Brass hot forging: from the mechanical technology to the hydraulic one with me series presses

Metals hot forging is a reliable and repeatable process which allows to obtain components with high mechanical properties, minimizing the raw materials consumption.

Over more than 50 years Mecolpress has been at the service of its Customers, providing the best forging technologies that allow to maximize the products quality and the related productivity.

Not always changing means improvement, but to improve you need to change

Mecolpress is committed every day to sharing experiences with its partners to follow a common path with the aim of overcoming the performance limits of existing production processes.

It is not the strongest of the species that survives, nor the most intelligent one, but the most responsive one to changes.

Exclusively from the merge of the complementary activities:

- Development of innovative technologies;

- From consolidated experience in the hot forged parts production, the way for barriers overcoming in the productive processes can be born;

- Increase of production capacity;

- Improvement of product quality;

- Reduction of raw material consumption;

- Reduction of energy consumption;

- Reduction of resources consumption (lubricants, cooling water,…).

The experience shown in this article is related to the brass hot forging

and more precisely to the passage from the mechanical to the hydraulic technology (Mecolpress ME Series). The product subject of the evaluation is the body of a sphere valve with dimension 1” and ½. Even if it may seem a standard and consolidated product, each customer has his own design and specific features.

Mecolpress has collaborated with an Italian industry-leader company to the production of the new die and to its industrialization. After two working days and proactive information sharing, by using our ME hydraulic press, we have reached:

- Production capacity more than doubled;

- Material consumption minimized of about 6.5% thanks to the flashfree forging;

- Improvement of the workability thanks to a more uniform internal conformation;

- Increase of product quality thanks to internal defects removal.

Even if at first sight a forged part may seem perfect, its integrity can be granted only from the internal analysis.

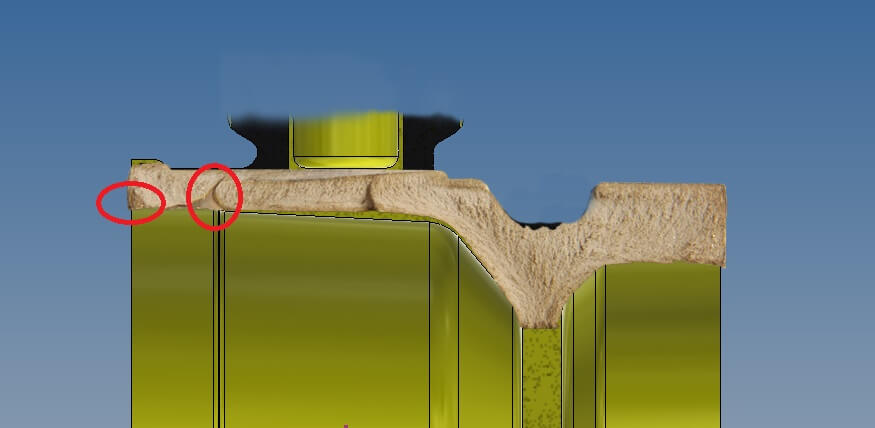

The material flow is unbalanced, the flowing speeds are not uniform, the material tends to detach from the die and to fill some areas before others (picture 1). When the flows meet each other again, they have such temperatures that they cannot be properly welded. The cold welding, indicated by the red circle, can cause problems during the machining phase, if it is included, even partially, in the surplus metal, or if during the assembly phase when the tightening torque of the front nut mechanically stresses the defected side.

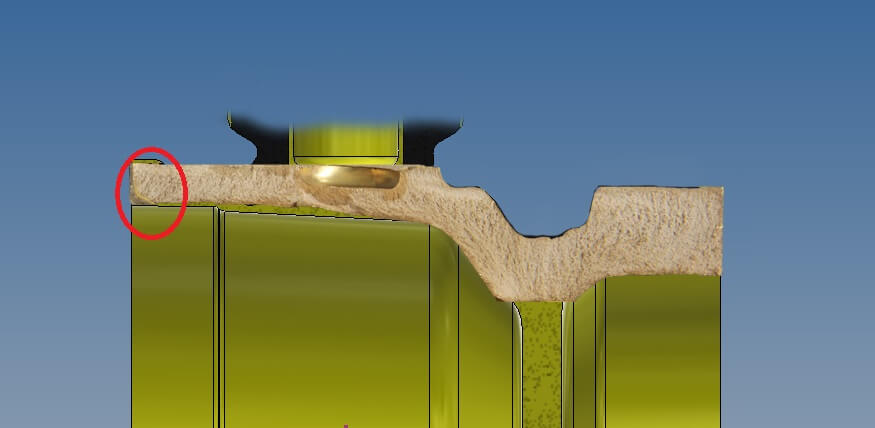

Mecolpress hydraulic presses of ME Series, even without any previous simulation numerical analysis, allow to set the correct sequence of part forming according to the material flow dynamics.

Thanks to this precious pre-forming function a progressive modification of the penetrations of the 3 punches has been applied and this has leaded to the desired result: the repositioning of the defect in a marginal zone (picture 2).

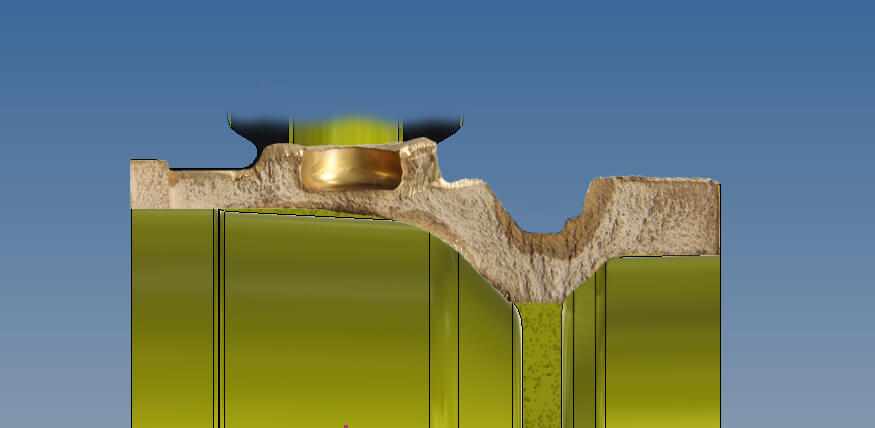

Then simple modifications to punches shape were taken into consideration in order to totally eliminate the cold junction (picture 3).

Two really efficient working days, product industrialization with new dies and more than 5500 good parts in the boxes, ready for the machining tests! A thank goes to our Customer for the precious collaboration, a thank to our team for the availability and speed of action and a thank to our hydraulic ME press that tirelessly, once again, allows to overcome the production limits and to permit a great improvement!

Wait!!! And what about energetic consumptions?!?! We are collecting data… a little patience… in the next article you will be informed about everything!