTHER!

Differentiated unloading of the forged pieces

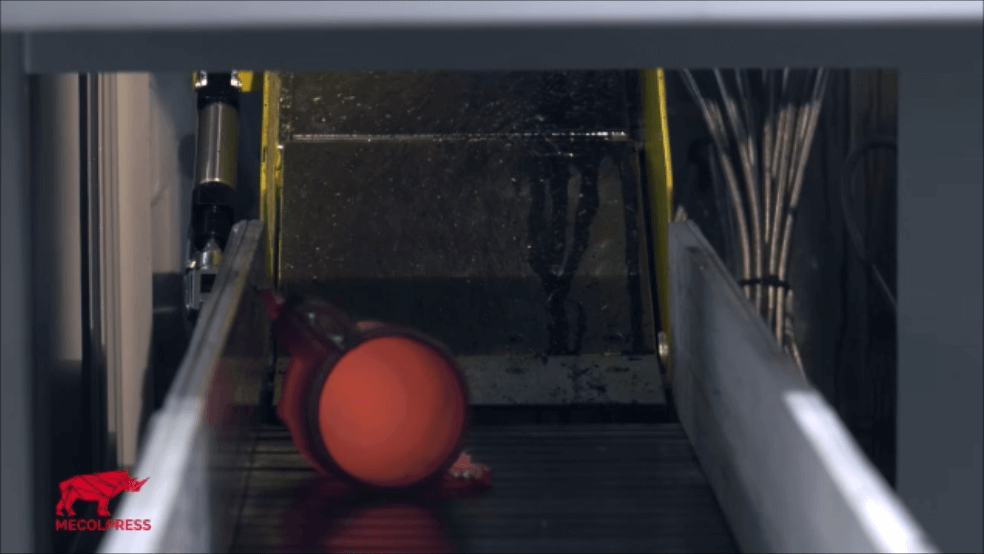

The press automatically separates the forged parts and divide them into different boxes. The press has become intelligent!

The differentiated unloading of the forged parts is an interesting function that Mecolpress provides by default on all hydraulic presses, but it can also be added as an option on eccentric mechanical presses.

Hot forging for higher quality of forged parts

The metal hot forging differs from the cold one because it allows you to obtain high quality pieces through an important deformation of the starting material. By working brass, copper, titanium, steel and aluminium by means of hot forging presses, in fact, it is possible to produce particular shapes, even with complex geometries.

The metal hot forging therefore allows to obtain parts that are more resistant than those obtained through other production processes.

In particular, metal hot forging can increase the strength and resistance of the products. For these reasons, the production of hot forged pieces guarantees specific advantages in their mechanical characteristics compared to those produced with other technologies such as casting or mechanical machining with chip removal.

The hot forging, compared to the casting processes, allows to obtain mechanical characteristics and surface appearance of superior quality. We at Mecolpress know it well, so much that we have made “Technology of Shape” our motto.

The piece produced must therefore be perfect, its quality must be certified. For this reason, Mecolpress has designed a system that allows the press automatically separates the perfect forged parts from those to be evaluated as they may not be such.

Why is it so important that the press separates the perfect forged parts from those to be evaluated?

From the automotive sector, the Lean production method teach us:

- Companies can be competitive on small production batches (producing only what is necessary) instead of manufacturing high quantities at low prices, with the risk of keeping high stock levels, are rewarded with success.

- The second must of the “Lean” work methodology is the zeroing of the waste and dispersions, or in other words, of the useless productions because of defected parts.

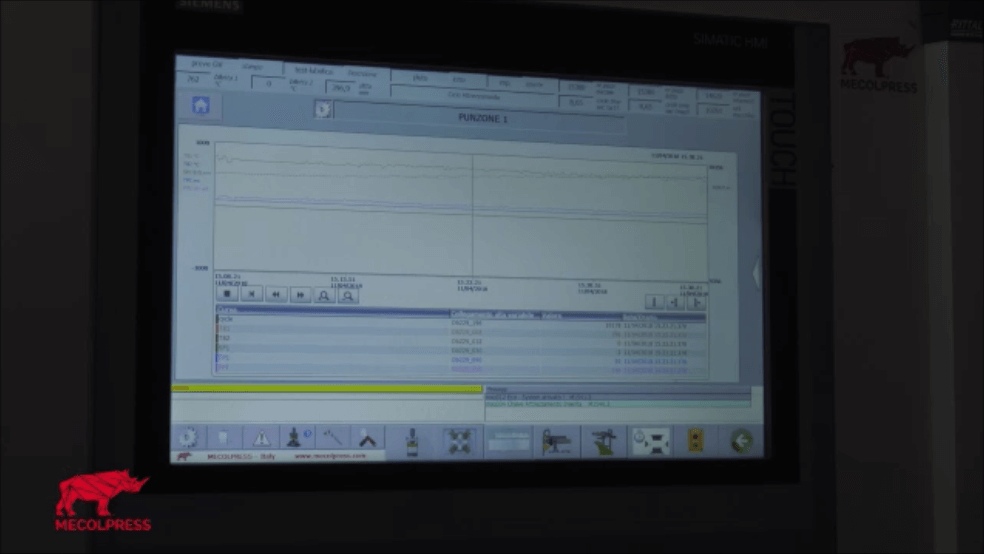

One of the most recurring needs in our customers is to have an ever more intense control of the forging process: the machine must be able to control as many parameters as possible important for the forging process, record them to make statistical predictions on the deviation from the optimal production, carry out checks.

Mecolpress offers a series of forging presses that fully meet the needs described above: the ME hydraulic series.

The hydraulic presses can control numerous process parameters and on these manage the logic for rejects or collect the measured values for statistical analysis. For example, they can control:

- the temperature of the billets to be loaded,

- the coring punches penetration time,

- the punches real penetration force,

- the final position reached by each punch.

Here you can learn more about the most important process parameters that hydraulic presses are able to evaluate.

The machines of the ME series have the credentials to be competitive in a modern and controlled forging field; they operate at their best on medium / small batches, thanks to their flexibility.

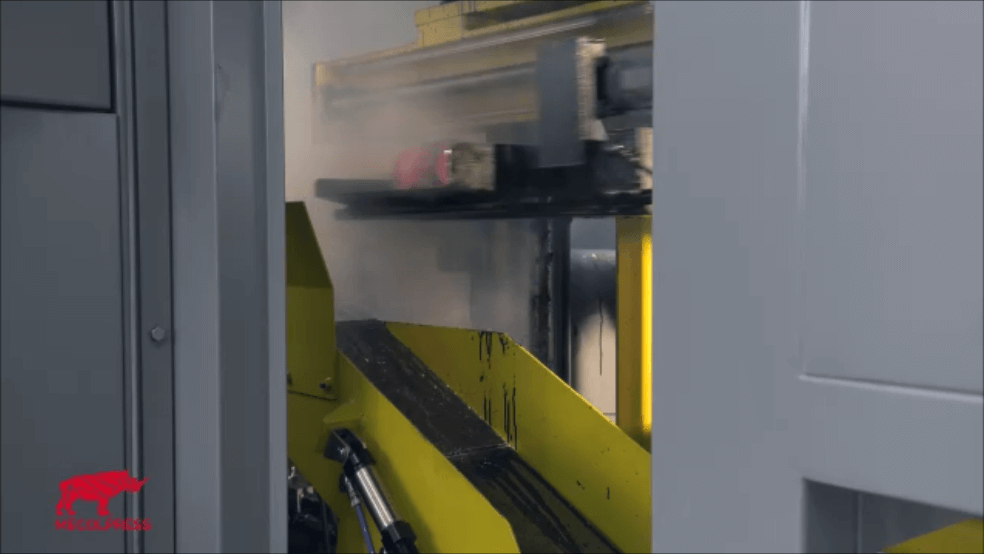

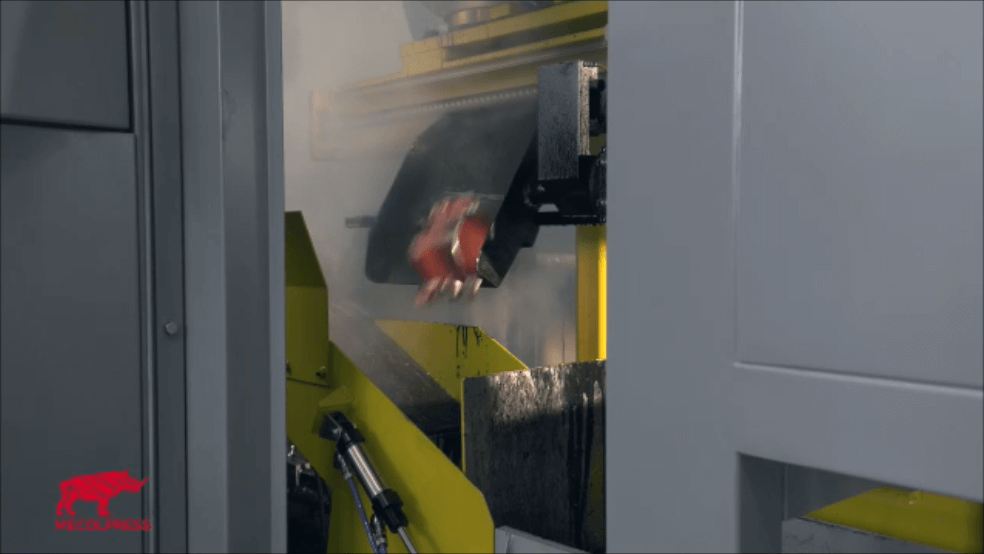

In this video we show how our hydraulic presses perform the differentiated unloading of the forged parts:

The pieces that do not fully comply with the process parameters set by the operator and analysed by our powerful Calipso software to control the forging process, are unloaded in a separate bin.

For the customer this operation translates into an important saving method:

- Less waste of time,

- Less material / pieces to be discarded,

- Be sure that the forged piece complies with the required characteristics,

- Get perfect shapes.

Industry 4.0

Hot forging becomes 4.0.

Our machines meet the requirements of industry 4.0.

The ME series hot forging hydraulic presses allow to control the speed, the sequence, the stroke and the force of each punch, allowing to print without any burr even some of the most complicated shapes. The production phases are programmed and monitored to get the best shape.

WHAT WE PROPOSE WITH OUR INDUSTRY 4.0 MACHINES?

- We program what the press must do;

- We program tolerance limits around a test cycle;

- We can control what the machine has actually done;

- The system verifies that the process is stable and identifies irregular anomalies or tendencies of deviation;

- We supervise and record parameters for at least 10,000 cycles;

- We provide a graphical representation of the process;

- All information can be sent to an external PC for further evaluation, registration and quality assurance purposes;

- The machine can send personalized messages to the supervisor, via email, to have full control over the performance of the equipment.

RESULT:

- To get precise analyzes and to make correct decisions;

- Have an automatic selection between compliant printed parts and irregular parts.

By ordering one of our machines you will be able to take advantage of the 250% hyper-depreciation. Contact us for further information