If the forging industrial process is stable and steady, it generates profit!

If the forging industrial process is stable and steady, it generates profit!

Today more than ever it is very important that the industrial process, in our case the hot forging one, remains stable and steady during operations time. As a matter of fact, by achieving this goal it is possible to generate profit.

The costs increase in raw materials, energy and specialized personnel is a more and more important and relevant constant for every manufacturing business. The profit of each order or job must always deal with these variables which can hardly be controlled.

The production stability can be controlled: the process must always be repeatable in the performances and must grant steady operative costs.

The metals hot forging is not an exception. Annual productions can reach tens of millions of pieces and each of these must be produced following the expected and planned parameters, the profit expectation must be guaranteed!

How is it possible to manage, monitor and correct tens of parameters, for millions of parts, granting the stability?

It is possible to grant the process stability even when millions of parts are produced and the process parameters are numerous, in this way:

01

=> monitoring the variability factors that influence each process to understand if they are under control or not by means of the statistical control.

02

=> Obtaining highest rigidities, forging force, and positioning precision.

03

=> Real time check of the behaviour of the main process parameters.

04

=> Modification of the main forging values without interrupting the production.

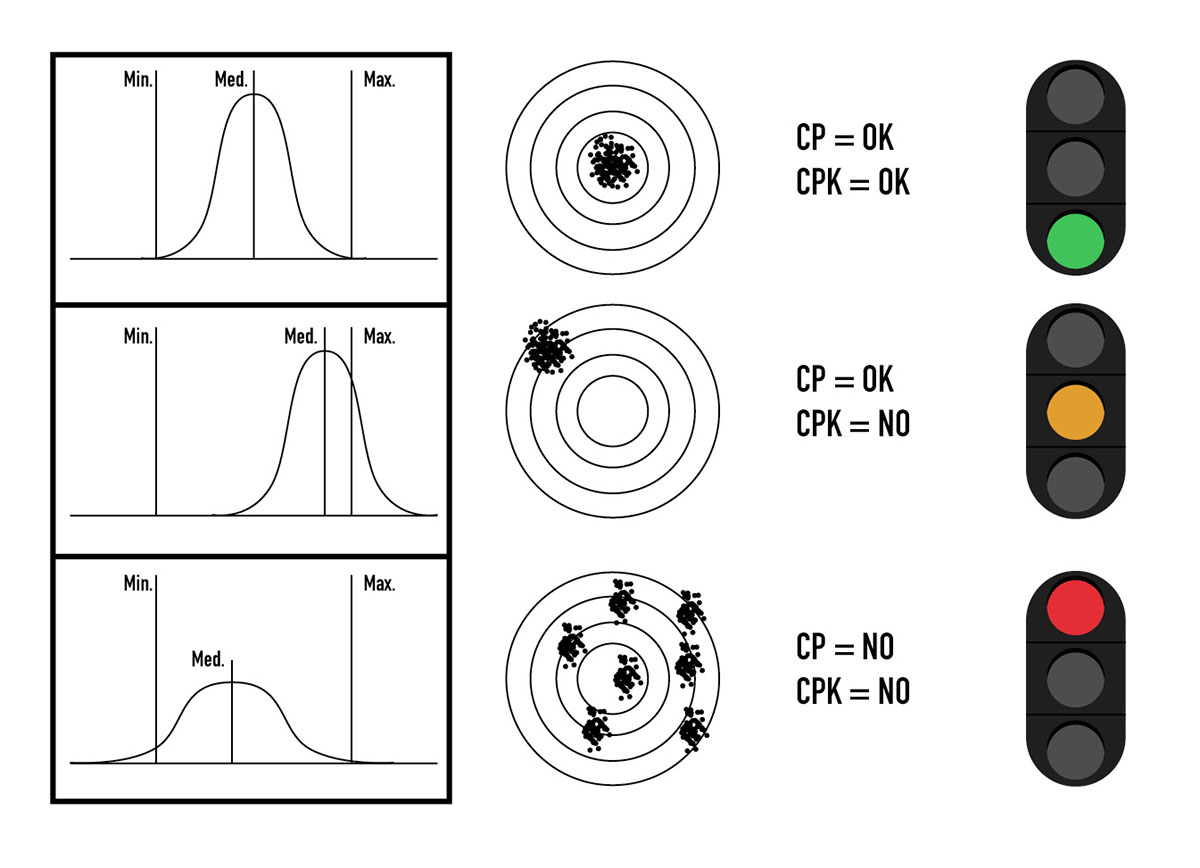

Statistics teaches that Cp and Cpk parameters are fundamental for controlling the progress of the forging process, for each variable in fact they are the key to understand its stability.

The example of the shooting with darts game allows you to quickly understand the concept:

a good Cp indicates that we are very repeatable in our shots, but it does not mean that we are hitting the target.

Only by obtaining a good Cpk, too, as a matter of fact, the optimal result is guaranteed!

=> Cp e Cpk must be much higher than one.

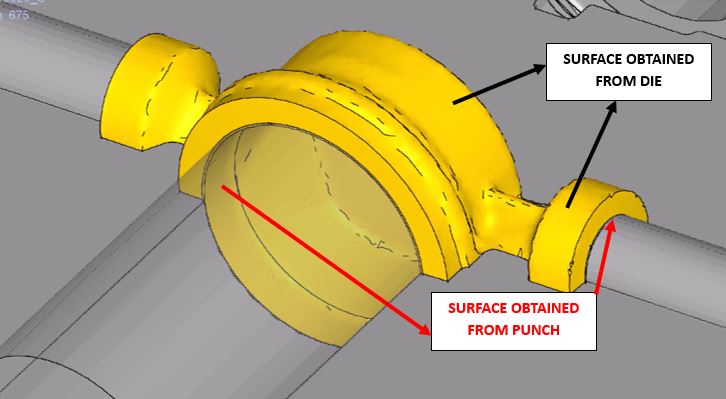

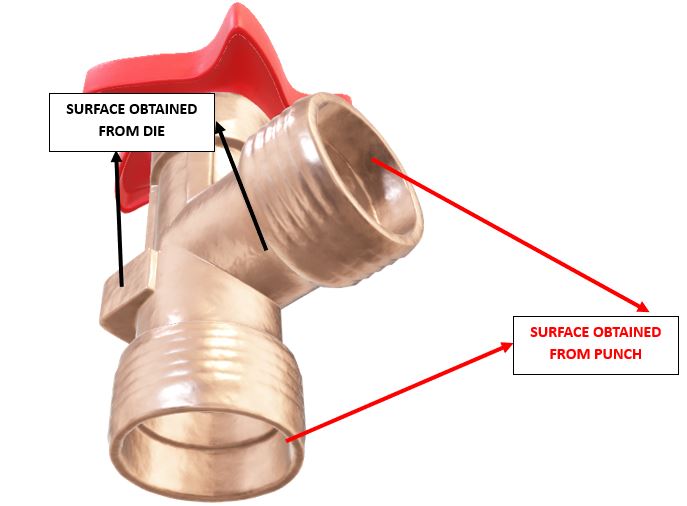

Let’s move on to a practical forging example:

-

Forging a batch of 25,000 water meters.

-

or forging a batch of 50,000 gas control valves

The dimensions of the forged parts are determined:

- by the surfaces of the part shape created in the die.

Cp depends on the presses rigidity performance and on the die design.

Cpk depends on the correct evaluation of the material shrinkage, which is related to the forging temperatures, to the part geometry and raw material chemical composition.

- by the punches involved in the material deformation.

Cp is obtained from punches rigidity and thrust force.

Cpk is obtained from the possibility to adjust the punch arrival position.

During the forging tests carried out with our customers from all over the world, the dimensional statistical analyses carried out on the produced samples (batches of thousands of pieces) have demonstrated that Cp and Cpk parameters were always abundantly and stably higher than one.

The complex geometries or the parts dimensions are not a problem.

How could we maintain the forging industrial process stable on our ME Hydraulic Presses?

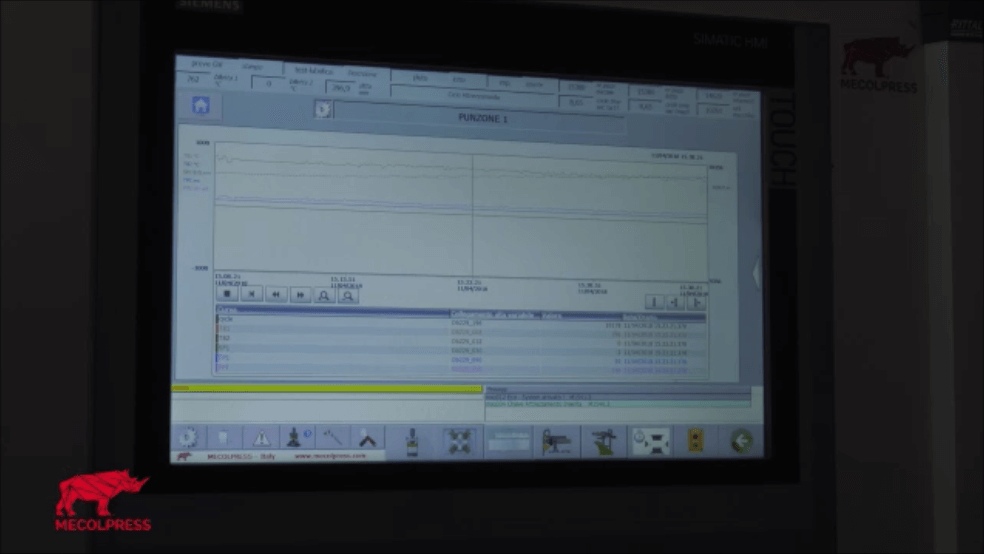

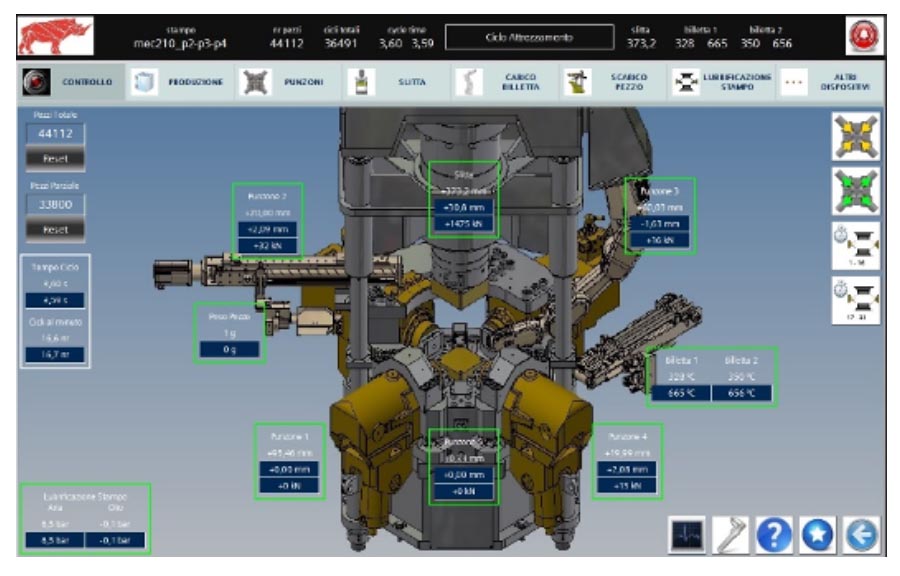

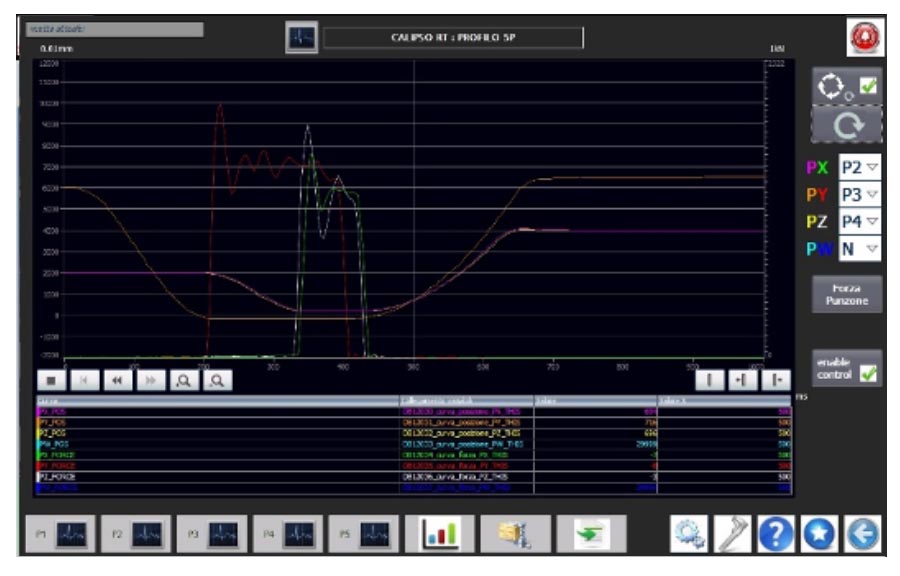

- Mecolpress presses are equipped with Calipso software for operative parameters setting and their continuous control. Calipso, software entirely developed by Mecolpress, allows you to control the main process parameters in real time (forging forces, position, speed, …). Even before measuring the pieces, it is possible to understand if the forging process is stable and guarantees constant performance.

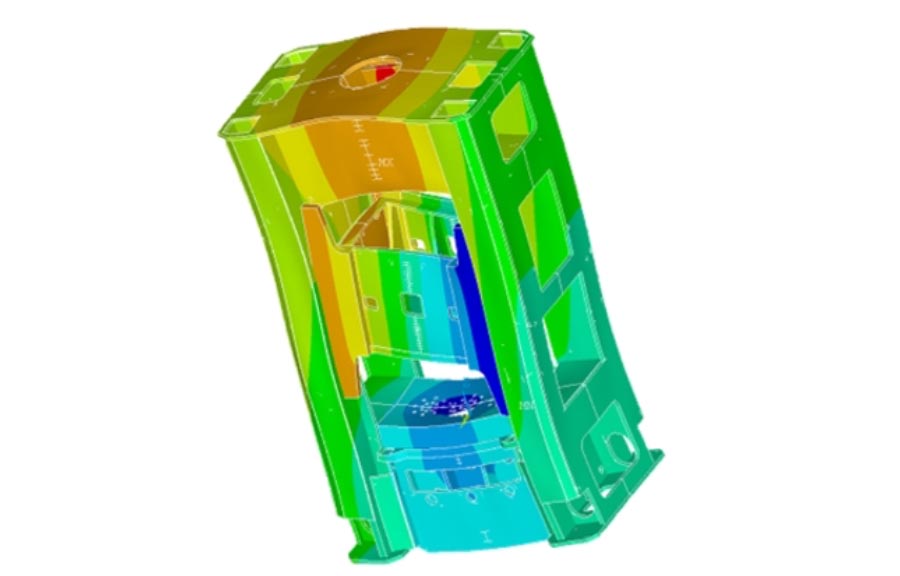

- Our presses are designed with advanced calculation systems (FEM) which allow to predict the rigidity of the components with the utmost precision, minimizing their deformations, even if subjected to high loads.

=> Cp under control

- We have designed our hot forging presses in order to have the highest possible dies closing force and maximum punch thrust force.

=> Cp under control

- The stroke adjustment of the individual punches occurs in real time, thus allowing the related dimensions to be modified during production.

=> Cp under control

- The long experience in dies design and the collaboration with the best specialized companies in the sector have allowed us to create the dies with extreme accuracy, in order to guarantee stable production of the pieces.

=> Cp under control

Reduced energy consumptions with the new hydraulic ME presses

The new Mecolpress ME hydraulic presses grant reduced energy consumptions.

How did we get to achieve this goal?

Mecolpress has been working with its customers for more than 50 years providing the best forging technologies that allow to maximize the quality of the products and the related productivity.

The forging process improvement needs do not always seem to proceed in the same direction:

- the energy consumption reduction requires the reduction of the installed power;

- the high productivity and the raw material reduction require increasing installed powers.

Our customers and partners are dealing with this conflict and are wondering how to come out as winners.

“Which is the most abundant existing source of energy? the least polluting, least expensive, most immediately available one: that is, energy saving …”

Piero Angela

What does Mecolpress propose to grant in the same page reduced energy consumptions and high productivity?

Mecolpress is not afraid of challenges, indeed it knows that these represent an opportunity to grow and improve.

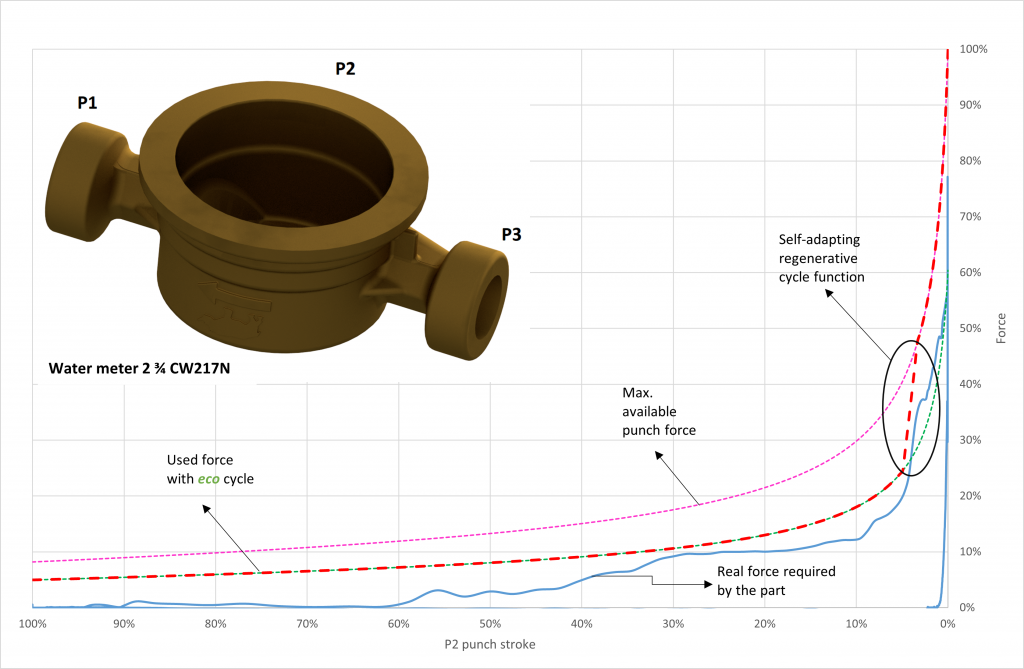

Thanks to the continuous and accurate control system, Mecolpress presses determine and memorize the process parameters at every fraction of a second, i.e. the minimum force and speed requirements to obtain a certain product with the best characteristics. Under these values it is not possible to obtain an acceptable product.

Our long experience has allowed us to evaluate numerous forging cases, from small connectors of ½” up to large valves/water meters of more than 2”, in standard and lead-free brass grades.

To reduce power when it is not needed and to maximize it when it is needed! This is the secret.

The forging process control system

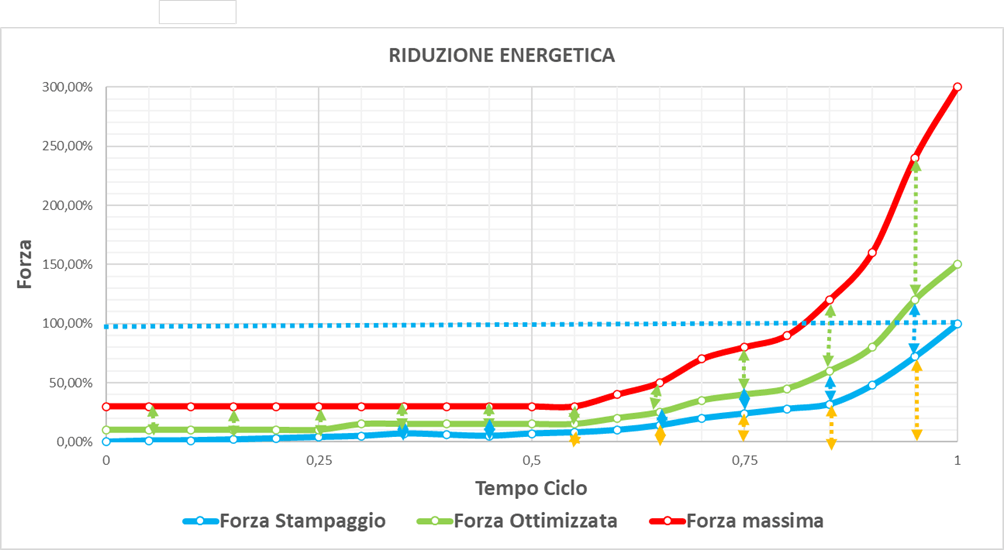

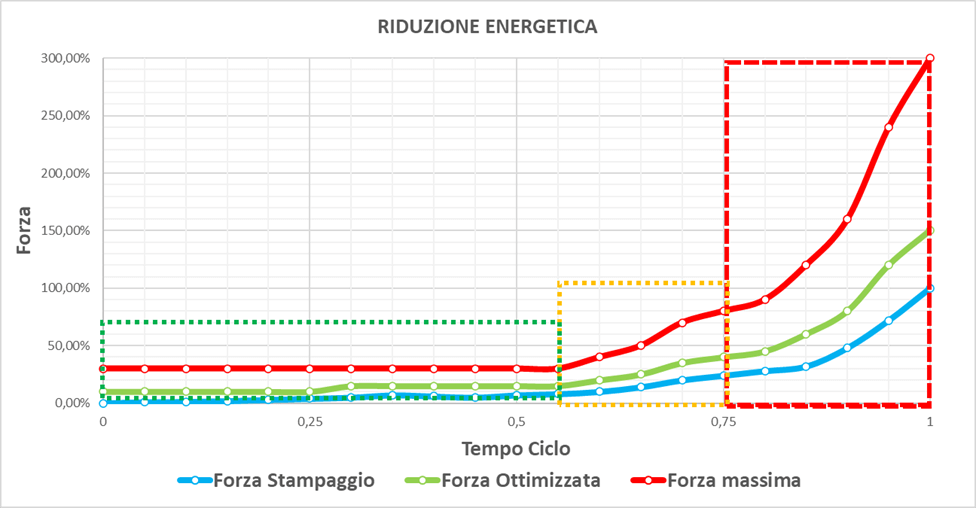

The press control system learns (ADAPTIVE CYCLE) the trend of the forging cycle and regulates the pressure and the flow of the oil (REGENERATIVE CYCLE) in order to get as close as possible to the minimum forging force. A reasonable safety margin is maintained in order to compensate for eventual external parameters variation (billet temperature, material quality, dimensional tolerances, …).

During the forging cycle Mecolpress press will have three phases: power reduction, transition, maximum power.

We monitored the flash-free forging process of the body of a 1 1/4″ ball valve with a productivity of 12 pieces per minute, therefore 720 pieces per hour.

Thanks to the ADAPTIVE-REGENERATIVE cycle the energy consumption is reduced by 50%, reaching an average consumption of 45kWh.

But let’s not forget the other advantages acquired:

- production capacity more than doubled compared to the traditional cycle,

- high repeatability of the piece quality (cp>2),

- constant compliance (cpk>1.33) with very tight dimensional tolerances (± 0.1),

- minimized material consumption thanks to over 6% flash-free forging,

- improved workability thanks to a more uniform internal conformation,

- increased product quality thanks to the elimination of internal defects.

ME 350 NEXT GENERATION PRESS

ME 350 Next Generation Press: still the most powerful press, now it also minimizes the energy consumption.

ME350 press is the powerful of Mecolpress hydraulic presses: the latest version we have developed is able to grant a significant reduction in energy consumption.

Our goal is to make our customers more competitive in a very challenging market. The increase in the costs of raw materials and energy is not yet stabilized and a substantial reduction is not yet in sight. Our customers have to manage and deal with variables such as:

- product differentiation,

- the need to adapt to high volume production batches,

- managing frequent product changes,

- the difficulty of finding a stable workforce,

- the need to produce just in time,

- the increasingly high quality required of the forged product.

Mecolpress technological innovation starts from the challenges the market imposes on producers with the aim of overcoming them.

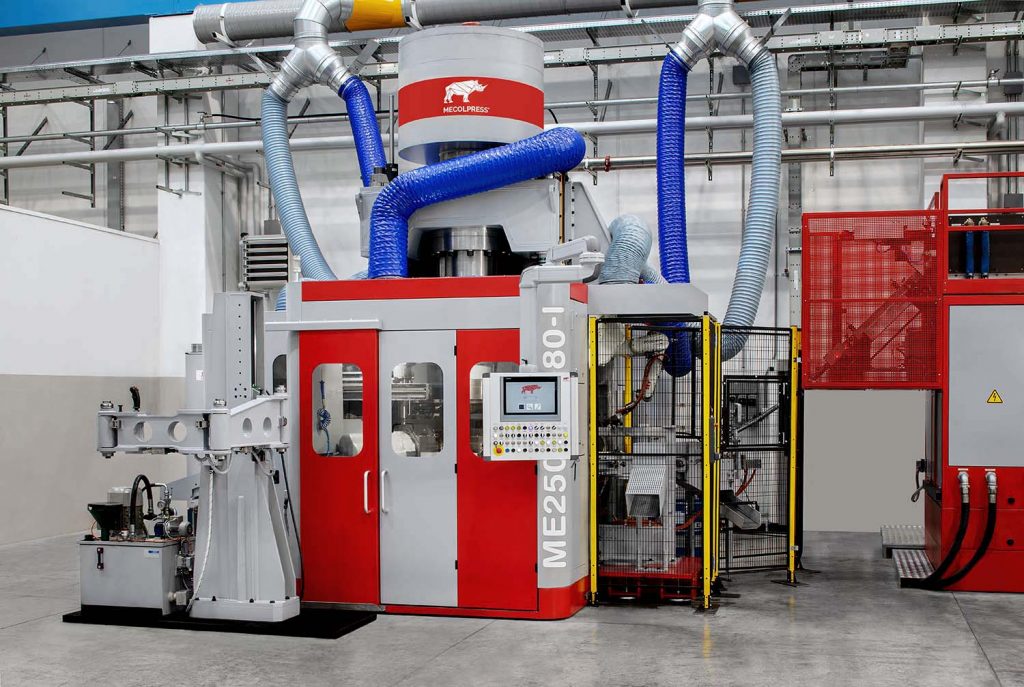

The new ME350 Next Generation press incorporates all the latest innovations:

01

Maximum dies closing force and maximum one of the independent extruder punches => flash-free forging and reduced thicknesses => reduction in raw material consumption (up to 40% compared to traditional forging).

02

Regenerative hydraulic circuit and adaptive power control to harmonize the energy consumption with the effective forging demand => reduction of electricity consumption (up to 50% compared to the presses of previous generation).

03

Anthropomorphic loading robot and quick dies changing system => increased flexibility by changing a product with another, reducing the necessary machine downtime.

04

Possibility of forging more parts each cycle in the shortest time, reaching the production of 5,000 pieces per hour => high-volume production batches are completed in a short time.

05

The production process is fully automated and connected to existing MES\ERP systems (Industry 4.0) => better staff management who can easily manage multiple presses simultaneously without stress.

06

CALIPSO Software checks the trend of the forging parameters (forces, displacements, sequences, ..) by comparing them with the references => any possible criticality on the quality of the product is overlined in real time and the part is separated from the correct ones.

All these innovations are added to Mecolpress long-lasting experience in the forging field, gained in the province of Brescia, a key area in the global panorama of the production of brass components. Mecolpress offers to the customers a vast availability of spare parts to minimize the relative delivery times and a team of specialized technicians to carry out assistance interventions all over the world.

A CUSTOMIZED TECHNOLOGY FOR THE PRESSES

Courtesy of Publitec

Magazine Deformazione N.281 FEBRURY 2023

of Aldo Biasotto

Mecolpress has chosen to make use of the customized solution proposed by Siemens, SIMAHYD, to ensure high reliability and better control of the forging process. This solution is combined with Simatic controllers, allowing both control of the hydraulic valves and management of the variable speed pumps.

Mecolpress is a company specialized in the production of machines and systems for hot forging.

Its story begins in 1969 in the Brescia area: here, for over fifty years, the company has been innovating and developing ever new solution to remain competitive on the worldwide market. The heart of Mecolpress beats in Flero (Brescia) where the technologies are designed and manufactured in an industrial area of 30,000 square metres, 10,000 of which are covered by buildings. With a staff of around 60 people, to date Mecolpress has distributed around 2,000 presses to customers in 60 countries all over the world. The context in which the company operates is broad and differentiated . At the beginning it was only focused in the brass hot forging applications, in particular in the production of fittings, valves and fashion products.

Later on, it was expanded to the world of steel, aluminium and special alloys applications, both hot and cold, thus embracing further sectors: automotive, industrial, medical, sports up to watches. To remain competitive on a global scale and bring an innovative contribution to the metal forging market, where the scenarios for the future are increasingly challenging, Mecolpress needed to rely on a top-level partner for technological components.

Thus was born the collaboration with Siemens, in particular regarding the electrical and electronic supply to the company. The goals: to ensure a high reliability in the presses functioning and better control of the forging process.

The way to reach these goals: SIMAHYD. “Siemens offers new solutions regarding power and process control, on a large scale and for different applications. To be successful, you need to be innovative in making your customer competitive: the synergy between Mecolpress and Siemens allows to reach this goal” says Maurizio Razio, Electrical Engineering Manager of Mecolpress.

The advantages of an open and customized package

To pursue this goal, Mecolpress therefore made use of the customized SIMAHYD solution. It is about a custom-built application package, specifically designed for Simatic S7-1500 controllers, which allows the control of hydraulic axes thanks to software modules that extend the functionalities of the original technological objects in Siemens controllers. In this way, both a control of the hydraulic valves and a management of the variable speed pumps are obtained.

The high level of flexibility of applications in the hydraulic sector facilitates a quick and simple control implementation: this was the case of Mecolpress technologies. By applying this solution to the presses, thanks to this package it was possible to ensure the control of the proportional valves on which the seven hydraulic cylinders depend. “The advantages of SIMAHYD open package are many: it allows to make the modifications necessary for integration into the hydraulic circuits of the machines, preserving the existing control program and, to facilitate the axes set-up, it also includes the display part, also It can be integrated into the existing operator interface.

Furthermore, this application is characterized by controller type “fail-safe”, which facilitates an integrated management of the entire machine safety”, explains Sergio Mazzon, OEM Business Developer of Siemens Digital Industries in Italy. Thanks to this customized solution, it was therefore possible to quickly manage the hydraulic power axes, such as those present on the ME Next Generation series presses, reaching extremely high precision and repeatability.

A technologies portfolio for each customer

Today Mecolpress can offer a complete portfolio of technologies according to the application needs of the Customers: eccentric mechanical or screw presses, hydraulic presses, auxiliary presses. The benefits are many and related to both the presses and the complete forging lines: high production capacity with reduced cycle times; high efficiency thanks to the minimization of energy, raw and semi-finished material consumptions; product quality control by monitoring process parameters; complete automation of the production cycle thanks to the reduced intervention of the operator; technologies allowing quick tooling change between one product and another one, in order to manage small production batches too; compatibility with industry 4.0 and arrangement for predictive analysis systems for maintenance and processes; remote or in person assistance service and spare parts warehouse suitable for a prompt response in case of need.

Thanks to the experience gained and the particular attention to innovation, today Mecolpress is able to face the growing challenges of the market head-on. “Thanks to a reliable partner like Siemens, our technologies are perceived as improving and taken into consideration for investments in new industrial assets. The prospects for growth in turnover and market share are solid and demonstrated by the numbers of the last two years and by the orders portfolio acquired” says Danilo Fagnani, Sales Manager of Mecolpress.

Brass hot forging: from the mechanical technology to the hydraulic one with me series presses

Metals hot forging is a reliable and repeatable process which allows to obtain components with high mechanical properties, minimizing the raw materials consumption.

Over more than 50 years Mecolpress has been at the service of its Customers, providing the best forging technologies that allow to maximize the products quality and the related productivity.

Not always changing means improvement, but to improve you need to change

Mecolpress is committed every day to sharing experiences with its partners to follow a common path with the aim of overcoming the performance limits of existing production processes.

It is not the strongest of the species that survives, nor the most intelligent one, but the most responsive one to changes.

Exclusively from the merge of the complementary activities:

- Development of innovative technologies;

- From consolidated experience in the hot forged parts production, the way for barriers overcoming in the productive processes can be born;

- Increase of production capacity;

- Improvement of product quality;

- Reduction of raw material consumption;

- Reduction of energy consumption;

- Reduction of resources consumption (lubricants, cooling water,…).

The experience shown in this article is related to the brass hot forging

and more precisely to the passage from the mechanical to the hydraulic technology (Mecolpress ME Series). The product subject of the evaluation is the body of a sphere valve with dimension 1” and ½. Even if it may seem a standard and consolidated product, each customer has his own design and specific features.

Mecolpress has collaborated with an Italian industry-leader company to the production of the new die and to its industrialization. After two working days and proactive information sharing, by using our ME hydraulic press, we have reached:

- Production capacity more than doubled;

- Material consumption minimized of about 6.5% thanks to the flashfree forging;

- Improvement of the workability thanks to a more uniform internal conformation;

- Increase of product quality thanks to internal defects removal.

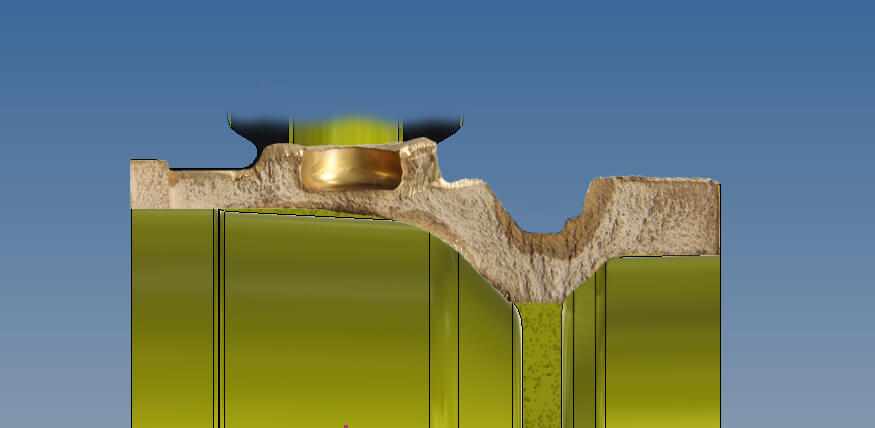

Even if at first sight a forged part may seem perfect, its integrity can be granted only from the internal analysis.

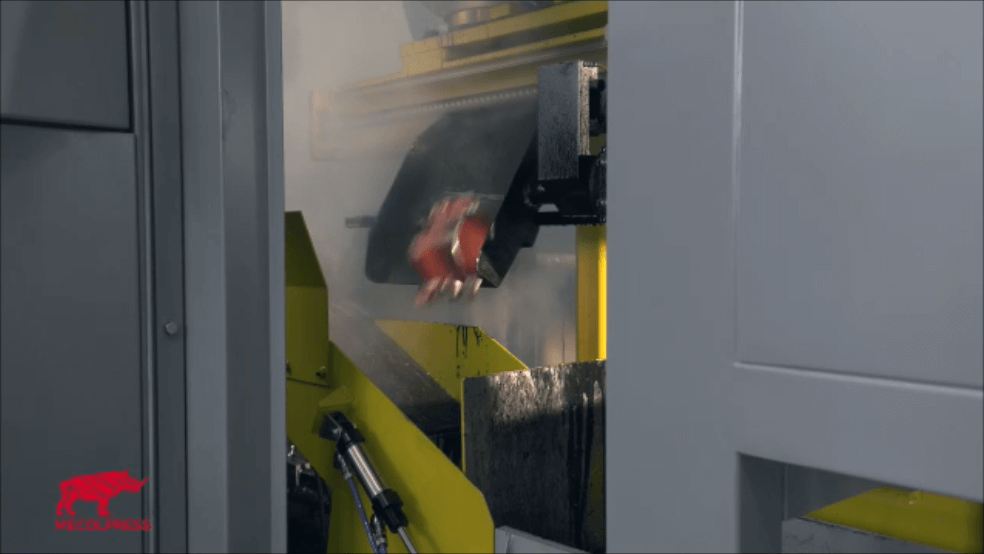

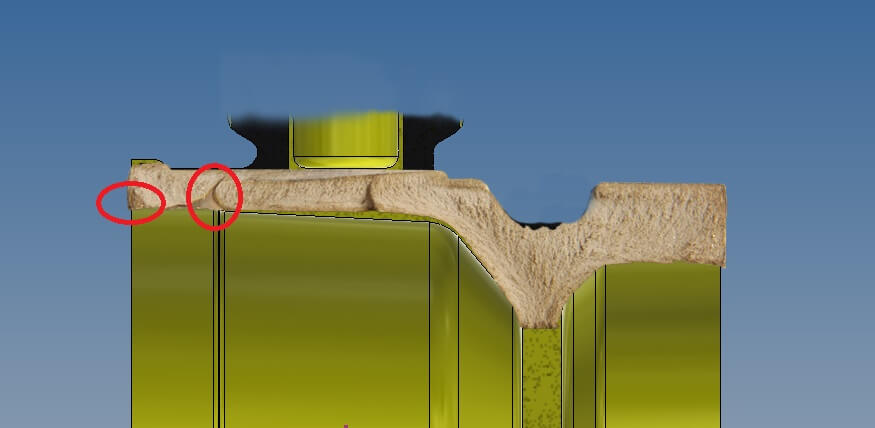

The material flow is unbalanced, the flowing speeds are not uniform, the material tends to detach from the die and to fill some areas before others (picture 1). When the flows meet each other again, they have such temperatures that they cannot be properly welded. The cold welding, indicated by the red circle, can cause problems during the machining phase, if it is included, even partially, in the surplus metal, or if during the assembly phase when the tightening torque of the front nut mechanically stresses the defected side.

Mecolpress hydraulic presses of ME Series, even without any previous simulation numerical analysis, allow to set the correct sequence of part forming according to the material flow dynamics.

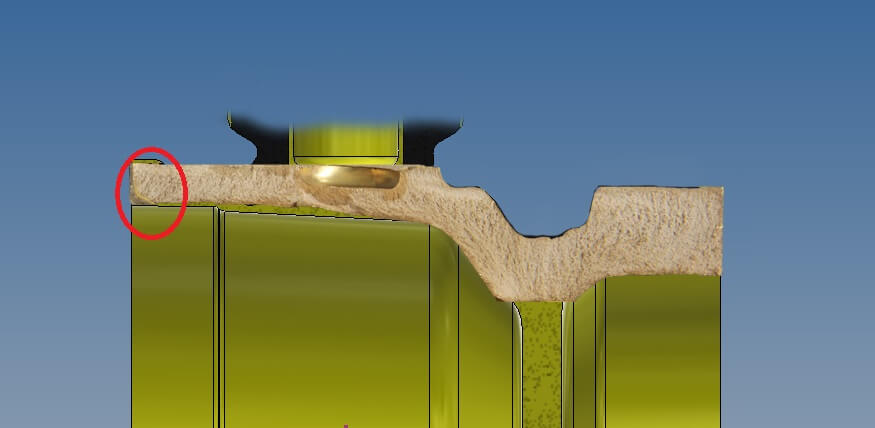

Thanks to this precious pre-forming function a progressive modification of the penetrations of the 3 punches has been applied and this has leaded to the desired result: the repositioning of the defect in a marginal zone (picture 2).

Then simple modifications to punches shape were taken into consideration in order to totally eliminate the cold junction (picture 3).

Two really efficient working days, product industrialization with new dies and more than 5500 good parts in the boxes, ready for the machining tests! A thank goes to our Customer for the precious collaboration, a thank to our team for the availability and speed of action and a thank to our hydraulic ME press that tirelessly, once again, allows to overcome the production limits and to permit a great improvement!

Wait!!! And what about energetic consumptions?!?! We are collecting data… a little patience… in the next article you will be informed about everything!

HYDRAULIC PRESS, Mecolpress leap into a new eco-green modality

Main features of the new ME eco-green Hydraulic Press

Mecolpress S.p.a. is glad to introduce the new improved features of ME family hydraulic presses, born from the need to offer to the Customers a more flexible and performing machine in terms of product quality and energetic consumptions.

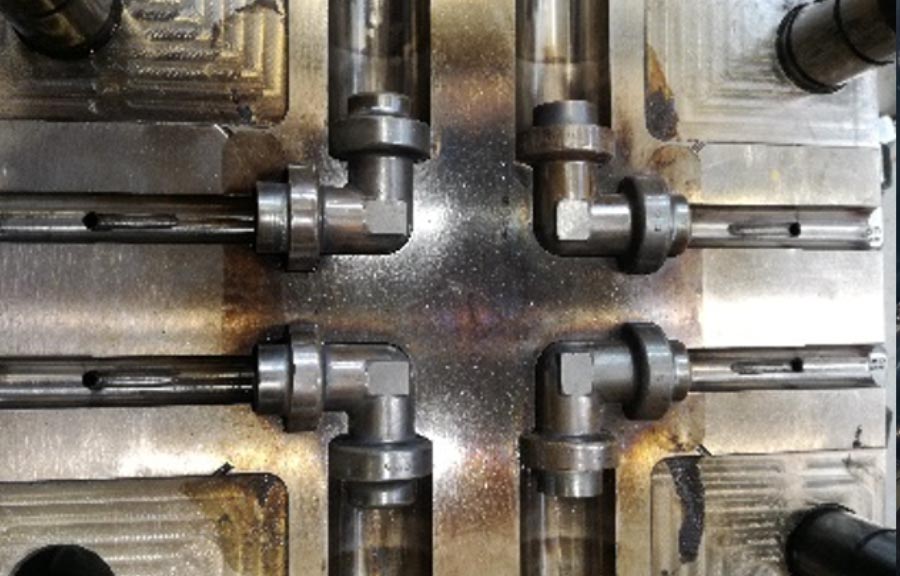

We are currently proposing the family of ME presses having the die closure force that is in the range from 100 to 500 tons (as standard equipment) and with a minimum side punches force of 30 tons that can achieve up to 350 tons. Each of these last ones has completely independent operation, adjustable speed and set-able movement phases (forward-stop-backward); depending by the type of part to be forged , the hydraulic closure cylinder allows to apply the necessary forging force also before the dies contact.

The new presses can be fed by one anthropomorphic robot for the billets loading and one synchronized unloading arm for the forged products that eliminate the set up difficulties of the traditional past technologies; regarding the fumes suction, after a careful analysis of the actual state of the art, we have implemented and optimized the system making it more functional and effective.

The fume suction hood collects the emission very close to the sourcing point decreasing any possible spread into the press cabin, granting to the operators the best inside view of the process and reducing the oil collection and its possible overflow.

In this regard, the machines of the new series are integrated with the walkable grids that surround the press and prevents the eventual drip on the floor of the working area.

The hydraulic presses can be supplied customized with optional equipment according to the production needs.

For example, one of the punches can be oriented with the coring angle that is different from the classic 90° configuration , allowing in this way the realization of particularly complex shapes, like y-joint or filter body.

Other possible configurations are of new ME eco-green Hydraulic Press are:

- the addition of a fifth vertical punch acting from under the die,

- the loading of one or two billets at the same time up to a maximum of four,

- the addition of a dies-holder arm lightening the machine tooling process,

- the addition of a quick dies changing system with hydraulic locking,

- the addition of an induction dies heating system which the machine is particularly compatible with,

- fire extinguishing system integrable with the machine.

Moreover the main innovation is related to the energy saving achievements if compared to the previous series.

From 2022 all the ME presses can minimize autonomously the energy amount that is needed to produce the desired forged part: the press learns automatically the optimal pressure to be addressed to each forging punch: ECO cycle (settable from the control panel). Furthermore, during the movement of each forging punch, Calipso control software optimizes the time in which it is necessary to switch to the maximum achievable pressure (regenerative self-adapting cycle function): all the press parameters will be consequently harmonized according to this requirement.

This behavior represents the key economic and competitive advantage for the press user that can save up to 50% of the total installed energy without losing or reducing the punches force and can optimize the forging process parameters in order to minimize the energetic consumptions. To do this the operator direct intervention is no longer necessary. The operator is not required to have a long term experience or particular skills : he will simply have to activate the ECO cycle from the control panel, ME press will care of the rest!

he will simply have to activate the ECO cycle from the control panel, ME press will care of the rest!

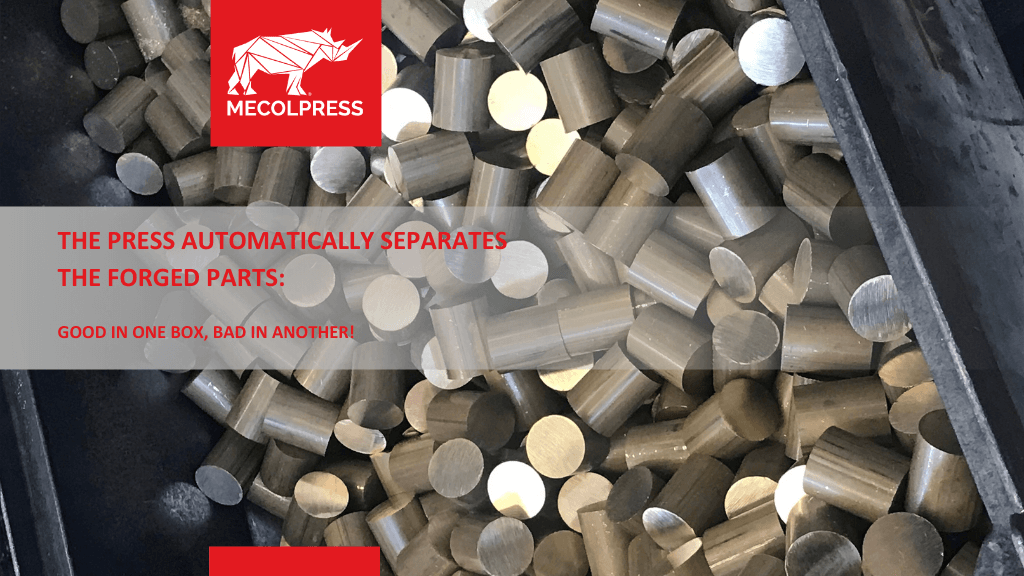

THE PRESS AUTOMATICALLY SEPARATES THE FORGED PARTS: GOOD IN ONE BOX, BAD IN ANOTHER!

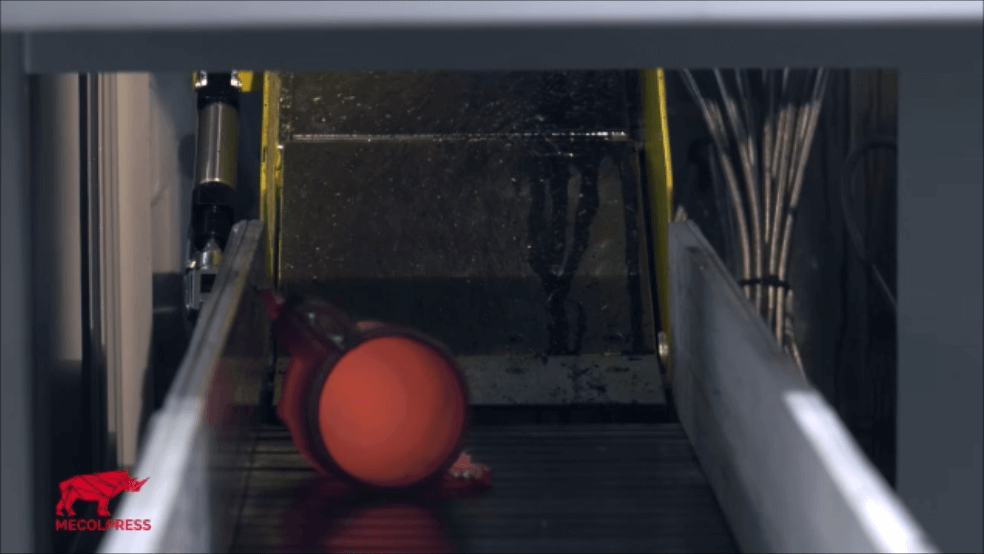

Differentiated unloading of the forged pieces

The press automatically separates the forged parts and divide them into different boxes. The press has become intelligent!

The differentiated unloading of the forged parts is an interesting function that Mecolpress provides by default on all hydraulic presses, but it can also be added as an option on eccentric mechanical presses.

Hot forging for higher quality of forged parts

The metal hot forging differs from the cold one because it allows you to obtain high quality pieces through an important deformation of the starting material. By working brass, copper, titanium, steel and aluminium by means of hot forging presses, in fact, it is possible to produce particular shapes, even with complex geometries.

The metal hot forging therefore allows to obtain parts that are more resistant than those obtained through other production processes.

In particular, metal hot forging can increase the strength and resistance of the products. For these reasons, the production of hot forged pieces guarantees specific advantages in their mechanical characteristics compared to those produced with other technologies such as casting or mechanical machining with chip removal.

The hot forging, compared to the casting processes, allows to obtain mechanical characteristics and surface appearance of superior quality. We at Mecolpress know it well, so much that we have made “Technology of Shape” our motto.

The piece produced must therefore be perfect, its quality must be certified. For this reason, Mecolpress has designed a system that allows the press automatically separates the perfect forged parts from those to be evaluated as they may not be such.

Why is it so important that the press separates the perfect forged parts from those to be evaluated?

From the automotive sector, the Lean production method teach us:

- Companies can be competitive on small production batches (producing only what is necessary) instead of manufacturing high quantities at low prices, with the risk of keeping high stock levels, are rewarded with success.

- The second must of the “Lean” work methodology is the zeroing of the waste and dispersions, or in other words, of the useless productions because of defected parts.

One of the most recurring needs in our customers is to have an ever more intense control of the forging process: the machine must be able to control as many parameters as possible important for the forging process, record them to make statistical predictions on the deviation from the optimal production, carry out checks.

Mecolpress offers a series of forging presses that fully meet the needs described above: the ME hydraulic series.

The hydraulic presses can control numerous process parameters and on these manage the logic for rejects or collect the measured values for statistical analysis. For example, they can control:

- the temperature of the billets to be loaded,

- the coring punches penetration time,

- the punches real penetration force,

- the final position reached by each punch.

Here you can learn more about the most important process parameters that hydraulic presses are able to evaluate.

The machines of the ME series have the credentials to be competitive in a modern and controlled forging field; they operate at their best on medium / small batches, thanks to their flexibility.

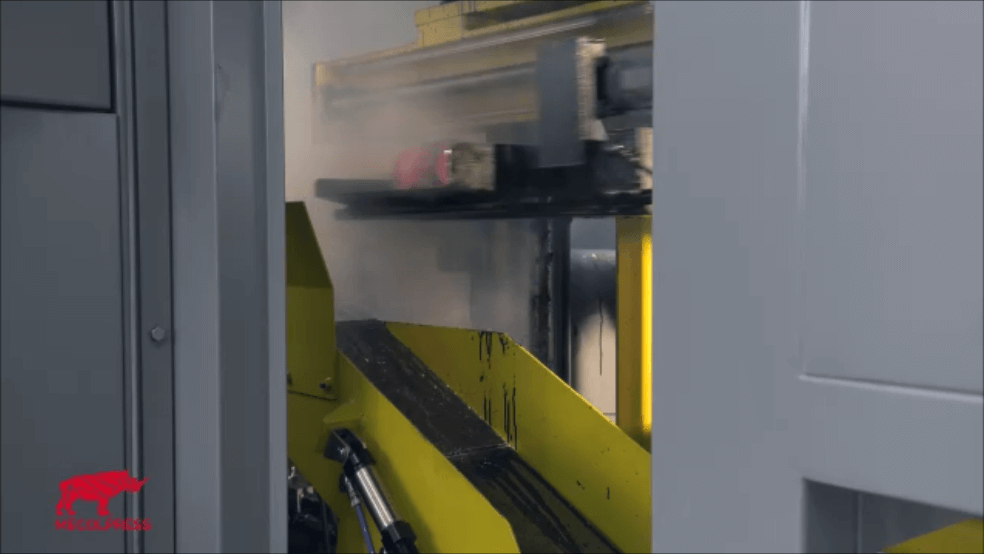

In this video we show how our hydraulic presses perform the differentiated unloading of the forged parts:

The pieces that do not fully comply with the process parameters set by the operator and analysed by our powerful Calipso software to control the forging process, are unloaded in a separate bin.

For the customer this operation translates into an important saving method:

- Less waste of time,

- Less material / pieces to be discarded,

- Be sure that the forged piece complies with the required characteristics,

- Get perfect shapes.

Another company based in Brescia chooses Mecolpress hydraulic presses.

With regularity and continuity, Mecolpress gains new Italian customers, the hydraulic press is confirming to be the winning choice.

Case Study: How we acquired the latest customer from Brescia

We report the case of a new customer based in Brescia that we have just acquired, an interesting case study to understand which are the necessities of the companies working in the hot forging sector and how Mecolpress provides answers.

It is the case of a company established in the international market for the very high quality of its production, consisting mainly of mini valves, valves and fittings for the sanitary and heating sector. This company has its own brass hot forging department, developed to cover the 100% of the forged parts needs; the recourse to very few and highly selected external suppliers happens just in case of particular peak of volumes.

The presses equipment of this company consists of 5 machines, always full of work: 3 more traditional and “dated” (eccentric mechanical presses of the historic producer Rovetta, that now no longer exists) and two more recent little hydraulic presses of a particular type, proposed by an European producer.

Knowing better the company, now customer of us, we could appreciate right from the beginning some undisputed features:

- Advanced transfer machines;

- A working method focused on the precise and deep knowledge of all the productive processes;

- A forward-looking vision on the continuous training of all the personnel that is involved with the management regarding the strategic decisions and that creates a uniform a close-knit group;

- A quality department having knowledge, methodologies and instruments not only for the examination of the parts but also for the evaluation of the method used for their production.

During various meeting both at customer’s and Mecolpress site, we had the opportunity to present them our complete range of presses and in particular the functionalities of our hydraulic presses of ME series.

Mecolpress method

The customer wanted to test us, taking advantage of the Mecolpress strategy of having a selection of presses almost ready for delivery, for carrying out forging simulations with two parts of their production range on the specific press of their interest.

The result was that, thanks to the constructive collaboration of both teams (the customer and the Mecolpress ones), in just 9 weeks from the decision of beginning with the simulations, we could:

- Carry out the forging simulations of the two parts to be tested;

- Manufacture the related forging dies;

- Carry out forging tests with two dies (in manual and in automatic cycle, since Mecolpress has 2 high-performing push-type gas furnaces;

- Dismantle and demolish one of the old presses of the Customer;

- Deliver at customer site in Brescia a new ME150/4G62 hydraulic press, exactly the same one the customer saw and tried.

Why the company under consideration chose Mecolpress?

We thank the customer for the trust and for having tested us, and we are particularly proud that even they, as other customers, after having bought and used the hydraulic presses of our competitors, have chosen to purchase Mecolpress for the future.

The decisive points for this new positive result are in short:

- Mecolpress can offer to the customer not only any kind of new presses, but also exceptional expertise in the maintenance of old presses, of other manufacturers (in this case Rovetta).

- Mecolpress hydraulic presses, both for mechanical and construction project and for extremely developed software, offer to the user an incomparable ease and usage flexibility.

- Choosing Mecolpress, the possibility to conclude an investment in very short time, and to see it becoming rapidly productive; who wants to invest has no time to wait and must be helped to be competitive as soon as possible!

Would you too like to try a forging simulation?

Don’t waste your time,

test us!

Hydraulic Press ME100, the SuperFast!

Forge up to 60 pieces per minute without flash!

Our range of hot forging hydraulic presses ME has been enriched with the latest model ME100. It is a compact machine, dedicated to the forging of low-weight complex pieces, with extremely high productivity.

Mecolpress patented hydraulic presses, suitable for hot forging of standard and special brass or aluminium pieces.

This clamping force is higher than those of traditional mechanical presses. Independent & controlled movements of the ram and punches allow for flash-less hot forging also of complex pieces.

In addition to the ME150, ME250, ME350, we now also offer the ME100:

- 100 Tons of die closing force;

- 30 Tons for each of the punches (there can be up to 5)

- Forge in single or double figure, horizontally or vertically, and it is Super-Fast!

We tested it up to 30 strokes per minute and of course … it was promoted with full score!

As for all our ME hydraulic presses, the range of pieces that can be forged is very wide.

Here is a photo of typical brass parts that can be forged with this press:

Some info as an example:

– it can print ball valve bodies up to 3/4 inch, without flash (in single figure), or 1/2 inch in double figure.

– Accepts dies size 180x180mm.

– Punches stroke: 75mm.

Mecolpress has in fact the skills and the appropriate structure to make you ad hoc consultancy. Through the drawing of the piece you want to forge, we can perform a die simulation through the dedicated software in our internal technical office.

It will also be possible, if necessary, to carry out a real forging test of your piece thanks to the machines that we always have available at our company to carry out forging tests. We are thus able to offer you the machine, or the most suitable forging line for your needs.

And if the right press for you was not the ME100, we are always able to make the specific proposal for the needs of each customer, because Mecolpress has the widest range of hot forging presses of all!

Forge gate valves with a ME Hydraulic press!

In this video you can see the hot forging of gate valves with a ME hydraulic press.

Go beyond the normal criticality of the forging of these valves, get a piece without flash and reduce production costs.

What are gate valves and how they are traditionally forged?

The brass or other materials gate valves have the function of fluid flow adjusting and stopping onto a tube. They fulfil this control through a hand wheel (or a motorized actuator).

To give you an idea, you can compare the function of the mentioned valve to the closing of a gate slide in the middle of a tunnel flooded by the water.

Usually the gate valves are hot forged through traditional eccentric mechanical presses, but their realization is not easy, above all if you want to forge the part without possible defects, using little material (therefore with the most possible depth of all the holes) or without flash as well.

The traditional forging of gate valves by means of eccentric mechanical presses requires a greater energy compared to the one necessary for forging of ball valves having the same dimensions, and it requires a much higher punches stroke, in particular for one of them.

For example, for the realization of gate valves of 2 inches or more, eccentric mechanical presses of minimum 450 tons capacity and a forging tool (defined as bell tool) that allows the realization of holes of great diameter are normally used.

This technology has been valid and successfully used for many years, and Mecolpress as well proposes it to its customers through its SEO and SEO CVE CS presses series.

Gate valves forged by means of hydraulic presses

There is also a much more efficient way for gate valves hot forging: ME hydraulic press.

ME hydraulic presses, in fact, thanks to the different working dynamics of the punches, are proving to be really decisive for all the forgings of more “problematic” and complex parts, consenting for example to avoid the use of EV bell tool.

As we show in this video by means of ME presses you can forge high quality gate valves, without flash, detail of great importance. The presence of flash in the forged parts implicates a considerable waste of material, and moreover, to remove it, it is necessary to use a trimming press, which means therefore that you will have to equip yourself with an additional machine.

Another interesting aspect to be underlined is the fact that hydraulic presses have a cycle frequency significantly higher than normal mechanical presses.

Our ME hydraulic presses have also as standard equipment the Calipso software, our innovative program for collecting and checking forging data. Through this intelligent system you can perform analyses of the production process, but not only! In fact, it is possible to obtain an optimal and separate management of any pieces to be discarded or otherwise to be evaluated.

The checking of the pieces carried out by Calipso guarantees the certified quality of each piece produced.

Another important advantage that is standard on our ME hydraulic presses is the innovative die lubrication system, that can also be optionally applied to eccentric continuous cycle presses. In hot forging it is important not to underestimate the way in which the dies are lubricated; finding the “perfect” lubrication in your forging process ensures an increase in the life of the dies and materials unattainable with traditional systems!

The ME hydraulic press has an innovative forging system compared to traditional mechanical presses. Innovative because, for example, it does not generate mechanical shocks, it considerably reduces the noise generated during production, the tooling is much faster and more convenient.

Here is the video of the forged gate valves with ME hydraulic press:

The advantages of using hydraulic presses in gate valves hot forging

In summary, why should you choose a hydraulic press to forge gate valves?

- No bell EV tool,

- Gate valve without flash,

- Forged pieces controlled by the powerful Calipso software,

- Separate management of non-compliant parts,

- Better forging lubrication system,

- No mechanical shock,

- Less noise,

- More setup speed.