EXHIBITIONS 2025: MECOLPRESS AT ISH (GERMANY)

ISH 2025

The world’s leading trade exhibition is the flagship and heart of the healthcare and HVAC industry, as well as a unique driver of innovation. ISH focuses on modern bathroom design, sustainable heating and air conditioning technology and smart home systems. Under the motto “Solutions for a sustainable future”, ISH 2025 will be launched with a new, clear and modern event structure.

It will be held from 13 to 17 March 2025 in Frankfurt at Messe Frankfurt.

We look forward to seeing you at our Booth, Stand Hall 9.1 Stand no. C91

Get your free admission ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

EXHIBITIONS 2025: MECOLPRESS AT TIMTOS (TAIWAN)

Timtos 2025

This exhibition will be held at Taipei Nangang Exhibition Center.

The global machine tool industry prepares for TIMTOS 2025, the international trade exhibition with the participation of more than 1,000 exhibitors.

TIMTOS 2025 represents a platform of excellence to discover technological innovations and advanced solutions for manufacturing production.

Mainly the exhibition focuses on three main macro-topics: AI & Robotics, Future Smart Manufacturing and Green Power & Sustainability.

For this reason, from 3 to 8 March 2025 Mecolpress will be at Stand Q0733.

Get your free ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

EXHIBITIONS 2024: MECOLPRESS AT CASTFORGE (GERMANY)

CastForge 2024

Stuttgart Trade Fair Center from 4 to 6 June.

Today costumers of the “Casting and Forging” field are looking for high-quality products ready for installation. As complexity and specific requests are constantly increasing, it is essential to stay on top with the latest news.

This Exhibition represents an important opportunity to meet face to face and discuss these topics in one of the largest markets in Europe.

For this reason, from 4 to 6 June 2024 Mecolpress will be in Stuttgart at Castforge Hall 5, Booth 5A37.

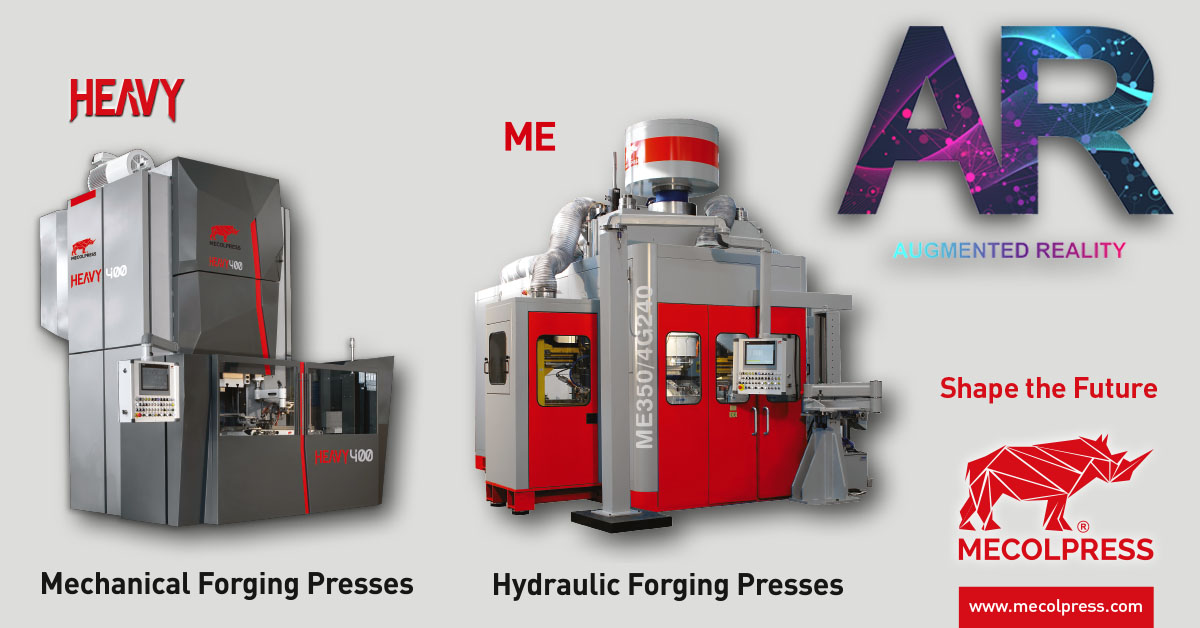

Augmented Reality, the press just a click away

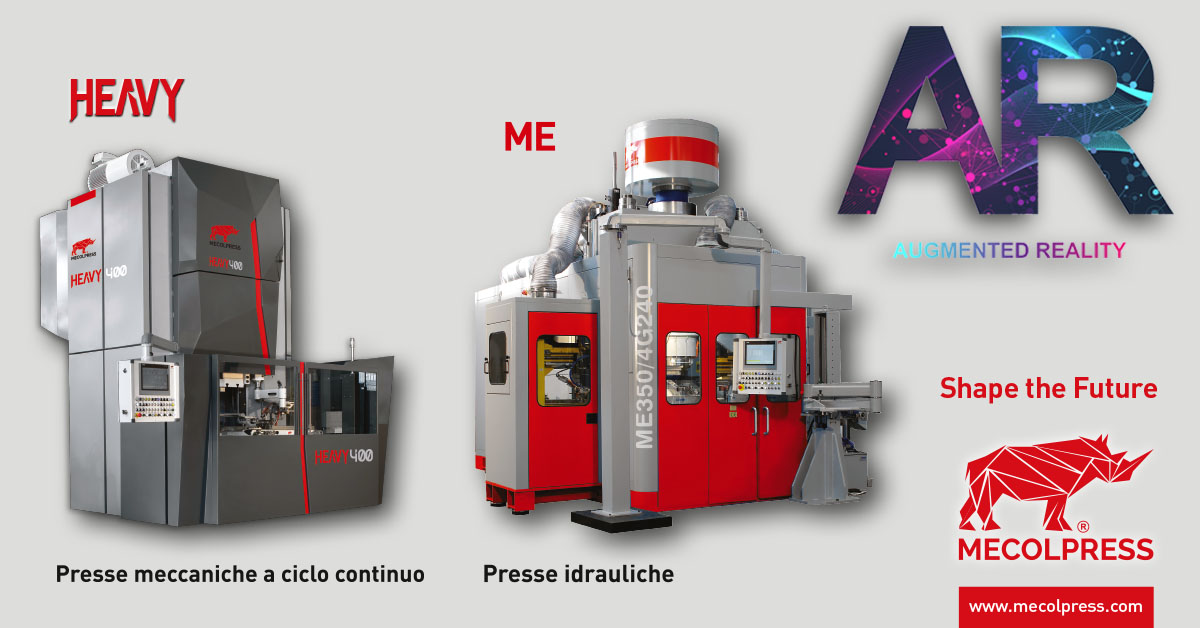

On our stand it will be possible to view 2 Augmented Reality presses: ME hydraulic press and Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

Exhibitions 2024: Mecolpress at AHR (U.S.A.)

AHR 2024

AHR EXPO – CHICAGO

The largest event in the HVACR industry returns to Chicago.

Three days dedicated to the latest energy saving solutions and sustainable technology in the field of heating, ventilation and air conditioning systems.

It will be held from 22 to 24 January 2024, in Chicago at McCormick Place .

We look forward to seeing you at our Booth: South Building – Stand S10262

Mecolpress presents the latest innovations in the field of brass hot forging:

- SEO and Heavy mechanical eccentric presses from 320 to 600 tons, high productivity up to 40 strokes per minute.

- ME series hydraulic presses: flash-free forging with significantly reduced energy consumptions.

- Direct drive screw presses: suitable to produce parts having complex geometry!

Augmented Reality, the press just a click away

On our booth it will be possible to view two presses in Augmented Reality: ME and Heavy series.

This technology allows to overlap multimedia information on the reality framed by the camera of your mobile device, smartphone and/or tablet, enriching the vision of the surrounding space with additional digital contributions.

Get your free admission ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

EXHIBITIONS 2023: MECOLPRESS AT FORGE FAIR (OHIO)

Forge Fair 2023

The United States of America is the country with the highest Gross Domestic Product and has always represented the reference point for the world economy. The tradition of the US manufacturing industry is long-standing and its importance is always growing in every sector. PRODUCTLY MADE IN THE USA!!

Mecolpress with its 50 years of experience in hot metal forging is proud to make its know-how available to make American customers and partners more competitive. Mecolpress has started this process since the 70s and hasn’t stopped yet.

We are proud to announce our presence at Forge Fair 2023 which will be held in Cleveland (Ohio) from May 23rd to 25th. Forge Fair, organized by the Forging Industry Association, is the largest and most important event in North America exclusively dedicated to metal stamping and forging. It will be a pleasant opportunity to discuss and connect the main industrial players in the sector with the aim of increasing their knowledge of production processes and improving them as much as possible.

Mecolpress presents the latest innovations related to forging technologies:

- SEO and HEAVY eccentric mechanical presses from 320 to 600 tons, high productivity up to 40 strokes per minute.

- ME series hydraulic presses: forging without burr with significantly reduced energy consumption.

- Direct drive screw presses: to produce parts with complex geometry.

Smart Brass Forging Presentation

You are invited to participate in the SMART BRASS FORGING presentation which will be held on Tuesday 23 May 3.20-3.45 pm (ET), a useful opportunity to learn about the latest proposals regarding:

- the reduction of the consumption of raw materials.

- the reduction of electricity consumption.

- high production capacity and flexibility in product changes;

- continuous quality control of the forging process;

- operational continuity thanks to after-sales assistance.

We will be proud to have your attention and to answer your questions and requests for clarification.

Augmented Reality, the press just a click away

On our booth it will be possible to view two presses in Augmented Reality: ME and Heavy series.

This technology allows to overlap multimedia information on the reality framed by the camera of your mobile device, smartphone and/or tablet, enriching the vision of the surrounding space with additional digital contributions.

Mecolpress together with its USA partner Forging Equipment Solution, awaits you at Stand 329 – Exhibit Halls A-B

Smart Brass Forging

We report the article below FIA Magazine, the Forging Industry Association, that speacks of us.

Smart Brass Forging

By Danilo Fagnani

MECOLPRESS started their activities in Brescia (Italy) more than 50 years ago, in 1969, providing solutions for the hot brass forging industry. MECOLPRESS then widened its portfolio including hot forging steel, aluminium, titanium, and special alloy applications. MECOLPRESS is now offering the most modern technologies available for mechanical (HEAVY family), hydraulic (ME Family) and screw driven (TDS, FPN family) presses.

The region of Brescia, located East of Milan, is generally considered the cradle of brass production, at least 20% of the total world production is firmly located here. The Brescia region is still able to compete with Chinese brass manufacturers (35% of the brass total world production) even if the production costs are not comparable in terms of manpower, energy and etc… The secret of this success is the know-how of the full brass production chain, industrially started from the 19th century, from melting process passing through forging then achieving the final product completion. MECOLPRESS was born and built in this interesting and dynamic environment, participating and contributing to solve the main challenges of brass producers (Smart Brass Forging).

These challenges are cyclically recurring in the market, and they can be summarized as follows:

- raw materials availability and costs;

- high variability in the market for parts from the peaks of high demand to small lots with frequent parts changeovers;

- difficulties to find the necessary manpower, from highly skilled operators, to maintenance technicians, to standard operations workers;

- availability to grant the best products quality reducing the non- compliant ones;

- reduction of the energy consumption approaching the green economy

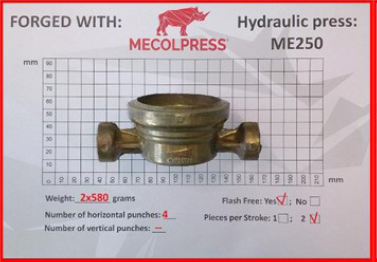

MECOLPRESS is supplying to the market the most powerful hydraulic presses (ME family) offering horizontal\vertical coring performances achieving:

- flash-less forging;

- reduced part material thicknesses;

- deeper and deeper punch coring

These features drive achieving parts with less weight and avoiding any further downstream process as trimming. ME hydraulic presses family (more than 60 units supplied from 2010) has standard sizes:

- 100 to 500t as die closure force

- 30 to 350t of punch coring force

The coring punches have independent movement guiding and optimizing the flow of material inside the die’s cavity. The punches forces, speeds, displacement sequences can be flexibly implemented in the HMI operator panel depending by the products to be forged (Smart Brass Forging). One of the four horizontal punches can be orientable (without losing coring force!) with the variable angle from from 0 to 45° allowing sloping coring for the parts.

The ME family hydraulic presses grant production performances that, depending by the equipment size, can reach up to 30 cycles per minute and they allow to forge multiple parts per stroke, throughout of some thousands of parts per hour is easily achievable. This will allow to complete productions lots is shortest time even if they are relevant in the number of parts to be reached. If the market conditions are changing and the market moves to lower number of parts per lot with frequent shifting between the products, the quick dies changing system will allow to dramatically reduce the down time. The fully automatic tools locking\unlocking and the servo-moved supporting arms allow one operator to accomplish the change in the quickest time (about 15-20min), in the complete safety conditions and without the help of any tools (Smart Brass Forging).

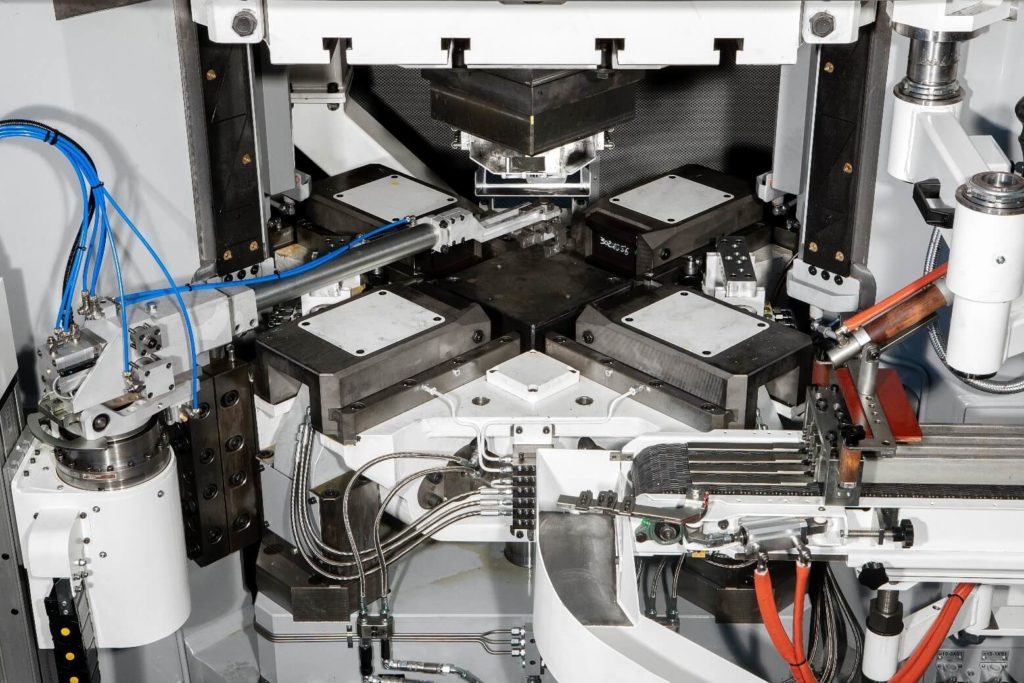

Mecolpress ME Next Generation series hydraulic press hot forging EG coring tool

The MECOLPRESS policy to reserve relevant stock of spare parts for all the presses that have been supplied is a key point to avoid unwanted down time in case of maintenance of the equipment.

Mecolpress ME Next Generation series hydraulic press outstanding parts weight reduction

MECOLPRESS is developing all of the control software for the presses: CALIPSO (Smart Brass Forging). This user interface is based on a touch screen model, it is very easy and intuitive, and it has been developed in several different languages; it allows any end user operator to work with continuity on the press and it does not require any particular skills or knowledge. Many functions have been simplified as input parameter requests to reduce the human factor effect in the press working conditions. CALIPSO defines and controls automatically all the ME family presses operations, from raw material loading up to forged parts unloading. The main parameters of each product receipt are saved in the internal memory, and can be easily retrieved for future production and transferred to customer MES\MRP. The press has an Ethernet OPC-UA connection module that grants this function as well the remote teleservice assistance by the MECOLPRESS technicians.

The MECOLPRESS R&D department is able to define the optimized process parameters and/or the best die geometry through FEA software which allows them to analyze both material flow and forging force. This on-demand service is appreciated by customers who are searching for a reliable supplier.

ME hydraulic presses can be paired with all types of furnaces: billets, bars, natural gas, electric induction, keeping in mind that the reliability on the heating temperature, the billet weight tolerance and the material metallurgical microstructure properties are key parameters to grant effective flash-less process success.

High production capacity, flexibility to switch from one product to another and high equipment reliability vanish if the forging process is not under full control. CALIPSO software is leading the game supporting the customers to control, with minimal effort. The forging forces, punches displacement parameters and sequencies, billets temperature, and so on can be monitored in the maximum\ average values or continuously during the working cycle. The desired thresholds can be set in the system to monitor the trends of the parameters and if any mismatch is found, the parts can be diverted automatically to the dedicated collecting box for further checking.

MECOLPRESS is fully committed to be an effective part of the green transition of the industry, reducing the energy consumption, pollution emission, and media consumption. This application shall not decrease or compromise the outstanding powerful performances of the ME family presses. CALIPSO and in-house engineering are the main characters of this target:

- hydraulic auto-adaptive regenerative function circuits;

- ECO mode for working pressure optimization;

- actuators optimized geometry;

- flexible set up of the operating pressure;

- AC frequency converters\variable flow hydraulic pumps;

- CALIPSO software that learns from experience optimizes the working parameters without relevant operator required intervention (Smart Brass Forging)

Mecolpress ME Next Generation series hydraulic press main view

These points collaborate to reduce the energetic consumption up to 50% in comparison with standard technology presses.

The dies lubrication system, very important in the flash-less forging, is using innovative pipe to pipe technology supplying alternative air and oil flows just with the needed quantities. All the dies lubrication parameters are set into the control software and up to 30 points can be reached; they can be integrated into the dies or with external nozzles. The proper pumps are installed on the machine bottom to collect all the remaining quantity of oil avoiding any overflow. The press lubrication is selective and only the components active are reached by the media, proper collecting box avoid leaking. No more waste of fluids!

Pressa idraulica Mecolpress ME Next Generation: esempi di particolari stampati a caldo senza bava

Mecolpress ME Next Generation series hydraulic press four parts flash less hot forging examples

The innovative suction hood embedded in the press structure collects the emission very close to the sourcing point, decreasing any possible spread into the environment and granting the best cabinet inside view of the process to the operators.

As all MECOLPRESS products, the ME series fulfills the most severe international safety standards and can be produced in compliance with North American and Canadian ones.

Danilo Fagnani Sales Manager Mecolpress

Danilo Fagnani Sales Manager Mecolpress Spa

Phone: +39-030-2560110

Email: d.fagnani@mecolpress.com

Exhibitions 2022: Mecolpress at GLOBAL INDUSTRIE (France)

Global Industrie Paris 2022

In three editions, Global Industrie has established itself as one of the leading exhibitions in the world dedicated to industry.

Its resolutely modern positioning geared both to the industry of the future and to international business explains the success encountered by its previous editions held in even years in Paris and odd years in Lyon. A geographical diversification which enables it to enhance both its offer and the variety of its visitors.

Global Industrie returns to the capital from the 17th to the 20th of May, at Paris Nord Villepinte.

We are waiting for you Stand 6M91

Augmented Reality, the press just a click away

On our stand it will be possible to view 2 Augmented Reality presses: ME hydraulic press and Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free admission ticket

To facilitate the visit and access safely, it is advisable to register to get the free admission ticket.

You can request it by simply filling out this form:

ForEMOst!

ForEMOst!

EMO is the worldwide exhibition of the machine tool, held in Italy and Germany, and that this year will take place in Milan at Fiera Milano Rho from the 4th to the 9th of October.

All the main international players of the manufacturing sector will take part in EMO MILANO 2021; so far there are more than 30 countries represented, covering all the segments that make up the world of the metalworking machines.

Undisputed leader in the trade fairs panorama, EMO represents the whole metalworking world in the best way, showing the best of vision and innovation.

Metal forming and metal cutting machine tools, robots, enabling technologies and automation, solutions for interconnected and digital factories, additive manufacturing will be among the key players of EMO MILANO 2021.

The exhibit is held in the entire Fieramilano Rho Exhibition centre, that can be easily reached with any transport means.

To guarantee visitors and exhibitors the participation in total safety in the exhibition, Fiera Milano Group has developed a Protocol for the safe conduct of trade fairs, in full compliance with the health rules and protocols issued at national level.

MECOLPRESS will participate with a “revolution” of the exhibition concept

Augmented Reality, the press just a click away

This technology allows to overlap multimedia information to the reality framed by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

A very powerful mean in the company communication field, and in this regard, the Augmented Reality has a strong impact on the customer experience, because it transforms the way in which companies interact with their customers.

In the trade fairs the Augmented Reality results to be very useful, both for the exhibitors and for the visitors who will be able to live a visual experience at 360-degrees.

Two will be the presses, chosen from the production range of MECOLPRESS, that will give birth to this innovative space of virtual reality, that will offer the possibility to see and to experience the functionalities of the represented machines.

We are waiting for you Hall 5 – Stand B29

Get your free admission ticket

To facilitate the visit and access safely, it is advisable to register to get the free admission ticket.

You can request it by simply filling out this form:

Biography of our hot forging blog

At the beginning of 2017 Mecolpress decided to start a blog entirely devoted to the hot forging world.

We set for it 2 goals:

- Being a reference point for hot forging companies, above all if these are first-time forgers.

- Supporting the companies having a long hot forging experience but that want to optimize their process, to better use their presses and to find answers to the necessities they meet step by step.

We have realized, doing some internet researches that it is very difficult to gather information regarding the hot forging world.

On Google you can find anything, but you will barely find suggestions or detailed deepening on hot forging!

Frequently we happen to be contacted by beginner hot forging companies, or companies having inexpert or not particularly qualified personnel (for example you can read this article) and all of these want to have further information.

We are aware that it is not possible to become expert forgers or to learn a job from Google but it is equally true that in 2020 I have to find answers on the internet to my necessities and some deepening on the topic.

Who are we?

Mecolpress is a company specialized in the production and installation of hot forging presses for brass, aluminum, copper, titanium, steel and other alloys.

Mecolpress was established in 1969, therefore we have a long forging experience and knowledge.

In our production workshop we have persons extremely expert in brass hot forging, and recently we have inserted in our staff also a steel “technologist”, we have available a mechanic and electronic technical office completely internal and a highly appreciated customer-care service.

To date we have developed and installed more than 1.950 presses at more than 400 customers all over the world, used for the forging of brass, aluminum, copper, titanium and steel.

One of the features that our customers usually appreciate most is the after sales service: the great and guaranteed material availability is added to the expertise and solid knowledge of the machines. The efficient feedback of Mecolpress lies in the largeness of the areas dedicated to the storage of parts that can be requested by the customers (we have 2 devoted warehouses) and in the investments decided exactly in favour of the “warehouse”.

Why writing a blog regarding hot forging?

At this point we said “why not sharing part of our skills online? For example, with a company from South Africa that is wondering if it’s worth it to convert his production in a hot forging system?”

“And in addition, could all the expert forgers (Mecolpress customer or not) be interested to understand if there are improvements to apply to their production? The world has changed and even fields such as the hot forging one may seem as more “static” but, as a matter of fact, they are not. If you don’t stay up to date you will lose important commissions and the quality of your work won’t evolve!

Which kind of answers will you find on this blog?

With our blog we offer ideas and tips to improve each forging process. To manage the machines and the forging lines in the best way in order to obtain the best productivity, more flexibility and less maintenance.

The topics that according to us are easier to speak on are the technical ones, thanks to the experience acquired in 50 years of activity and to our numbers, but we try to maintain a character that can be easily understood also to the less experienced companies, remaining at disposal for further in-depth detailed explanation.

In the “Case Study” category you will find for example:

- How we could help a German customer of ours to win successfully a challenge, to forge a very complex set of parts that he didn’t dare to accept as an order.

- Is it possible to reduce the gate valves costs by forging without flash? It is possible by means of ME hydraulic presses.

- Is your screw press driving you crazy? You could have disregarded what for you is just a detail, but our experience taught us that it can make the difference!

We propose solutions to problems caused by a not optimal usage of the presses or screw presses, by the inexperience; these are requests that we collect from our after-sales department. We give voice to necessities that also for expertised hot forging companies sometime can appear as complex.

A challenge we can win for our customer means for us a great satisfaction!

HOT FORGING PRESSES INTERVIEW WITH MECOLPRESS

Company manufacturing hot forging presses.

We report an interview of the digital magazine Easy Engineering of 28 April 2020.

Established in 1969, MECOLPRESS was founded as a manufacturing company of mechanical presses for brass components hot forging. Up to today, Mecolpress has developed and installed more than 1.950 presses, at over 400 customers all around the world, used for forging brass, aluminum, copper, titanium, steel. The current production site in Flero, in the highly productive area of Brescia, takes up a 30.000 square meters surface, 10.400 of them are covered and employees 55 people, reaching a turnover in 2018 of 11.5 million Euro.

In 2019, in occasion of EMO exhibition in Hannover, Mecolpress officially presented the new series of continuous and discontinuous cycle eccentric presses, the HEAVY series.

Easy Engineering: What are the main areas of activity of the company?

MECOLPRESS: At the beginning all efforts were concentrated on brass hot forging field; in the time, also through the acquisition of the historical brands Osterwalder and Dellavia in the screw presses section, the variety of machines that we design and produce is now so wide and complete to satisfy the most different requirements of the customers: for each specific material, shape and quantity to be forged, we are in the position to offer the most suitable solution.

Mecolpress is today the only company among the manufacturers of presses for the hot forging of brass, aluminum steel, copper, titanium, with a so complete production program.

Our present production program consists of:

- TDS: direct drive with electrical servomotor;

- Dellavia and Osterwalder: Traditional disc friction.

PG Knuckle joint presses

for calibration and coining of parts.

Presse Meccaniche Eccentriche

- SOV and SEO/F: for the vertical hot forging;

- SEO and HEAVY: for forging with horizontal cores, in single or continuous cycle.

for forging brass and aluminum parts without flash.

- PO: single station;

- S: multiple station, rotary table with hydraulic motor;

- E: multiple station, rotary table with electric motor.

In addition, Mecolpress is particularly active in after-sales service. The heart and pride of Mecolpress is its large spare parts warehouse, which is able to supply accessories or spare parts for machines produced fifty years ago. For this reason, in addition to the sale of machinery, there is a wide activity related to the service and supply of accessories (such as tools, arms, spare parts, etc..).

E.E: What’s the news for 2020 about new products?

MECOLPRESS: At the end of 2019 Mecolpress presented at EMO fair in Havvore a brand-new series of eccentric presses, named HEAVY, which defines a new standard for the hot forging of brass.

A machine concept that offer highest durability and reliability together with an innovative software system that allows the maximum control on the process and the a very easy operation.

E.E: What are the ranges of traded products?

MECOLPRESS: As a manufacturer with an own wide range of products, the additional equipment that we simply trade is limited to ancillary machines, to offer complete forging lines (delivering a finished part from the input of a raw material bar) to those customer that prefer to have a turn-key plant from one source.

Typical traded machines are: billets heating furnaces, forging dies, sand blasting machines.

E.E: At what stage is the market where you are currently active?

MECOLPRESS: Since our machines are dedicated to a very wide panorama of applications (from house building to automotive, from gas control to biomedical) there are always new developments in these sectors.

This is for us very stimulating because we are constantly involved in the design of new solution, to support our customers with the most suitable equipment to manufacture parts that are chancing in the shapes, in the alloys and in the technical requirements.

E.E: What can you tell us about market trends?

MECOLPRESS: In the past our customers were mainly subcontractors, producing many different kinds of parts for the most differentiated OEMs. We see now more and more companies that are interested in bringing back into their own activity the hot forging process, to have full control over the entire production line. And also, the subcontractors that still exists, are increasing in size, in capability, and in specialization: they are requested to be much more accurate, reliable, more flexible and fast in changing production and technologies.

For these reasons, the machines that both our customer types (the subcontractors and the OEMs) need, are machines that can easily switch from one application to the next, and that can record and control really in depth every aspect of the production process. The user is therefore becoming more an engineer, that study and program the process in advance and then let the machine run autonomously, instead of an operator that has to stay full time at the machine, checking and adjusting the settings.

E.E: What are the most innovative products marketed?

MECOLPRESS: As above indicated, one of the most innovative products that we offer today is the new range of Heavy presses.

In parallel to this, we are widening the offer for the ME hydraulic presses which are designed to forge net shape parts. These machines are extremely versatile, can communicate in two directions with the company ERP software to exchange production data, recipes, preventive maintenance information. And are also able to automatically detect a non-conforming product and separate it from the good ones. This makes the ME forging presses a fully automatic system, that does not require operators to work but also does not need regular presence of quality control staff to check periodically the output.

E.E: What estimations do you have for 2020?

MECOLPRESS: At the end of 2019 we planned a very aggressive budget of sales for the 2020, and supported it with several activities and strategies, from the participation to many international shows, to the production of machines for stock, to grant to our customer very fast deliveries.

Unfortunately, due to the Covid-19 virus spreading, many commercial activities had to be reprogrammed or postponed. We are now investigating the world markets to assess what will be the customers’ propensity to invest for the remaining months of this year. We are very optimistic that we will in any case be able to reach most of our targets also thank to the availability of machines in our workshop, which is allowing us to complete deliveries in this year of machines ordered in the second and third quarter.