Remote forging test

Case study: remote forging test for the acceptance of an entire line

A few weeks ago we carried out a forging test completely on-line.

Generally, it’s the customer who comes to Mecolpress site and follows all the agreed forging tests, the complete development of the necessary activities and the forging phases of the agreed parts.

For the customer this means in any case to travel, physically being absent for some days from the office and personal business, incurring more or less important costs … in conclusion facing challenges weighed down by the situation that has developed because of Covid-19.

In order to meet the need of our customer we have ensured that the forging test for the acceptance of the entire line, that has as cornerstone our ME350 hydraulic press, was carried out totally on-line.

Therefore, we proceeded this way:

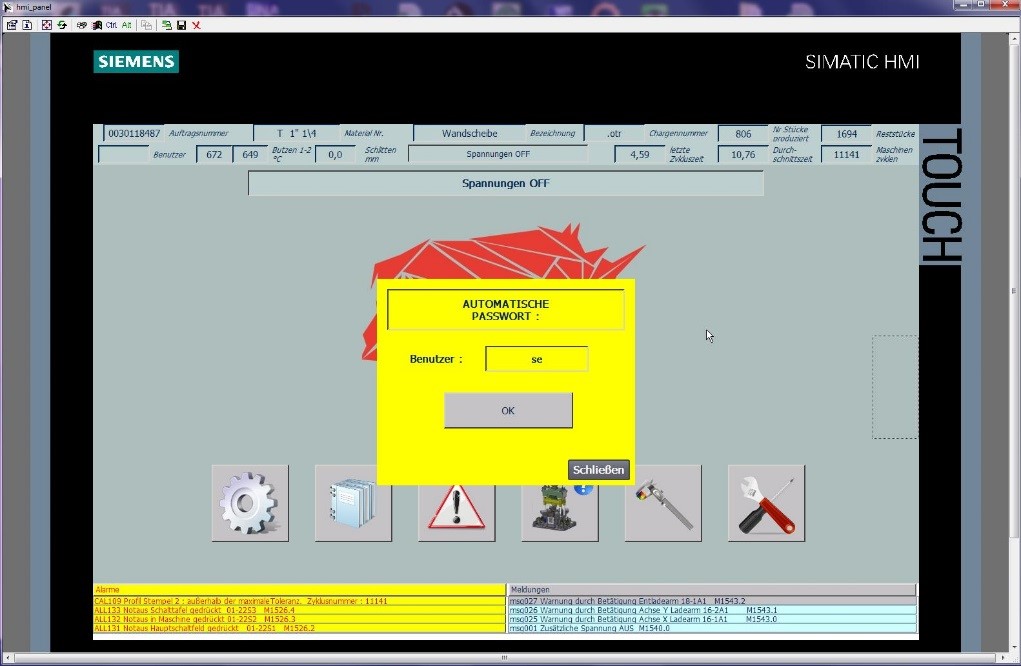

- The customer installs a software indicated by Mecolpress for a safe and certificated VPN connection.

- In this way a connection between customer internet and the press located in Mecolpress is established.

- Now the customer can access directly the machine operator panel.

4. We installed 2 video cameras, reachable by means of ip-adress, running for the whole production duration. The customer can follow the video live from any PCs.

5. Always only inside the established VPN it is possible to access through browser to the two cameras that are always on during the entire forging phase.

6. A technical support representative in Mecolpress is always and in any case available by telephone.

7. All the procedures regarding the setup phase and in particular the die changing phase are visible.

8. All the videos and pictures are therefore strictly confidential and visible from a webcam only to the customer that can save videos, if he considers it appropriate, or taking some pictures, everything always with the maximum confidentiality.

Which have been the advantages for our customer?

The advantages resulting from this acceptance-from-remote procedure of an entire hot forging line are easily identifiable:

- Time-saving,

- Costs-saving,

- Possibility that more people can follow the forging test, comfortably in front of a PC.

New procedures for remote tests

These methods of digital implementations are fundamental, but we still believe that in the world of precision mechanics and capital goods, the aspect of customer consultation is crucial and that as a result the personal contact is still necessary to carry out efficient projects according to partnership optics with the customer and to a deep understanding of his necessities.

Anyway, it is important to offer to our customers the alternative of remote forging tests. The customer experience is however total: video connections, real time data extraction, possibility to access to the press panel.

This procedure can bring also to future developments, for example, let’s think about how it can be useful if it would be set up on the contrary: a Mecolpress technician could have all the useful tools for diagnosing a problem on a machine located in Australia and solve it immediately! Without taking the plane, without taking a long journey, without charging important costs to the customers, avoiding long machine stops.

STEEL HOT FORGING: THE WORD TO OUR EXPERT

We interviewed Luca Di Donato, Mecolpress specialist for steel hot forging.

Steel is a far different material from brass, for this reason Mecolpress has decided to increase its team with a devoted figure, to whom we have addressed some questions.

Let's talk about steel hot forging

What is your role in Mecolpress?

The role I currently play in the company context is project engineer manager specialized in steel hot forging and non-ferrous alloys (except brass).

Specifically, I mainly deal with the identification and definition of the hot plastic deformation process that is technically and economically most suitable for the production of semi-finished steel components but also aluminium and special nickel and Titanium alloys.

What kind of experience do you have in steel hot forging sector?

The gained background in the specific sector derives from many years of work experience acquired in the company field, initially as a designer and then as technical and operational director of companies located in Italy and abroad.

Which application sectors do usually use steel hot forging presses?

Presses for steel hot forging are widely used in many application sectors such as automotive, aeronautics, agriculture, construction, chemical, petrochemical and industrial sector in general.

Which type of machine is most suitable for steel forging? (mechanical presses, hydraulic presses, screw presses?)

From a metallurgical point of view, steel can be forged using every type of press, since the types of steel in general are little affected by the presses deformation speed as some aluminium alloys and the super alloys of Titanium and Nickel are affected.

Therefore, there are other parameters that influence the choice, in fact the geometry, the geometric and dimensional tolerances can certainly guide the choice on a mechanical press rather than on a screw press, but also on a hydraulic press.

Compared to brass, which are the distinctive traits of steel?

From the process point of view and therefore from the point of view of the relative presses, the first aspect that is typical for steel is certainly the forging temperature which is around 1200 ° C.

The other equally important feature is the steel deformability which is far more difficult than the one of the brass. The resistance to hot plastic deformation of steel forces the adoption of simpler geometries, the adoption of presses with increased capacity in terms of forces, moreover, pre-forming processes are often used.

According to your experience, which are the recurring critical issues that you could observe in the forging of this material?

As previously highlighted, steel is forged at high temperature, therefore possible overheating can be created in areas that are particularly subject to deformation, the involved forces are important and as a result the energy and disposition can approach the limit and cause no geometric conformity on the piece.

In the end, steel cannot be easily deformed and therefore it requires a specific study to understand which preforming processes are better to adopt in order to avoid cracks / folds of material.

Always according to your experience, when we want to choose the most suitable machine, what should we absolutely consider?

Obviously the geometry of the forged product to be obtained, together with the imposed geometric and dimensional tolerances, strongly influences the choice of the best process, first of all the type of press but also all the machines necessary to compose the line, from the cutting, heating, and preforming process up to the possible calibration of hot / cold forging.

Mecolpress, through the specific skills acquired in fifty years of working history and thanks to its professionalism, is able to support the customer from the very first stages of defining the most suitable geometry for the choice of the forging up to the realization of the line, also fully automated, turnkey.

What do you think that can really make the difference in a “guessed” press?

The heart of the production line in its entirety is the PRESS which has been designed to respect specific characteristics, as a result “guessing” the type of press is absolutely important, but it is equally essential to consider who designed and built it, in this regard the presses produced by Mecolpress are considered to be among the best on the market, both in terms of technological content and in terms of rigidity and reliability.

If you want further information regarding the topic “Steel hot forging”, we invite you to consult the U.NI.S.A. Italian National Union of Steel Forgers, of which we are aggregate members.

Why to choose Mecolpress presses?

Mecolpress makes available to its customers quality presses and all its technologic know how. For those who need high performing machineries for hot forging we are a reliable and with a solid experience partner in this field, gained in many years of activity.

Whether it is an entire forging line or a single machinery, Mecolpress can suggest the most performing solution for production and offer a technical support able to face every need.

A first meeting to understand the necessities

When a new potential customer contacts us expressing its need to buy a press, our sales department organizes immediately a first meeting either at customer’s or at our premises in order to show the different machines and their functioning.

During this phase, to us it is of fundamental importance to understand the types of the parts to be forged and which could be the eventual criticalities connected to the single parts in order to be able to propose the most suitable press. In many cases our offers are based directly on the drawings of the parts to be forged that are analyzed by our technical office in great details.

In order to understand which is the best press, our technical office takes advantage of a software that can simulate on the computer the action of the machine. In this way we provide a valid tool for the identification of the machinery that meets the productive needs.

Some customers in addition to the single press require the entire hot forging line and, in this case as well, we can provide all the necessary machineries, and to optimize the production.

Forging tests at Mecolpress

Once the most fitting press for the customer has been identified, even if this is hydraulic or mechanical, we carry out forging tests at our premises. So, the customer can be sure in advance of the final result before starting the production at his premises.

In order to carry out the test, the dies for the realization of the wished parts are mounted on the machine. In case the customer does not have the die, there is the possibility to commission it directly to Mecolpress. Indeed, our company offers a complete service to support the customer during all the productive steps and can also offer this component.

During the many years of activity we have gained high technical skills and we have confronted with different situations. The gained experience has turned us into a partner that can understand the forgers needs, able to propose mechanical or hydraulic press for a specific production type.