EXHIBITIONS 2025: MECOLPRESS AT FORGE FAIR (Cleveland)

FORGE FAIR 2025

We are waiting for you at booth 419 with our partner Forging Equipment Solutions.

Mecolpress will hold a presentation on Wednesday 14 May on the theme “Experiences About Ferrous and Nonferrous Hot Metal Forging”

BEST PERFORMANCE IN GREEN BRASS FORGING: DISCOVER THE INNOVATIVE MECOLPRESS SOLUTION

In recent years, all production sectors have been looking for sustainable and innovative solutions, seeking alternatives with low environmental impact, based on recycling, where possible, with particular attention to the health of all of us.

The international environmental policies are trying to reduce, as much as possible, the presence of potentially toxic materials in products that are on sale and in use.

The aim is to enable a circular economy that allows the recycling of components that have reached the end of their life, preventing them from representing a threat to the environment and health. The regulations launched in the United States and Europe (RoHS, ELV, CSPIA, DWD, ..) have been adopted by most of the world’s states or at least indicated as guidelines to follow.

A relevant part of the forged brass pieces is in contact with water, even drinking water, the presence of lead increases the risk of contamination, the use of lead-free brass alloys therefore limits the health risks.

In the production of brass, the material under investigation is precisely Lead, which has always been used as an alloy element to:

- improve workability on tool machines;

- improve the quality of cast products (low porosity);

- decrease contact friction.

The percentage of lead used in brass alloys goes from 1.5 to 3.5% and is incompatible with the target of limiting its presence to 0.1% for each homogeneous material.

Using lead-free brass alloys

The companies that are involved in hot forging of brass are therefore faced with the challenging choice of using lead-free alloys, but there is no shortage of doubts:

- What consequences could, this change in chemical composition, have on the production process?

- Can the current forging capabilities still be considered valid?

- What updating\improving should be planned in the forging department?

Over the past few years, we have worked to find the answers, and based on our experience we can therefore provide some practical adviceto successfully produce lead-free brass forged parts!

Sustainable forging, how to do it?

· Bar cutting

Cutting bars using rotating disc blades is recommended to ensure correct weight accuracy.

Tool steel/high speed steel (HSS) discs are no longer sufficient to guarantee an acceptable service life. It is necessary to switch to discs with tungsten carbide base material inserts (TCT).

Below we propose a balance of the pros/cons for each of your technologies, usually when the production of lead-free brass is around 70-80% total, TCT blades are economically advantageous.

| HSS BLADE | TCT BLADE |

| Low unit cost | High unit cost |

| Extremely short service life | High service life |

| Re-sharpenable | Not re-sharpenable |

| Reduced blade thickness | Reduced blade thickness |

Oil lubrication of the blade is necessary to reduce frictional heat.

The cutting precision must be extreme to avoid problems during the forging process, especially if it is without burr\flash. The cutting machine and the blade guidance system must have an extremely rigid body. The maximum error allowed is 0.1mm.

It is also suggested an optimization of the cutting process to minimize/eliminate material waste, given the ever-increasing costs.

Modern cutting technologies allow:

- 5mm head cuts;

- cutting of the same bar with different lengths to eliminate tail waste;

- differentiated unloading for the different cuts: head, length A and length B.

· Characteristics of lead-free brass

Lead-free brass has physical and mechanical characteristics that are very different from traditional brass.

| Standard Brass with Lead | Lead Free Brass | |

| Specific Gravity [g/cm3] | 8,5 | 8,3 |

| Thermal Conductivity [W/m] | 114 | 35 |

| Electrical Conductivity [%IACS] | 26 | 8 |

| Coefficient of Thermal Expansion [X10-6/℃] | 21 | 20 |

| Liquidus Temperature [℃ ] | 900 | 890 |

| Solidus Temperature [℃] | 885 | 855 |

| Tensile Strength [Mpa] | 435 | 650 |

| 0.2%Yield Strength [Mpa] | 295 | 450 |

| Elongation [%] | 25 | 20 |

| Hardness [HV] | 140 | 200 |

Lead-free brasses are tougher, more resistant and more refractory to heat transmission.

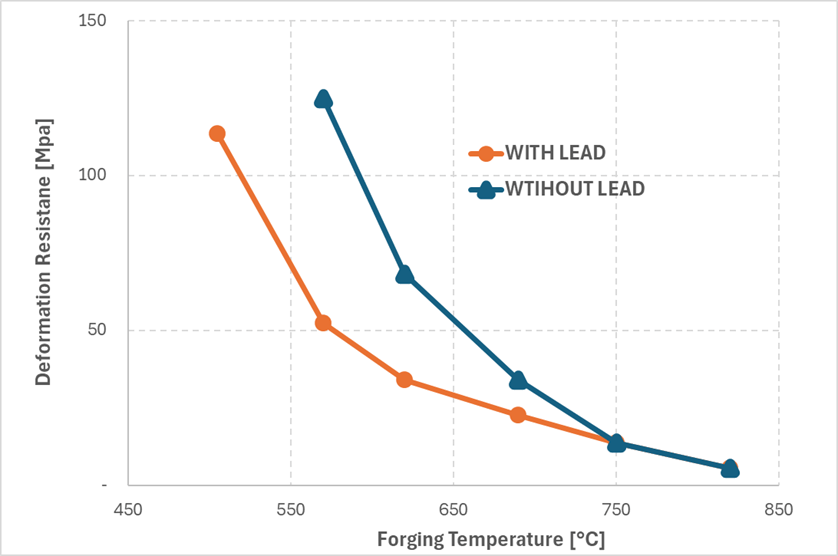

This trend is also confirmed when the heating temperature increases.

At the same heating temperature:

- Lead-free brass has a higher resistance to deformation value;

- Lead-free brass has a higher sensitivity to change in resistance to deformation in case of temperature variation.

Maintaining a heating temperature with the lowest possible variance (+- 5°C) is the key to have a reliable hot forging process.

The mechanical presses of a few decades ago were not designed with safety criteria that are suitable for these materials: simply because these materials did not exist at the time!

· Mechanical presses suitable for stamping lead-free brass

It is therefore essential to choose a press suitable for forging the new types of lead-free brass alloys.

Mecolpress SEO\HEAVY mechanical presses guarantee:

- Greater rigidity and safety margin of the structures (+50%) with capacity up to 700t.

- Greater safety margin of the transmission systems (up to +50% with epicyclic system).

- Hydraulic reaction cushions with increased capacity (+20%).

- Hydraulic cushions with SOFT IMPACT or OVERBOOST system to mitigate the impact force or increase the closing forces (+100%), with capacity up to 120ton.

- Air\oil lubrication system up to 30 points to lubricate and cool the critical points of the die (integrated\external).

- Water cooling of the most critical components.

- Hydraulic unlocking in the slide in case of overload to preserve the mechanical components.

- CALIPSO control system that memorizes the fundamental parameters for each die cycle to have full control of the process.

The ME hydraulic presses by Mecolpress guarantee:

- Net die closing force up to 350 tons.

- Thrust force of the lateral and vertical punches up to 240 tons.

- Maximization of flash-free die.

- Punch kinematics system that maximizes force in the final phases of the stroke.

- Air/oil lubrication system up to 30 points to lubricate and cool the critical points of the die (integrated/external).

- Water cooling of the most critical components.

- CALIPSO control system that memorizes the fundamental parameters for each die cycle to have full control of the process.

Don’t be caught unprepared, current regulations have started to reduce the use of lead and future ones will be even more restrictive, Mecolpress’s hot brass forging technology is ready to go!

EXHIBITIONS 2025: MECOLPRESS AT ISH (GERMANY)

ISH 2025

The world’s leading trade exhibition is the flagship and heart of the healthcare and HVAC industry, as well as a unique driver of innovation. ISH focuses on modern bathroom design, sustainable heating and air conditioning technology and smart home systems. Under the motto “Solutions for a sustainable future”, ISH 2025 will be launched with a new, clear and modern event structure.

It will be held from 13 to 17 March 2025 in Frankfurt at Messe Frankfurt.

We look forward to seeing you at our Booth, Stand Hall 9.1 Stand no. C91

Get your free admission ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

EXHIBITIONS 2025: MECOLPRESS AT TIMTOS (TAIWAN)

Timtos 2025

This exhibition will be held at Taipei Nangang Exhibition Center.

The global machine tool industry prepares for TIMTOS 2025, the international trade exhibition with the participation of more than 1,000 exhibitors.

TIMTOS 2025 represents a platform of excellence to discover technological innovations and advanced solutions for manufacturing production.

Mainly the exhibition focuses on three main macro-topics: AI & Robotics, Future Smart Manufacturing and Green Power & Sustainability.

For this reason, from 3 to 8 March 2025 Mecolpress will be at Stand Q0733.

Get your free ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

MIA: Mecolpress Artificial Intelligence

AUTOMATING THE OPERATION ASSISTANCE WITH ARTIFICIAL INTELLIGENT

We are pleased to communicate an important innovation in the hot forging sector: we have managed to successfully implement a solution based on Artificial Intelligence which adds considerable value to our assistance service!

Why have we decided to integrate the Artificial Intelligence in our Assistance service?

The implementation of a technology based on the artificial intelligence can significantly improve our assistance service:

- Reduction of technical support times

- Assistance automating for presses troubleshooting

- To provide access to manuals and guides 24 hours a day, 7 days a week

- To grant a prompt problem managing on the production lines.

- To directly obtain a multilingual support to meet the needs of customers all over the world.

- Autonomous and prompt problems managing directly on customer production lines.

- To have an immediate response to press alarms and signals.

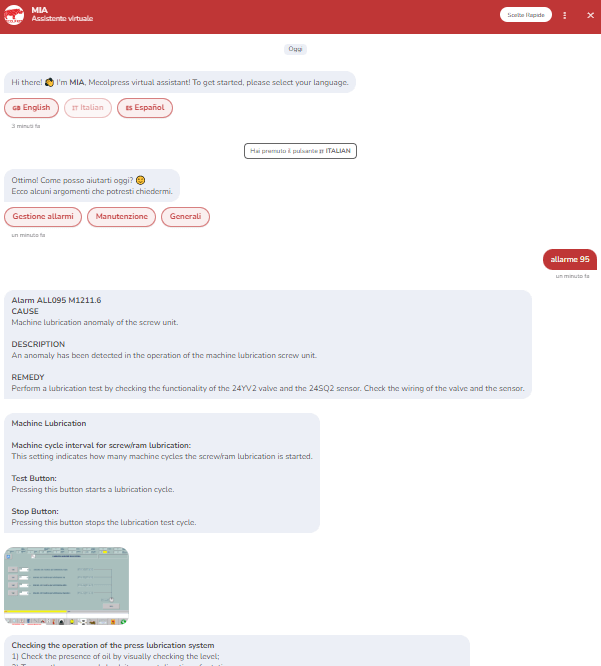

What exactly does MIA – Mecolpress Artificial Intelligence consist of?

MIA is a technology based on generative AI and Retrieval-Augmented Generation (RAG) to offer Mecolpress an advanced virtual assistant that supports technicians in the maintenance and troubleshooting of presses, 24 hours a day, 7 days a week.

The 3 MIA great adavantages

- Maintenance automation and Troubleshooting

The system developed by Userbot.AI has been trained on the manuals of Mecolpress machines and on the history of over 450 types of alarms, allowing operators not only to obtain immediate answers to technical questions directly from the production lines, but also to have instant support and with step-by-step guides for resolving critical alarms. Operators can consult information via tablet or smartphone, significantly reducing the time needed to resolve technical problems.

- Multilingual support

To facilitate access to information by international customers and operators, the virtual assistant has been implemented with multilingual functionality in Italian, English and Spanish, but also allowing translation into 100 other languages in real time thanks to Generative AI, thus ensuring fluid and understandable communication for all users.

- Customer Experience Improvement

The virtual assistant improves the customer experience, reducing waiting times and providing immediate and accurate responses 24 hours a day. This translates into reduced operational disruptions and a higher level of customer satisfaction. Furthermore, thanks to this new system, the digitalisation of information is achieved concretely, not just in words. Thanks to this project, the user has immediate access to all the information contained in the use and maintenance manual, which given the complexity of the machines, is over 1,000 pages.

Which are MIA goals?

Thanks to virtual assistance based on AI, we set ourselves the goal of obtaining significant results in terms of operational efficiency.

It is estimated that, once fully operational, the system can lead to:

- a 60% reduction in support/assistance times, allowing operators to obtain immediate answers to the most common questions without having to wait for technical support to intervene.

- to reduce the number of human support tickets by up to 40%. This result will be possible thanks to the automation of troubleshooting and quick consultation of manuals directly via the virtual assistant. In this way, requests that currently overload technical support can be managed independently by operators in real time.

- to create a smoother and more responsive customer experience, with a significant improvement in the quality of service offered by Mecolpress.

MIA future evolutions

In the future, Mecolpress plans to expand the use of the virtual assistant to other product lines, also extending support to new markets.

Furthermore, Mecolpress is considering using the bot to support its partners and resellers around the world, offering them easier access to technical information and product training.

Below is the article published on the Smeup website regarding our experience of implementing Artificial Intelligence in our assistance service:

Mecolpress: automating the operation assistance with AI

Here below you can find two quotes contained in the above-mentioned article:

“I am enthusiastic about the journey we are taking with Userbot.AI. I have always believed in innovation, and, thanks to this solution, we are able to provide immediate and continuous support to our operators around the world. I have involved a highly qualified team to work on the integration of our machine manuals and, so far, the results have gone far beyond initial expectations. I am sure that this technology will allow us to significantly improve our operational efficiency and technical support to customers. “

— Carlo Contri, Mecolpress Technical Manager

“The partnership with Mecolpress demonstrates how generative AI and advanced Retrieval-Augmented Generation (RAG) technologies can revolutionize technical assistance in the industrial sector. This project represents a concrete example of how artificial intelligence and large language models can enhance operational efficiency and radically transform the way companies approach maintenance and technical support even in highly innovative and technically complex environments such as that of Mecolpress.”

– Antonio Giarrusso, Userbot Executive President

EXHIBITIONS 2024: MECOLPRESS AT EUROFORGE conFAIR (MILAN)

EUROFORGE | conFAIR

This exhibition will be held at Allianz MiCo • Milan Convention Center, Italy from 22 to 23 October 2024.

The EUROFORGE conFAIR is the only European fair and conference specifically designed for the forging industry. At EUROFORGE conFAIR we bring together the best suppliers, the most innovative scientists and the leaders of the forging industry in order to discuss the threats and opportunities of the current industrial megatrends and their effects on the forging world.

For this reason, from 22 to 23 October 2024 Mecolpress will be in Milan at EUROFORGE | conFAIR at Hall 3 Stand 130.

Experiences about ferrous and not ferrous hot metal forging presentation

You are invited to participate in the Experiences about ferrous and not ferrous hot metal forging presentation which will be held on Wednesday 23 Oct 2.00-2.30pm at the 2023 Confair Euroforge in Milan .

It will be a useful opportunity to learn about the latest proposals regarding:

- the reduction of the consumption of raw materials.

- the reduction of electricity consumption.

- high production capacity and flexibility in product changes;

- continuous quality control of the forging process;

- operational continuity thanks to after-sales assistance.

We will be proud to have your attention and to answer your questions and requests for clarification.

EXHIBITIONS 2024: MECOLPRESS AT CASTFORGE (GERMANY)

CastForge 2024

Stuttgart Trade Fair Center from 4 to 6 June.

Today costumers of the “Casting and Forging” field are looking for high-quality products ready for installation. As complexity and specific requests are constantly increasing, it is essential to stay on top with the latest news.

This Exhibition represents an important opportunity to meet face to face and discuss these topics in one of the largest markets in Europe.

For this reason, from 4 to 6 June 2024 Mecolpress will be in Stuttgart at Castforge Hall 5, Booth 5A37.

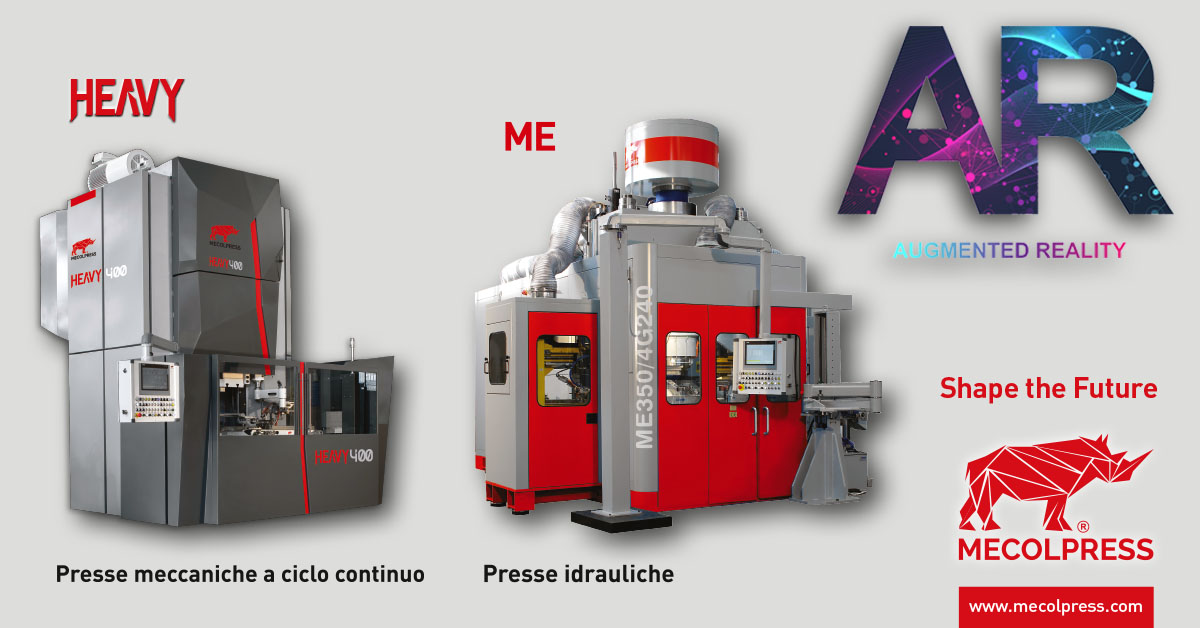

Augmented Reality, the press just a click away

On our stand it will be possible to view 2 Augmented Reality presses: ME hydraulic press and Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

MCE EXHIBITION IN MILAN + OPEN DAYS IN MECOLPRESS

MCE EXHIBITION IN MILAN

For over 60 years MCE – Mostra Convegno Expocomfort (Milan) has been a key event for innovative air conditioning and energy efficiency technologies.

Companies that design, build and install systems for the heating and air conditioning of industrial, civil and commercial environments meet to exchange experiences, find new Customers and strengthen collaborative relationships.

The value of the global HVAC market is estimated at more than 200 billion dollars and is expected to reach close to 300 billion in 2027. The increase in “smart” applications in the construction of buildings, the demand for increasingly efficient systems to deal with growth in energy costs, the greater demand for cooling systems in areas where they were not previously necessary, drive this growth in value.

INNOVATION, SUSTAINABILITY and ENERGY EFFICIENCY will be the cornerstones of this edition which will combine digital events and in-person meetings. The former facilitate the reduction of distances and communication ease, the latter allow us to consolidate relationships and better understand needs.

Looking forward to meeting you at MCE – Mostra Convegno Expocomfort

12-15 March 2024

at Milan Exhibition at booth T22 Hall 4 Milan Exhibition, Rho (MI)

MECOLPRESS OPEN HOUSE

Concurrently with the presence at Milan Exhibition, Mecolpress has decided to inaugurate some Open House days and give you the opportunity to see some of our machines directly in our factory.

All our last and innovative mechanical presses (HEAVY\SEO), hydraulic presses (ME) and screw presses (FDS\TDS) will be available to be seen in assembly/testing phase.

Looking forward to meeting you in Mecolpress on the occasion of our Open Days

11-15 March 2024

For further information and to get a free entry ticket to MCE Exhibition, contact us on +39 030 2560110 or write to us at sales@mecolpress.com

Exhibitions 2024: Mecolpress at AHR (U.S.A.)

AHR 2024

AHR EXPO – CHICAGO

The largest event in the HVACR industry returns to Chicago.

Three days dedicated to the latest energy saving solutions and sustainable technology in the field of heating, ventilation and air conditioning systems.

It will be held from 22 to 24 January 2024, in Chicago at McCormick Place .

We look forward to seeing you at our Booth: South Building – Stand S10262

Mecolpress presents the latest innovations in the field of brass hot forging:

- SEO and Heavy mechanical eccentric presses from 320 to 600 tons, high productivity up to 40 strokes per minute.

- ME series hydraulic presses: flash-free forging with significantly reduced energy consumptions.

- Direct drive screw presses: suitable to produce parts having complex geometry!

Augmented Reality, the press just a click away

On our booth it will be possible to view two presses in Augmented Reality: ME and Heavy series.

This technology allows to overlap multimedia information on the reality framed by the camera of your mobile device, smartphone and/or tablet, enriching the vision of the surrounding space with additional digital contributions.

Get your free admission ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

Reduced energy consumptions with the new hydraulic ME presses

The new Mecolpress ME hydraulic presses grant reduced energy consumptions.

How did we get to achieve this goal?

Mecolpress has been working with its customers for more than 50 years providing the best forging technologies that allow to maximize the quality of the products and the related productivity.

The forging process improvement needs do not always seem to proceed in the same direction:

- the energy consumption reduction requires the reduction of the installed power;

- the high productivity and the raw material reduction require increasing installed powers.

Our customers and partners are dealing with this conflict and are wondering how to come out as winners.

“Which is the most abundant existing source of energy? the least polluting, least expensive, most immediately available one: that is, energy saving …”

Piero Angela

What does Mecolpress propose to grant in the same page reduced energy consumptions and high productivity?

Mecolpress is not afraid of challenges, indeed it knows that these represent an opportunity to grow and improve.

Thanks to the continuous and accurate control system, Mecolpress presses determine and memorize the process parameters at every fraction of a second, i.e. the minimum force and speed requirements to obtain a certain product with the best characteristics. Under these values it is not possible to obtain an acceptable product.

Our long experience has allowed us to evaluate numerous forging cases, from small connectors of ½” up to large valves/water meters of more than 2”, in standard and lead-free brass grades.

To reduce power when it is not needed and to maximize it when it is needed! This is the secret.

The forging process control system

The press control system learns (ADAPTIVE CYCLE) the trend of the forging cycle and regulates the pressure and the flow of the oil (REGENERATIVE CYCLE) in order to get as close as possible to the minimum forging force. A reasonable safety margin is maintained in order to compensate for eventual external parameters variation (billet temperature, material quality, dimensional tolerances, …).

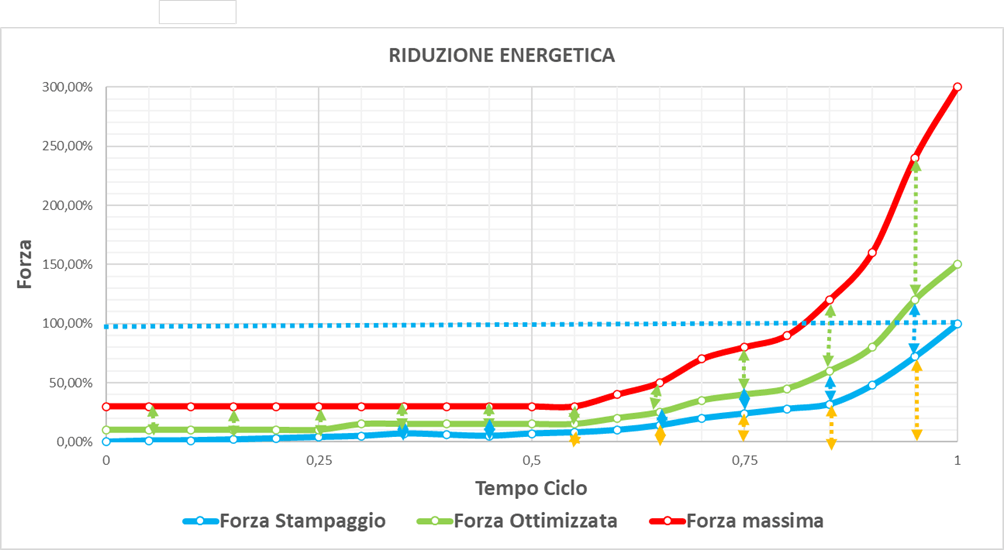

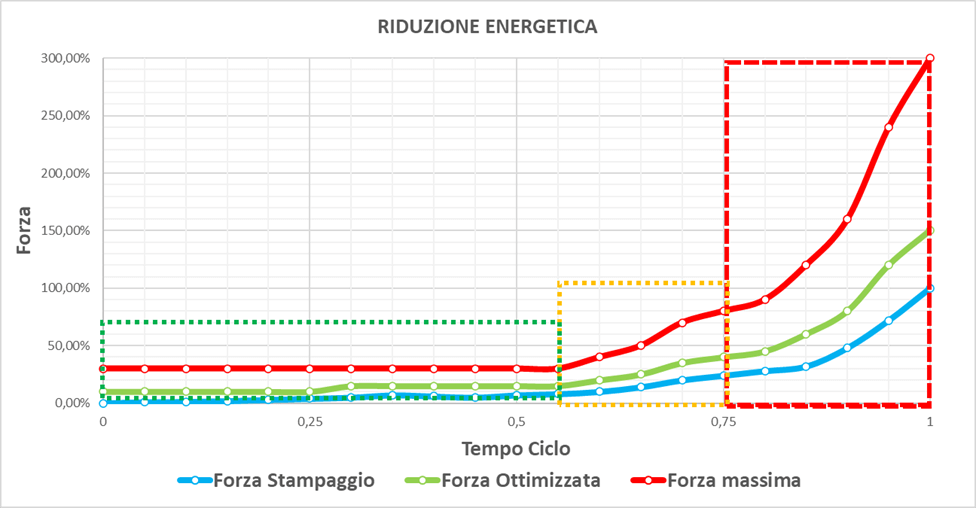

During the forging cycle Mecolpress press will have three phases: power reduction, transition, maximum power.

We monitored the flash-free forging process of the body of a 1 1/4″ ball valve with a productivity of 12 pieces per minute, therefore 720 pieces per hour.

Thanks to the ADAPTIVE-REGENERATIVE cycle the energy consumption is reduced by 50%, reaching an average consumption of 45kWh.

But let’s not forget the other advantages acquired:

- production capacity more than doubled compared to the traditional cycle,

- high repeatability of the piece quality (cp>2),

- constant compliance (cpk>1.33) with very tight dimensional tolerances (± 0.1),

- minimized material consumption thanks to over 6% flash-free forging,

- improved workability thanks to a more uniform internal conformation,

- increased product quality thanks to the elimination of internal defects.