If the forging industrial process is stable and steady, it generates profit!

If the forging industrial process is stable and steady, it generates profit!

Today more than ever it is very important that the industrial process, in our case the hot forging one, remains stable and steady during operations time. As a matter of fact, by achieving this goal it is possible to generate profit.

The costs increase in raw materials, energy and specialized personnel is a more and more important and relevant constant for every manufacturing business. The profit of each order or job must always deal with these variables which can hardly be controlled.

The production stability can be controlled: the process must always be repeatable in the performances and must grant steady operative costs.

The metals hot forging is not an exception. Annual productions can reach tens of millions of pieces and each of these must be produced following the expected and planned parameters, the profit expectation must be guaranteed!

How is it possible to manage, monitor and correct tens of parameters, for millions of parts, granting the stability?

It is possible to grant the process stability even when millions of parts are produced and the process parameters are numerous, in this way:

01

=> monitoring the variability factors that influence each process to understand if they are under control or not by means of the statistical control.

02

=> Obtaining highest rigidities, forging force, and positioning precision.

03

=> Real time check of the behaviour of the main process parameters.

04

=> Modification of the main forging values without interrupting the production.

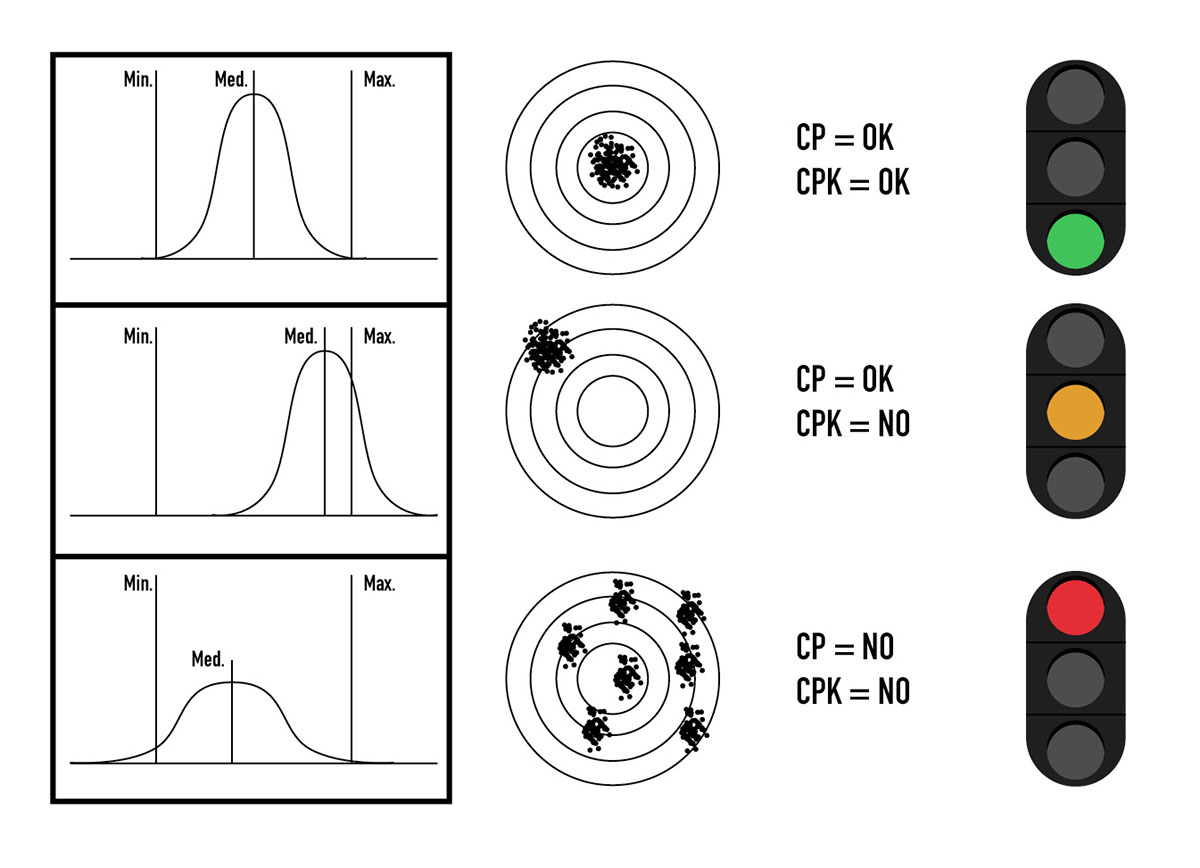

Statistics teaches that Cp and Cpk parameters are fundamental for controlling the progress of the forging process, for each variable in fact they are the key to understand its stability.

The example of the shooting with darts game allows you to quickly understand the concept:

a good Cp indicates that we are very repeatable in our shots, but it does not mean that we are hitting the target.

Only by obtaining a good Cpk, too, as a matter of fact, the optimal result is guaranteed!

=> Cp e Cpk must be much higher than one.

Let’s move on to a practical forging example:

-

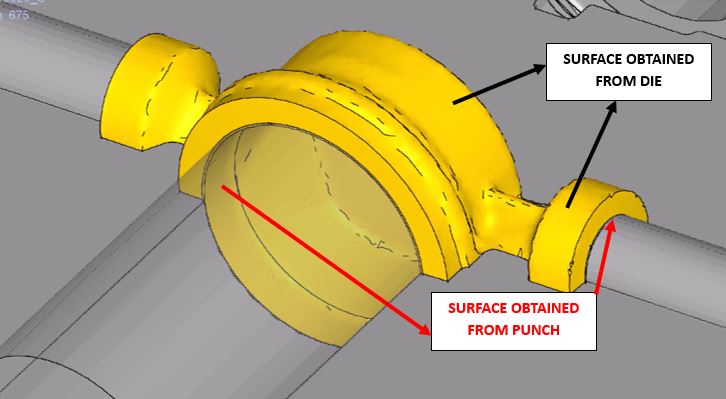

Forging a batch of 25,000 water meters.

-

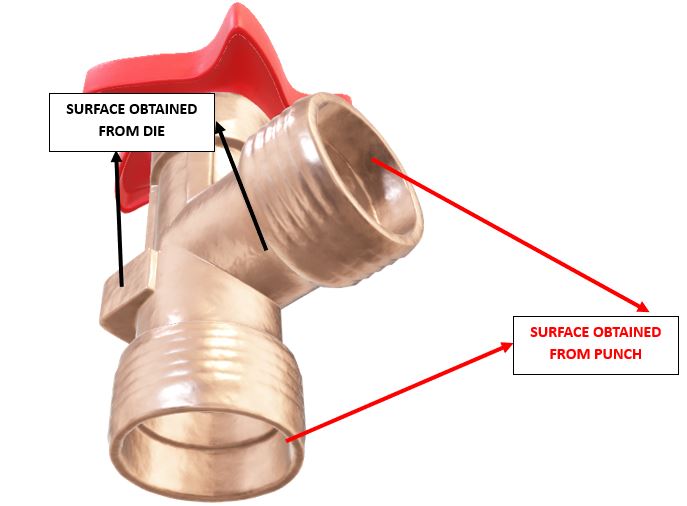

or forging a batch of 50,000 gas control valves

The dimensions of the forged parts are determined:

- by the surfaces of the part shape created in the die.

Cp depends on the presses rigidity performance and on the die design.

Cpk depends on the correct evaluation of the material shrinkage, which is related to the forging temperatures, to the part geometry and raw material chemical composition.

- by the punches involved in the material deformation.

Cp is obtained from punches rigidity and thrust force.

Cpk is obtained from the possibility to adjust the punch arrival position.

During the forging tests carried out with our customers from all over the world, the dimensional statistical analyses carried out on the produced samples (batches of thousands of pieces) have demonstrated that Cp and Cpk parameters were always abundantly and stably higher than one.

The complex geometries or the parts dimensions are not a problem.

How could we maintain the forging industrial process stable on our ME Hydraulic Presses?

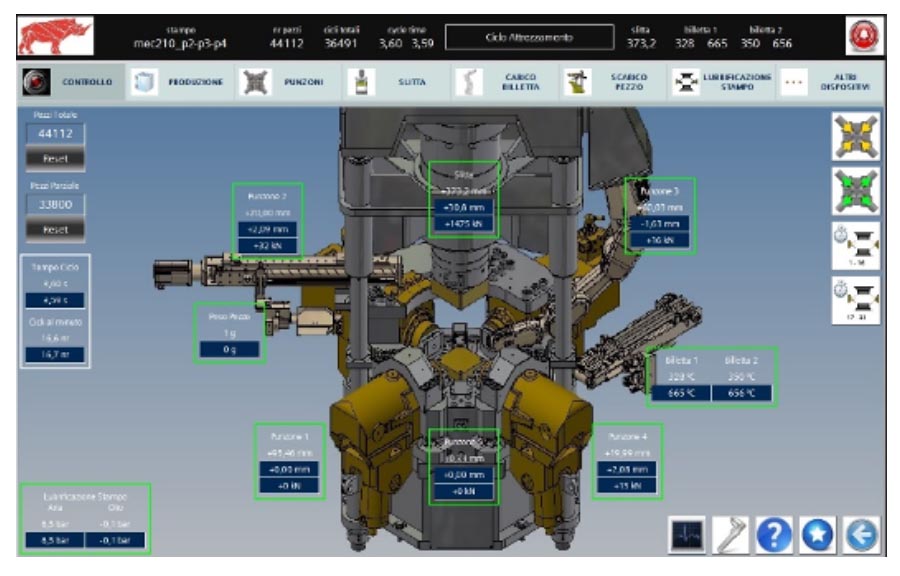

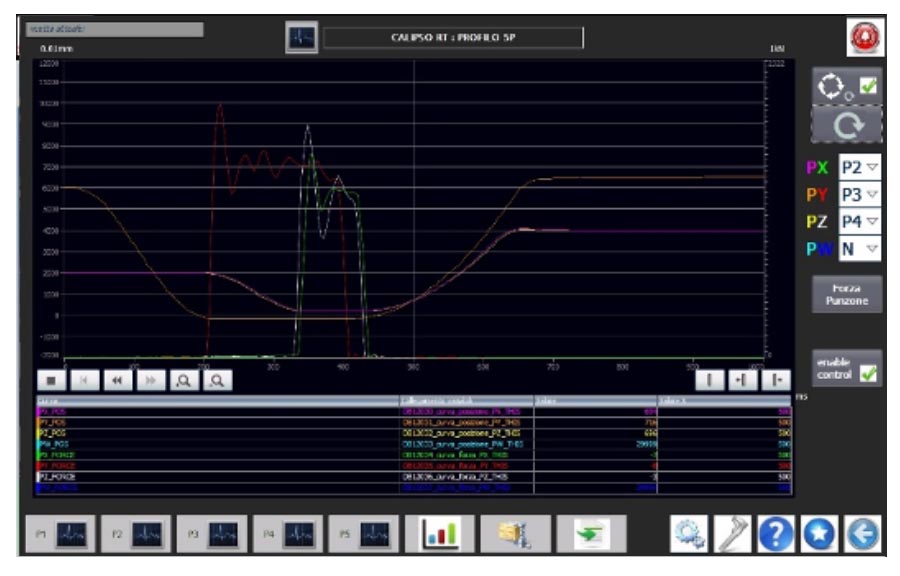

- Mecolpress presses are equipped with Calipso software for operative parameters setting and their continuous control. Calipso, software entirely developed by Mecolpress, allows you to control the main process parameters in real time (forging forces, position, speed, …). Even before measuring the pieces, it is possible to understand if the forging process is stable and guarantees constant performance.

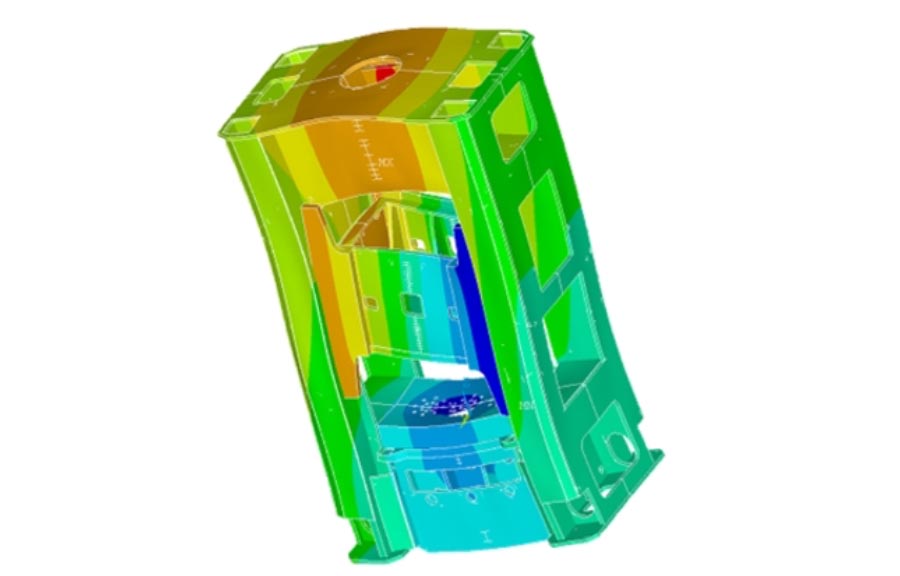

- Our presses are designed with advanced calculation systems (FEM) which allow to predict the rigidity of the components with the utmost precision, minimizing their deformations, even if subjected to high loads.

=> Cp under control

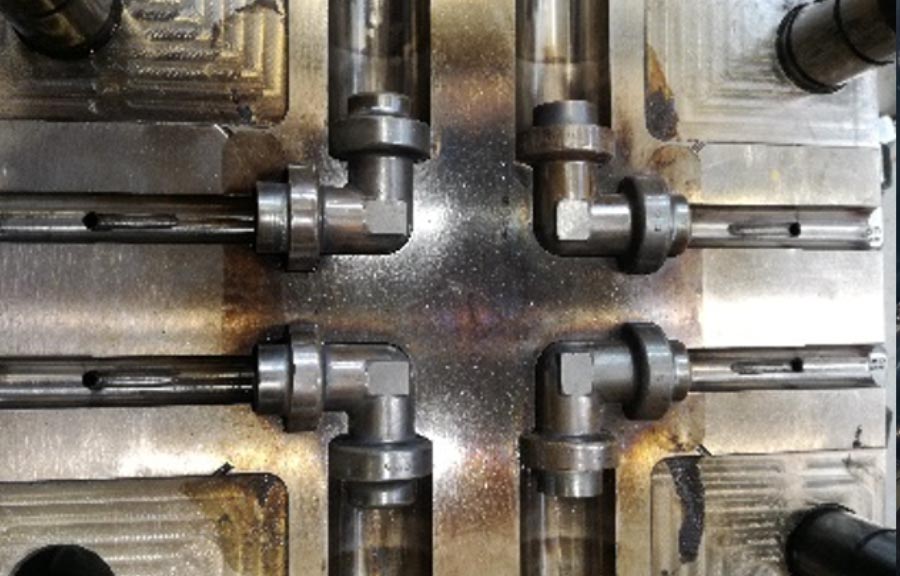

- We have designed our hot forging presses in order to have the highest possible dies closing force and maximum punch thrust force.

=> Cp under control

- The stroke adjustment of the individual punches occurs in real time, thus allowing the related dimensions to be modified during production.

=> Cp under control

- The long experience in dies design and the collaboration with the best specialized companies in the sector have allowed us to create the dies with extreme accuracy, in order to guarantee stable production of the pieces.

=> Cp under control

Reduced energy consumptions with the new hydraulic ME presses

The new Mecolpress ME hydraulic presses grant reduced energy consumptions.

How did we get to achieve this goal?

Mecolpress has been working with its customers for more than 50 years providing the best forging technologies that allow to maximize the quality of the products and the related productivity.

The forging process improvement needs do not always seem to proceed in the same direction:

- the energy consumption reduction requires the reduction of the installed power;

- the high productivity and the raw material reduction require increasing installed powers.

Our customers and partners are dealing with this conflict and are wondering how to come out as winners.

“Which is the most abundant existing source of energy? the least polluting, least expensive, most immediately available one: that is, energy saving …”

Piero Angela

What does Mecolpress propose to grant in the same page reduced energy consumptions and high productivity?

Mecolpress is not afraid of challenges, indeed it knows that these represent an opportunity to grow and improve.

Thanks to the continuous and accurate control system, Mecolpress presses determine and memorize the process parameters at every fraction of a second, i.e. the minimum force and speed requirements to obtain a certain product with the best characteristics. Under these values it is not possible to obtain an acceptable product.

Our long experience has allowed us to evaluate numerous forging cases, from small connectors of ½” up to large valves/water meters of more than 2”, in standard and lead-free brass grades.

To reduce power when it is not needed and to maximize it when it is needed! This is the secret.

The forging process control system

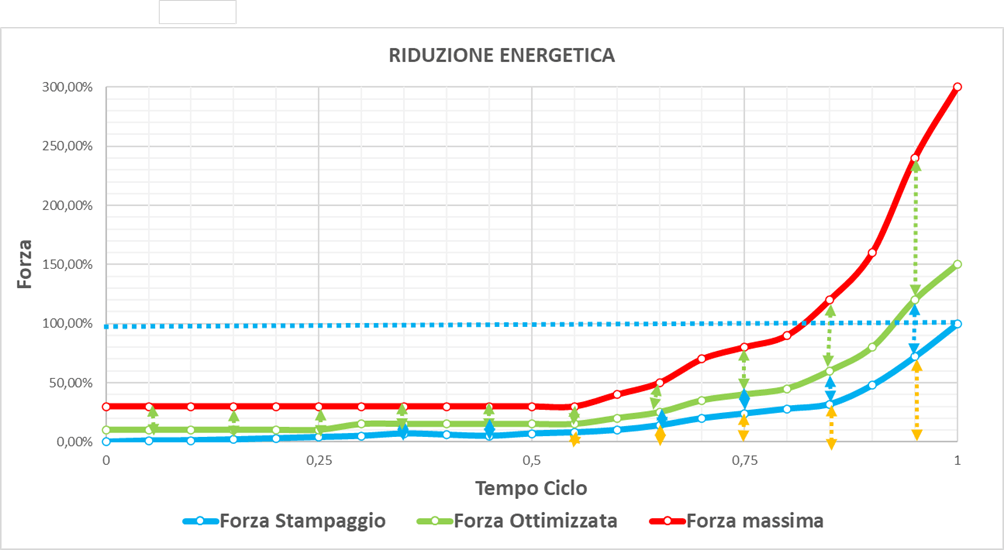

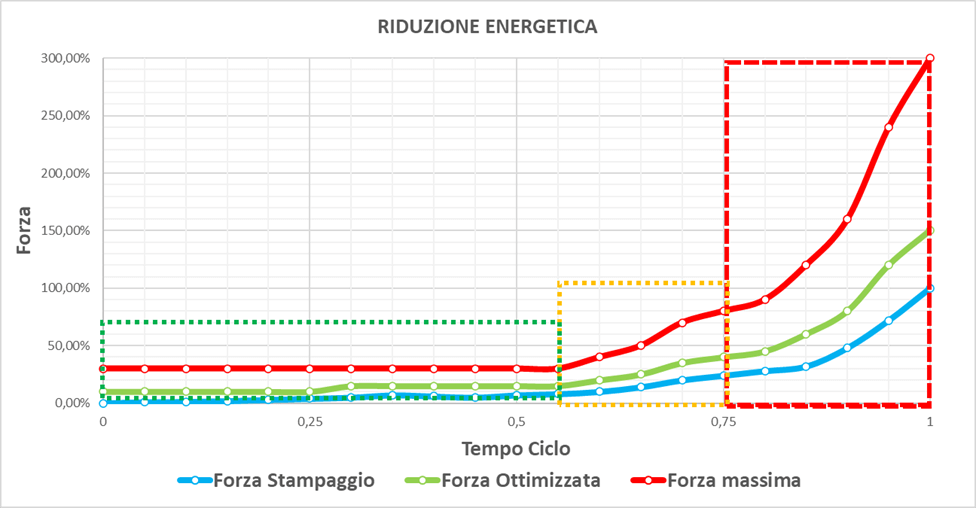

The press control system learns (ADAPTIVE CYCLE) the trend of the forging cycle and regulates the pressure and the flow of the oil (REGENERATIVE CYCLE) in order to get as close as possible to the minimum forging force. A reasonable safety margin is maintained in order to compensate for eventual external parameters variation (billet temperature, material quality, dimensional tolerances, …).

During the forging cycle Mecolpress press will have three phases: power reduction, transition, maximum power.

We monitored the flash-free forging process of the body of a 1 1/4″ ball valve with a productivity of 12 pieces per minute, therefore 720 pieces per hour.

Thanks to the ADAPTIVE-REGENERATIVE cycle the energy consumption is reduced by 50%, reaching an average consumption of 45kWh.

But let’s not forget the other advantages acquired:

- production capacity more than doubled compared to the traditional cycle,

- high repeatability of the piece quality (cp>2),

- constant compliance (cpk>1.33) with very tight dimensional tolerances (± 0.1),

- minimized material consumption thanks to over 6% flash-free forging,

- improved workability thanks to a more uniform internal conformation,

- increased product quality thanks to the elimination of internal defects.

A CUSTOMIZED TECHNOLOGY FOR THE PRESSES

Courtesy of Publitec

Magazine Deformazione N.281 FEBRURY 2023

of Aldo Biasotto

Mecolpress has chosen to make use of the customized solution proposed by Siemens, SIMAHYD, to ensure high reliability and better control of the forging process. This solution is combined with Simatic controllers, allowing both control of the hydraulic valves and management of the variable speed pumps.

Mecolpress is a company specialized in the production of machines and systems for hot forging.

Its story begins in 1969 in the Brescia area: here, for over fifty years, the company has been innovating and developing ever new solution to remain competitive on the worldwide market. The heart of Mecolpress beats in Flero (Brescia) where the technologies are designed and manufactured in an industrial area of 30,000 square metres, 10,000 of which are covered by buildings. With a staff of around 60 people, to date Mecolpress has distributed around 2,000 presses to customers in 60 countries all over the world. The context in which the company operates is broad and differentiated . At the beginning it was only focused in the brass hot forging applications, in particular in the production of fittings, valves and fashion products.

Later on, it was expanded to the world of steel, aluminium and special alloys applications, both hot and cold, thus embracing further sectors: automotive, industrial, medical, sports up to watches. To remain competitive on a global scale and bring an innovative contribution to the metal forging market, where the scenarios for the future are increasingly challenging, Mecolpress needed to rely on a top-level partner for technological components.

Thus was born the collaboration with Siemens, in particular regarding the electrical and electronic supply to the company. The goals: to ensure a high reliability in the presses functioning and better control of the forging process.

The way to reach these goals: SIMAHYD. “Siemens offers new solutions regarding power and process control, on a large scale and for different applications. To be successful, you need to be innovative in making your customer competitive: the synergy between Mecolpress and Siemens allows to reach this goal” says Maurizio Razio, Electrical Engineering Manager of Mecolpress.

The advantages of an open and customized package

To pursue this goal, Mecolpress therefore made use of the customized SIMAHYD solution. It is about a custom-built application package, specifically designed for Simatic S7-1500 controllers, which allows the control of hydraulic axes thanks to software modules that extend the functionalities of the original technological objects in Siemens controllers. In this way, both a control of the hydraulic valves and a management of the variable speed pumps are obtained.

The high level of flexibility of applications in the hydraulic sector facilitates a quick and simple control implementation: this was the case of Mecolpress technologies. By applying this solution to the presses, thanks to this package it was possible to ensure the control of the proportional valves on which the seven hydraulic cylinders depend. “The advantages of SIMAHYD open package are many: it allows to make the modifications necessary for integration into the hydraulic circuits of the machines, preserving the existing control program and, to facilitate the axes set-up, it also includes the display part, also It can be integrated into the existing operator interface.

Furthermore, this application is characterized by controller type “fail-safe”, which facilitates an integrated management of the entire machine safety”, explains Sergio Mazzon, OEM Business Developer of Siemens Digital Industries in Italy. Thanks to this customized solution, it was therefore possible to quickly manage the hydraulic power axes, such as those present on the ME Next Generation series presses, reaching extremely high precision and repeatability.

A technologies portfolio for each customer

Today Mecolpress can offer a complete portfolio of technologies according to the application needs of the Customers: eccentric mechanical or screw presses, hydraulic presses, auxiliary presses. The benefits are many and related to both the presses and the complete forging lines: high production capacity with reduced cycle times; high efficiency thanks to the minimization of energy, raw and semi-finished material consumptions; product quality control by monitoring process parameters; complete automation of the production cycle thanks to the reduced intervention of the operator; technologies allowing quick tooling change between one product and another one, in order to manage small production batches too; compatibility with industry 4.0 and arrangement for predictive analysis systems for maintenance and processes; remote or in person assistance service and spare parts warehouse suitable for a prompt response in case of need.

Thanks to the experience gained and the particular attention to innovation, today Mecolpress is able to face the growing challenges of the market head-on. “Thanks to a reliable partner like Siemens, our technologies are perceived as improving and taken into consideration for investments in new industrial assets. The prospects for growth in turnover and market share are solid and demonstrated by the numbers of the last two years and by the orders portfolio acquired” says Danilo Fagnani, Sales Manager of Mecolpress.