BEST PERFORMANCE IN GREEN BRASS FORGING: DISCOVER THE INNOVATIVE MECOLPRESS SOLUTION

In recent years, all production sectors have been looking for sustainable and innovative solutions, seeking alternatives with low environmental impact, based on recycling, where possible, with particular attention to the health of all of us.

The international environmental policies are trying to reduce, as much as possible, the presence of potentially toxic materials in products that are on sale and in use.

The aim is to enable a circular economy that allows the recycling of components that have reached the end of their life, preventing them from representing a threat to the environment and health. The regulations launched in the United States and Europe (RoHS, ELV, CSPIA, DWD, ..) have been adopted by most of the world’s states or at least indicated as guidelines to follow.

A relevant part of the forged brass pieces is in contact with water, even drinking water, the presence of lead increases the risk of contamination, the use of lead-free brass alloys therefore limits the health risks.

In the production of brass, the material under investigation is precisely Lead, which has always been used as an alloy element to:

- improve workability on tool machines;

- improve the quality of cast products (low porosity);

- decrease contact friction.

The percentage of lead used in brass alloys goes from 1.5 to 3.5% and is incompatible with the target of limiting its presence to 0.1% for each homogeneous material.

Using lead-free brass alloys

The companies that are involved in hot forging of brass are therefore faced with the challenging choice of using lead-free alloys, but there is no shortage of doubts:

- What consequences could, this change in chemical composition, have on the production process?

- Can the current forging capabilities still be considered valid?

- What updating\improving should be planned in the forging department?

Over the past few years, we have worked to find the answers, and based on our experience we can therefore provide some practical adviceto successfully produce lead-free brass forged parts!

Sustainable forging, how to do it?

· Bar cutting

Cutting bars using rotating disc blades is recommended to ensure correct weight accuracy.

Tool steel/high speed steel (HSS) discs are no longer sufficient to guarantee an acceptable service life. It is necessary to switch to discs with tungsten carbide base material inserts (TCT).

Below we propose a balance of the pros/cons for each of your technologies, usually when the production of lead-free brass is around 70-80% total, TCT blades are economically advantageous.

| HSS BLADE | TCT BLADE |

| Low unit cost | High unit cost |

| Extremely short service life | High service life |

| Re-sharpenable | Not re-sharpenable |

| Reduced blade thickness | Reduced blade thickness |

Oil lubrication of the blade is necessary to reduce frictional heat.

The cutting precision must be extreme to avoid problems during the forging process, especially if it is without burr\flash. The cutting machine and the blade guidance system must have an extremely rigid body. The maximum error allowed is 0.1mm.

It is also suggested an optimization of the cutting process to minimize/eliminate material waste, given the ever-increasing costs.

Modern cutting technologies allow:

- 5mm head cuts;

- cutting of the same bar with different lengths to eliminate tail waste;

- differentiated unloading for the different cuts: head, length A and length B.

· Characteristics of lead-free brass

Lead-free brass has physical and mechanical characteristics that are very different from traditional brass.

| Standard Brass with Lead | Lead Free Brass | |

| Specific Gravity [g/cm3] | 8,5 | 8,3 |

| Thermal Conductivity [W/m] | 114 | 35 |

| Electrical Conductivity [%IACS] | 26 | 8 |

| Coefficient of Thermal Expansion [X10-6/℃] | 21 | 20 |

| Liquidus Temperature [℃ ] | 900 | 890 |

| Solidus Temperature [℃] | 885 | 855 |

| Tensile Strength [Mpa] | 435 | 650 |

| 0.2%Yield Strength [Mpa] | 295 | 450 |

| Elongation [%] | 25 | 20 |

| Hardness [HV] | 140 | 200 |

Lead-free brasses are tougher, more resistant and more refractory to heat transmission.

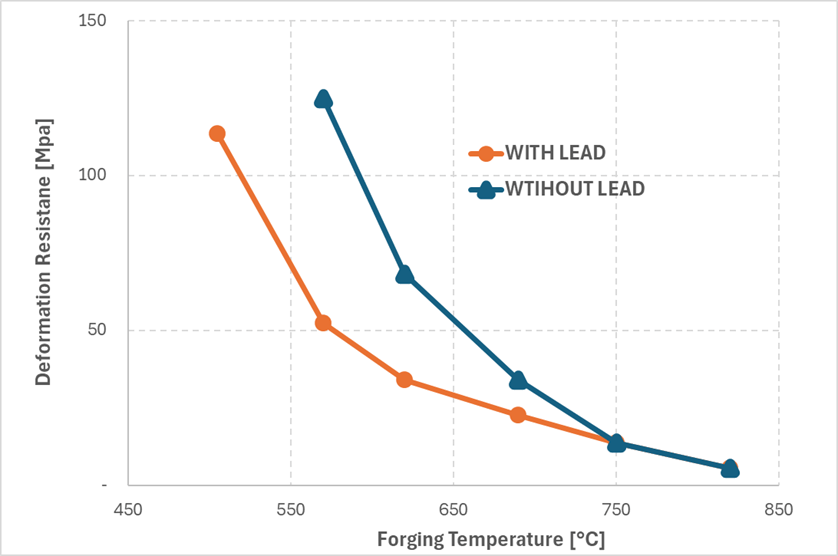

This trend is also confirmed when the heating temperature increases.

At the same heating temperature:

- Lead-free brass has a higher resistance to deformation value;

- Lead-free brass has a higher sensitivity to change in resistance to deformation in case of temperature variation.

Maintaining a heating temperature with the lowest possible variance (+- 5°C) is the key to have a reliable hot forging process.

The mechanical presses of a few decades ago were not designed with safety criteria that are suitable for these materials: simply because these materials did not exist at the time!

· Mechanical presses suitable for stamping lead-free brass

It is therefore essential to choose a press suitable for forging the new types of lead-free brass alloys.

Mecolpress SEO\HEAVY mechanical presses guarantee:

- Greater rigidity and safety margin of the structures (+50%) with capacity up to 700t.

- Greater safety margin of the transmission systems (up to +50% with epicyclic system).

- Hydraulic reaction cushions with increased capacity (+20%).

- Hydraulic cushions with SOFT IMPACT or OVERBOOST system to mitigate the impact force or increase the closing forces (+100%), with capacity up to 120ton.

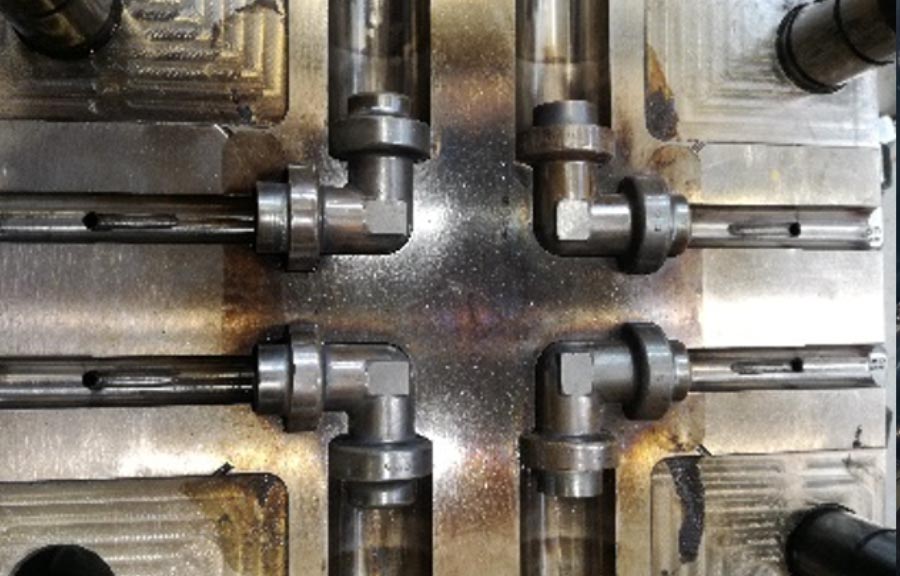

- Air\oil lubrication system up to 30 points to lubricate and cool the critical points of the die (integrated\external).

- Water cooling of the most critical components.

- Hydraulic unlocking in the slide in case of overload to preserve the mechanical components.

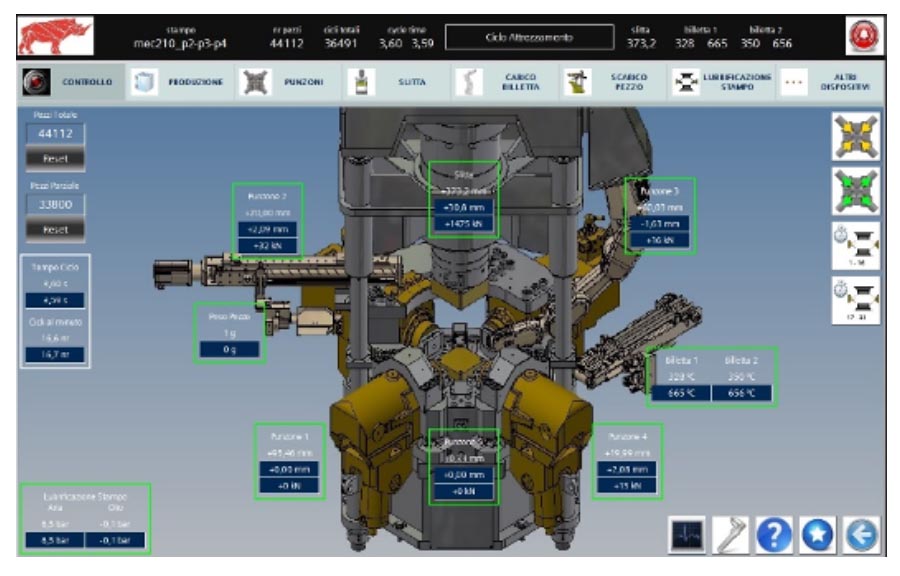

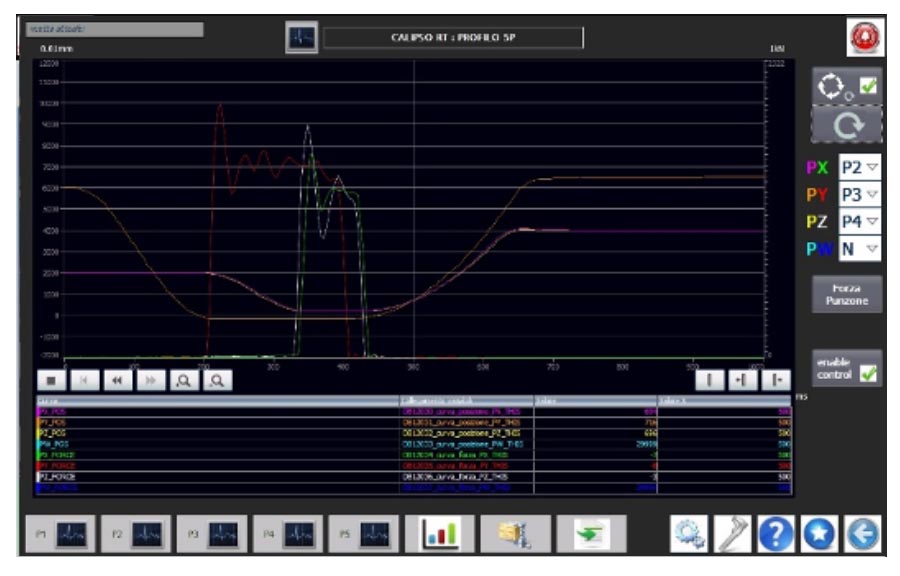

- CALIPSO control system that memorizes the fundamental parameters for each die cycle to have full control of the process.

The ME hydraulic presses by Mecolpress guarantee:

- Net die closing force up to 350 tons.

- Thrust force of the lateral and vertical punches up to 240 tons.

- Maximization of flash-free die.

- Punch kinematics system that maximizes force in the final phases of the stroke.

- Air/oil lubrication system up to 30 points to lubricate and cool the critical points of the die (integrated/external).

- Water cooling of the most critical components.

- CALIPSO control system that memorizes the fundamental parameters for each die cycle to have full control of the process.

Don’t be caught unprepared, current regulations have started to reduce the use of lead and future ones will be even more restrictive, Mecolpress’s hot brass forging technology is ready to go!

If the forging industrial process is stable and steady, it generates profit!

If the forging industrial process is stable and steady, it generates profit!

Today more than ever it is very important that the industrial process, in our case the hot forging one, remains stable and steady during operations time. As a matter of fact, by achieving this goal it is possible to generate profit.

The costs increase in raw materials, energy and specialized personnel is a more and more important and relevant constant for every manufacturing business. The profit of each order or job must always deal with these variables which can hardly be controlled.

The production stability can be controlled: the process must always be repeatable in the performances and must grant steady operative costs.

The metals hot forging is not an exception. Annual productions can reach tens of millions of pieces and each of these must be produced following the expected and planned parameters, the profit expectation must be guaranteed!

How is it possible to manage, monitor and correct tens of parameters, for millions of parts, granting the stability?

It is possible to grant the process stability even when millions of parts are produced and the process parameters are numerous, in this way:

01

=> monitoring the variability factors that influence each process to understand if they are under control or not by means of the statistical control.

02

=> Obtaining highest rigidities, forging force, and positioning precision.

03

=> Real time check of the behaviour of the main process parameters.

04

=> Modification of the main forging values without interrupting the production.

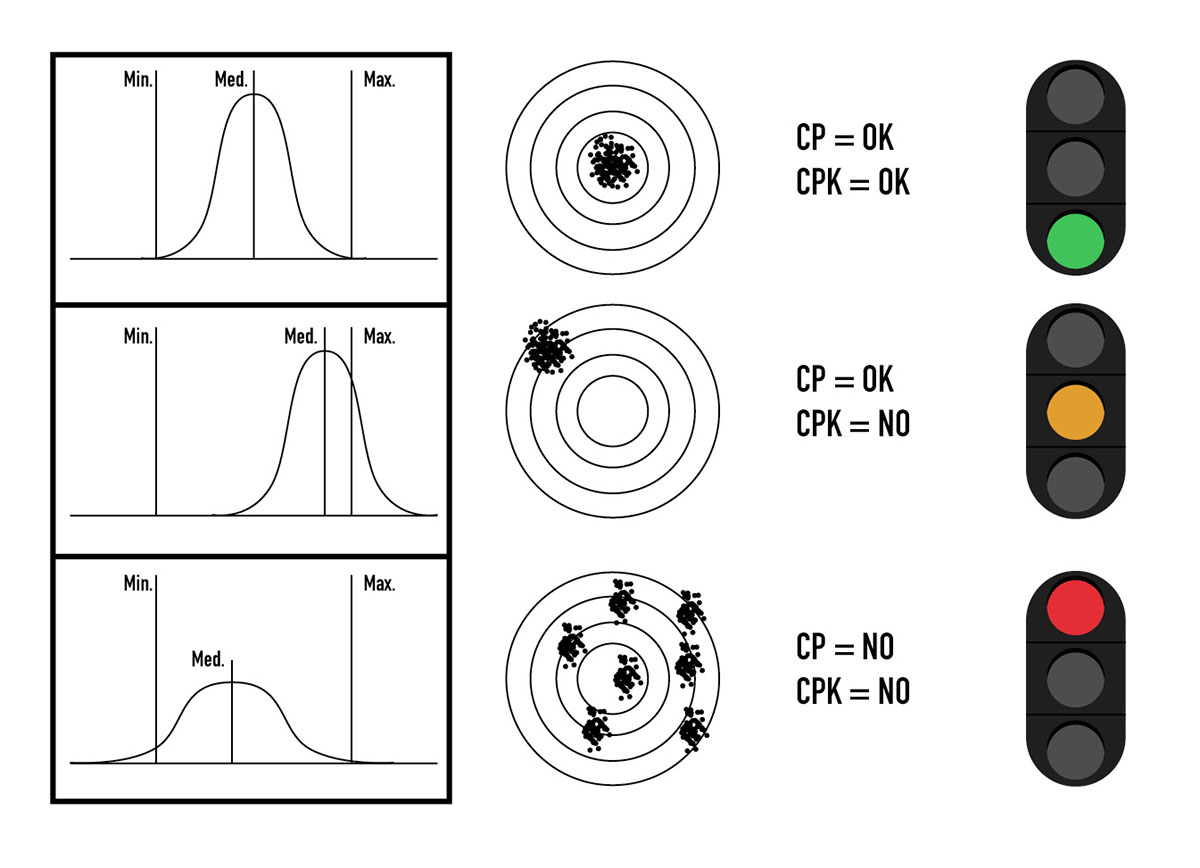

Statistics teaches that Cp and Cpk parameters are fundamental for controlling the progress of the forging process, for each variable in fact they are the key to understand its stability.

The example of the shooting with darts game allows you to quickly understand the concept:

a good Cp indicates that we are very repeatable in our shots, but it does not mean that we are hitting the target.

Only by obtaining a good Cpk, too, as a matter of fact, the optimal result is guaranteed!

=> Cp e Cpk must be much higher than one.

Let’s move on to a practical forging example:

-

Forging a batch of 25,000 water meters.

-

or forging a batch of 50,000 gas control valves

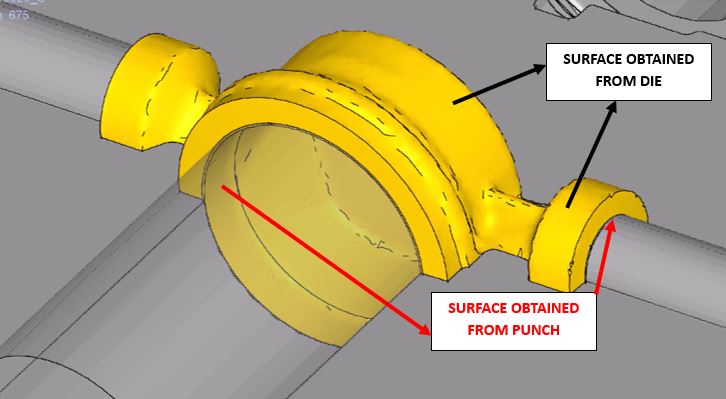

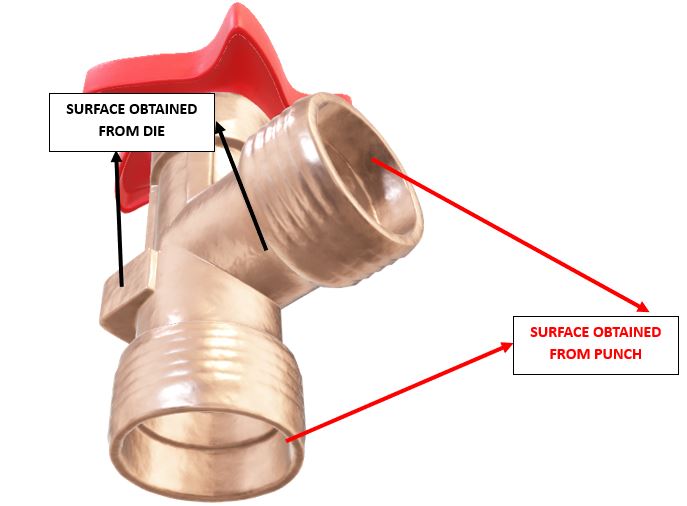

The dimensions of the forged parts are determined:

- by the surfaces of the part shape created in the die.

Cp depends on the presses rigidity performance and on the die design.

Cpk depends on the correct evaluation of the material shrinkage, which is related to the forging temperatures, to the part geometry and raw material chemical composition.

- by the punches involved in the material deformation.

Cp is obtained from punches rigidity and thrust force.

Cpk is obtained from the possibility to adjust the punch arrival position.

During the forging tests carried out with our customers from all over the world, the dimensional statistical analyses carried out on the produced samples (batches of thousands of pieces) have demonstrated that Cp and Cpk parameters were always abundantly and stably higher than one.

The complex geometries or the parts dimensions are not a problem.

How could we maintain the forging industrial process stable on our ME Hydraulic Presses?

- Mecolpress presses are equipped with Calipso software for operative parameters setting and their continuous control. Calipso, software entirely developed by Mecolpress, allows you to control the main process parameters in real time (forging forces, position, speed, …). Even before measuring the pieces, it is possible to understand if the forging process is stable and guarantees constant performance.

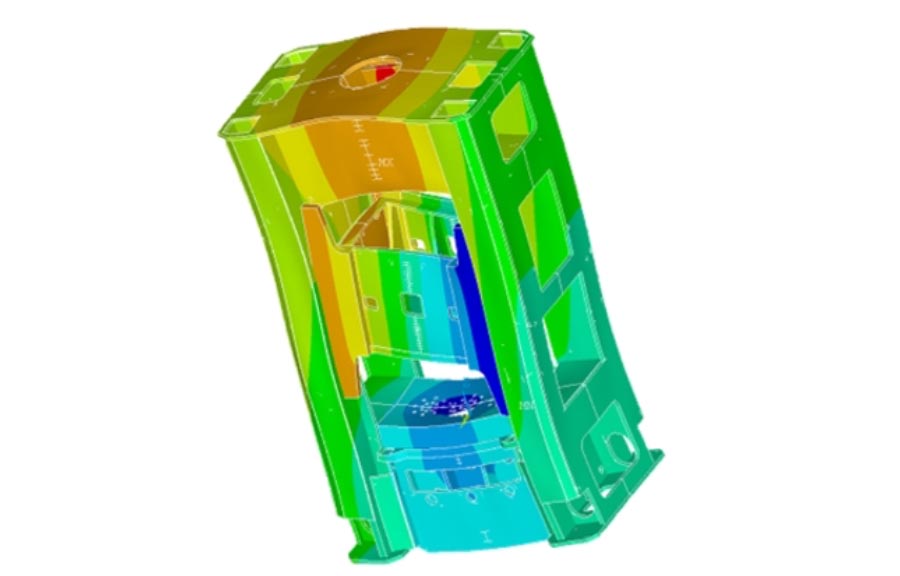

- Our presses are designed with advanced calculation systems (FEM) which allow to predict the rigidity of the components with the utmost precision, minimizing their deformations, even if subjected to high loads.

=> Cp under control

- We have designed our hot forging presses in order to have the highest possible dies closing force and maximum punch thrust force.

=> Cp under control

- The stroke adjustment of the individual punches occurs in real time, thus allowing the related dimensions to be modified during production.

=> Cp under control

- The long experience in dies design and the collaboration with the best specialized companies in the sector have allowed us to create the dies with extreme accuracy, in order to guarantee stable production of the pieces.

=> Cp under control

Reduced energy consumptions with the new hydraulic ME presses

The new Mecolpress ME hydraulic presses grant reduced energy consumptions.

How did we get to achieve this goal?

Mecolpress has been working with its customers for more than 50 years providing the best forging technologies that allow to maximize the quality of the products and the related productivity.

The forging process improvement needs do not always seem to proceed in the same direction:

- the energy consumption reduction requires the reduction of the installed power;

- the high productivity and the raw material reduction require increasing installed powers.

Our customers and partners are dealing with this conflict and are wondering how to come out as winners.

“Which is the most abundant existing source of energy? the least polluting, least expensive, most immediately available one: that is, energy saving …”

Piero Angela

What does Mecolpress propose to grant in the same page reduced energy consumptions and high productivity?

Mecolpress is not afraid of challenges, indeed it knows that these represent an opportunity to grow and improve.

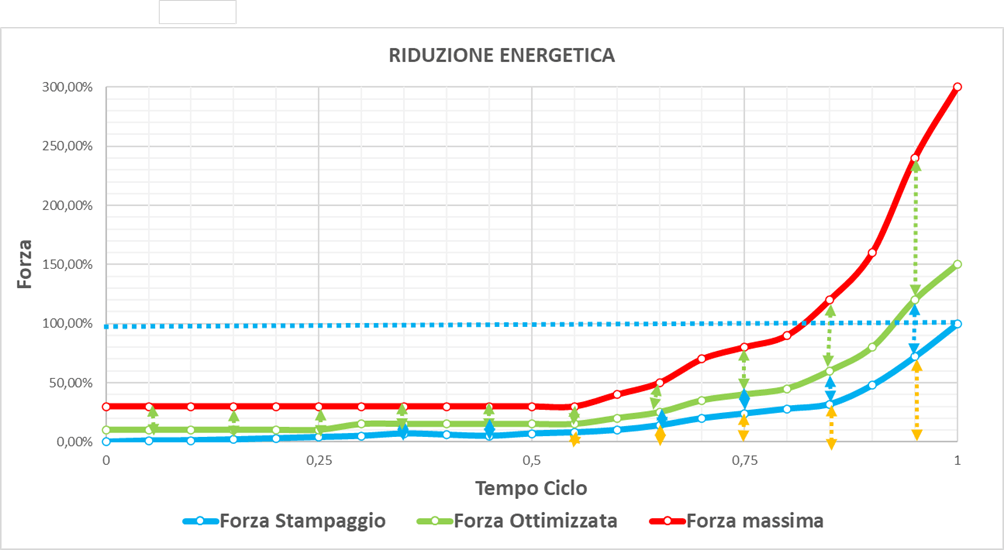

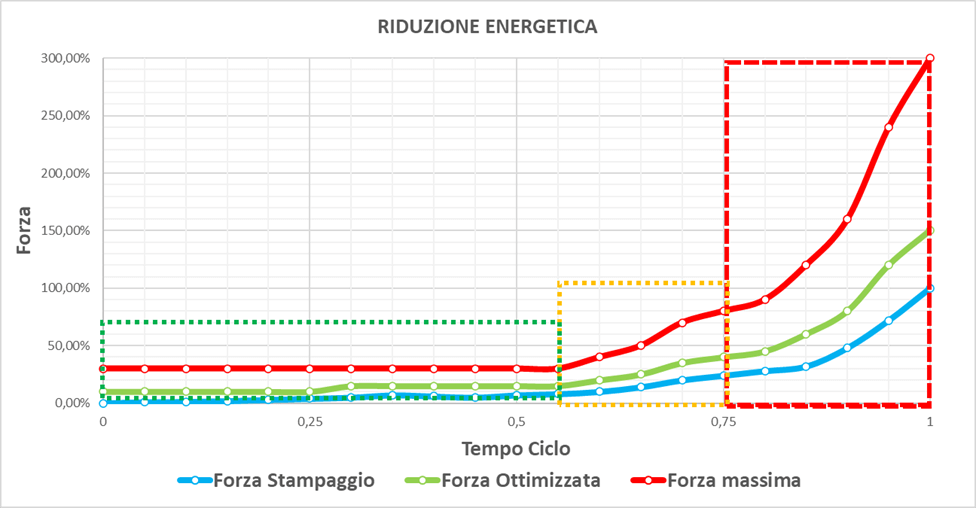

Thanks to the continuous and accurate control system, Mecolpress presses determine and memorize the process parameters at every fraction of a second, i.e. the minimum force and speed requirements to obtain a certain product with the best characteristics. Under these values it is not possible to obtain an acceptable product.

Our long experience has allowed us to evaluate numerous forging cases, from small connectors of ½” up to large valves/water meters of more than 2”, in standard and lead-free brass grades.

To reduce power when it is not needed and to maximize it when it is needed! This is the secret.

The forging process control system

The press control system learns (ADAPTIVE CYCLE) the trend of the forging cycle and regulates the pressure and the flow of the oil (REGENERATIVE CYCLE) in order to get as close as possible to the minimum forging force. A reasonable safety margin is maintained in order to compensate for eventual external parameters variation (billet temperature, material quality, dimensional tolerances, …).

During the forging cycle Mecolpress press will have three phases: power reduction, transition, maximum power.

We monitored the flash-free forging process of the body of a 1 1/4″ ball valve with a productivity of 12 pieces per minute, therefore 720 pieces per hour.

Thanks to the ADAPTIVE-REGENERATIVE cycle the energy consumption is reduced by 50%, reaching an average consumption of 45kWh.

But let’s not forget the other advantages acquired:

- production capacity more than doubled compared to the traditional cycle,

- high repeatability of the piece quality (cp>2),

- constant compliance (cpk>1.33) with very tight dimensional tolerances (± 0.1),

- minimized material consumption thanks to over 6% flash-free forging,

- improved workability thanks to a more uniform internal conformation,

- increased product quality thanks to the elimination of internal defects.

ME 350 NEXT GENERATION PRESS

ME 350 Next Generation Press: still the most powerful press, now it also minimizes the energy consumption.

ME350 press is the powerful of Mecolpress hydraulic presses: the latest version we have developed is able to grant a significant reduction in energy consumption.

Our goal is to make our customers more competitive in a very challenging market. The increase in the costs of raw materials and energy is not yet stabilized and a substantial reduction is not yet in sight. Our customers have to manage and deal with variables such as:

- product differentiation,

- the need to adapt to high volume production batches,

- managing frequent product changes,

- the difficulty of finding a stable workforce,

- the need to produce just in time,

- the increasingly high quality required of the forged product.

Mecolpress technological innovation starts from the challenges the market imposes on producers with the aim of overcoming them.

The new ME350 Next Generation press incorporates all the latest innovations:

01

Maximum dies closing force and maximum one of the independent extruder punches => flash-free forging and reduced thicknesses => reduction in raw material consumption (up to 40% compared to traditional forging).

02

Regenerative hydraulic circuit and adaptive power control to harmonize the energy consumption with the effective forging demand => reduction of electricity consumption (up to 50% compared to the presses of previous generation).

03

Anthropomorphic loading robot and quick dies changing system => increased flexibility by changing a product with another, reducing the necessary machine downtime.

04

Possibility of forging more parts each cycle in the shortest time, reaching the production of 5,000 pieces per hour => high-volume production batches are completed in a short time.

05

The production process is fully automated and connected to existing MES\ERP systems (Industry 4.0) => better staff management who can easily manage multiple presses simultaneously without stress.

06

CALIPSO Software checks the trend of the forging parameters (forces, displacements, sequences, ..) by comparing them with the references => any possible criticality on the quality of the product is overlined in real time and the part is separated from the correct ones.

All these innovations are added to Mecolpress long-lasting experience in the forging field, gained in the province of Brescia, a key area in the global panorama of the production of brass components. Mecolpress offers to the customers a vast availability of spare parts to minimize the relative delivery times and a team of specialized technicians to carry out assistance interventions all over the world.