Hot forging in the fashion sector

Hot forging presses are also used in the fashion industry manufacturing.

The worldwide fashion sector is characterized by extremely significant business volumes: around 3 thousand billion euros and it employs 50 million people.

Italy is one of main districts for the fashion industry with historic brands and production chains deeply rooted in the territory.

The sector is affected by global uncertainties linked to inflation, geopolitical tensions, post-Covid recovery but double-digit growth is estimated in the coming years. The increase in business volume is possible thanks to a high dynamism full of creativity and style which canalizes an important flow of news and innovations every season.

The digitalization of sales channels and operational departments and the near-shoring approach have created the need to make the manufacturing process increasingly productive and efficient.

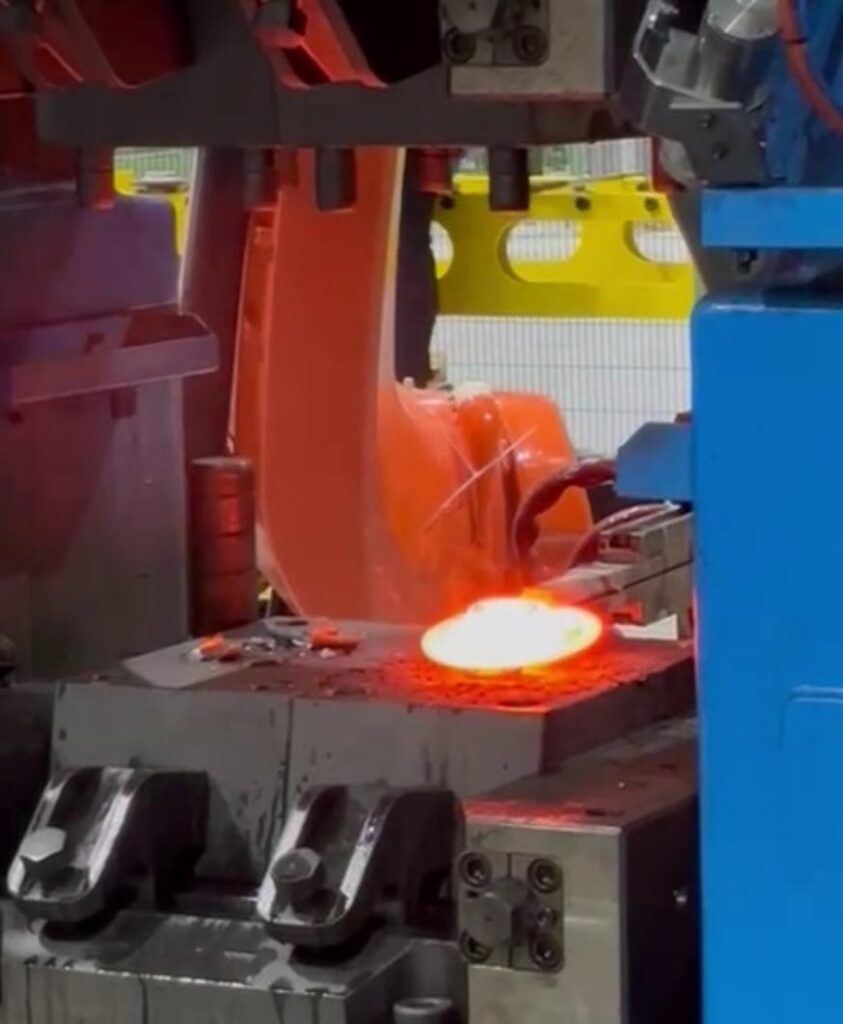

Metals hot forging is a key operation to characterize fashion products and accessories. The logos of the major brands applied on bags, shoes, clothes and belts are made through hot forging and then finished with other downstream processes.

Mecolpress has been the protagonist of this continuous growth process, offering technologically advanced forging solutions with the aim of:

- Increasing production capacity up to 1500 pieces per hour;

- Reducing machine downtimes due to maintenance and tool changes (availability >95%);

- Reducing the consumption of materials, energy and CO2 emissions by 50% (GREEN TECHNOLOGY Industry 5.0);

- Allowing the digital communication between production line and company system and remote diagnostic access (Industry 4.0);

- Flexibility in forging products of different sizes and materials (steel/brass/aluminium);

- Increasing the safety of the production line by reducing human intervention (industry 5.0).

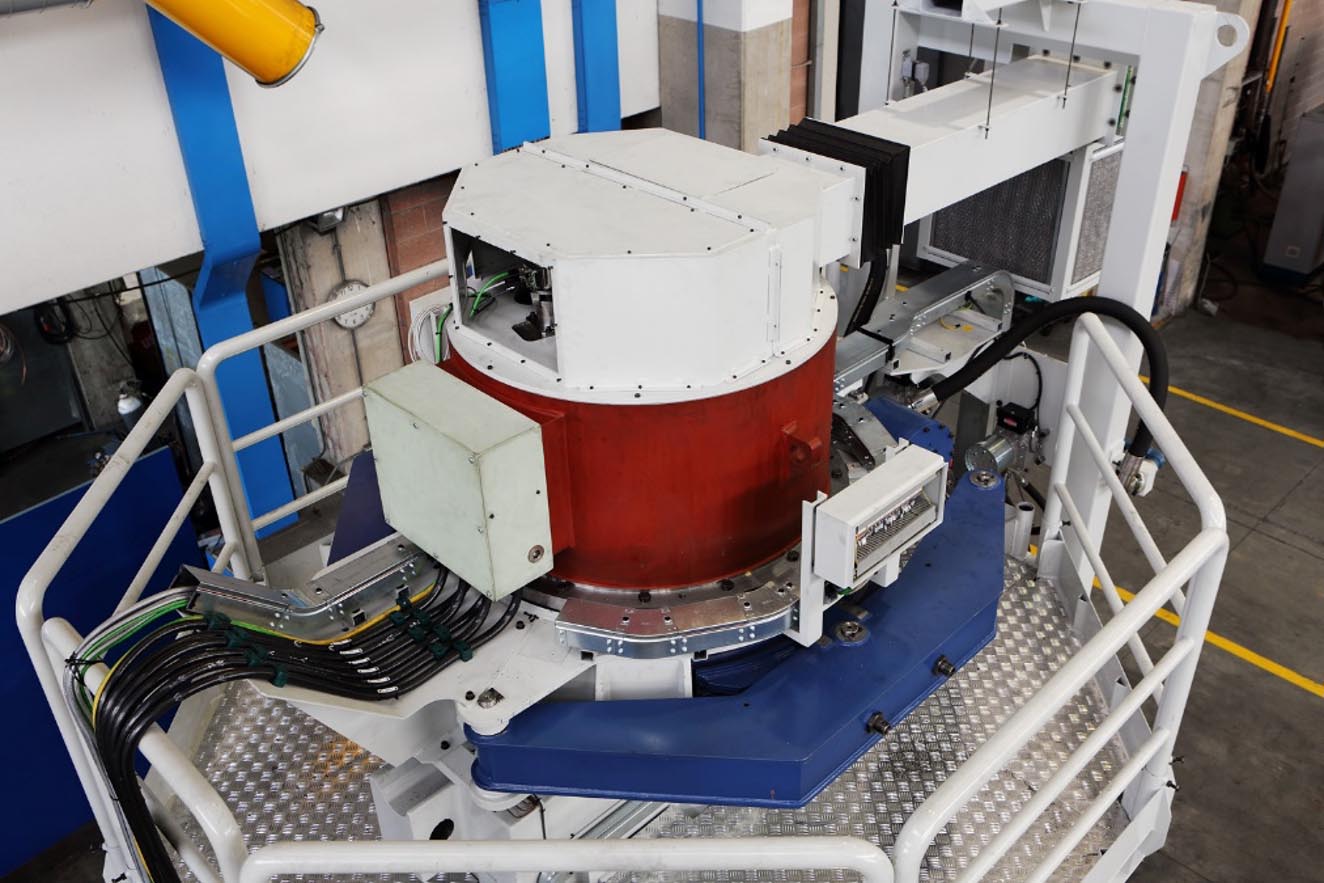

TDS Electrical Torque-Driven Screw presses

TDS Electrical Torque-Driven Screw presses result to be particularly suitable for the hot forging of parts destined to fashion sector.

Here below the 4 strong points that make many customers to prefer these hot forging screw presses:

- Cycle time does not dependent on forging energy => always optimized productivity

- Reduction of friction parts => less maintenance and less energy consumption

- Flexibility in energy settings => production flexibility for product size and type of material (brass, steel, aluminium) and reduction in dies wear

- Energy recovery of braking energy => reduction in energy consumption

Click on the image to enlarge

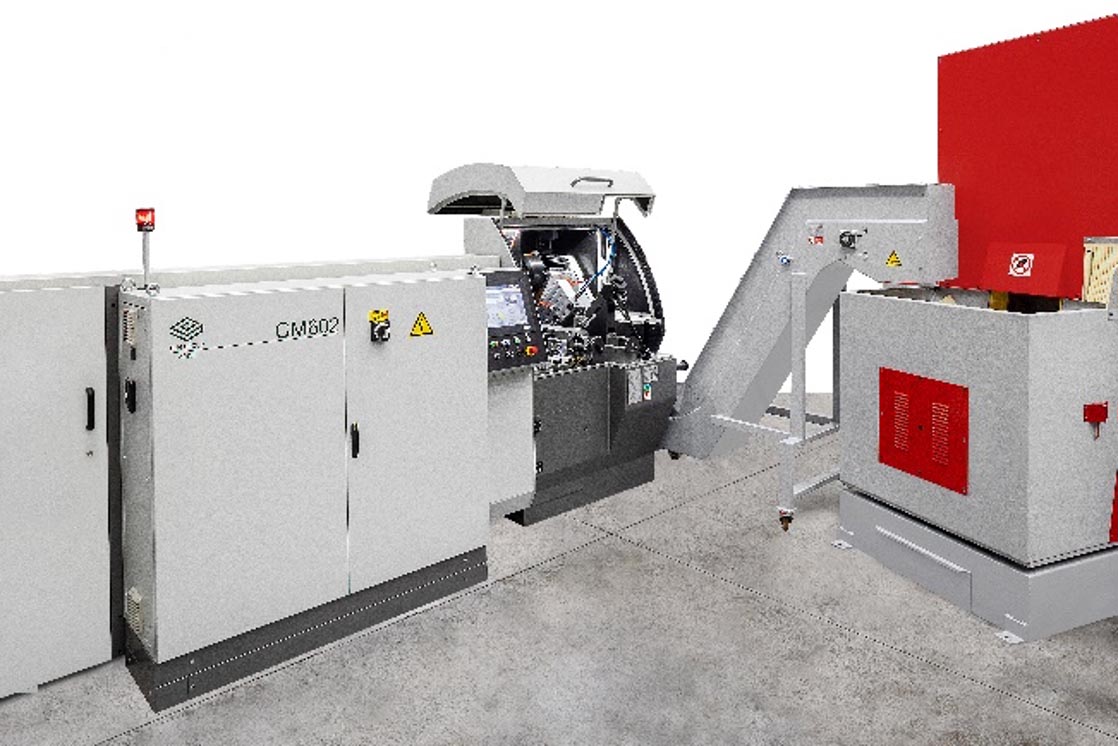

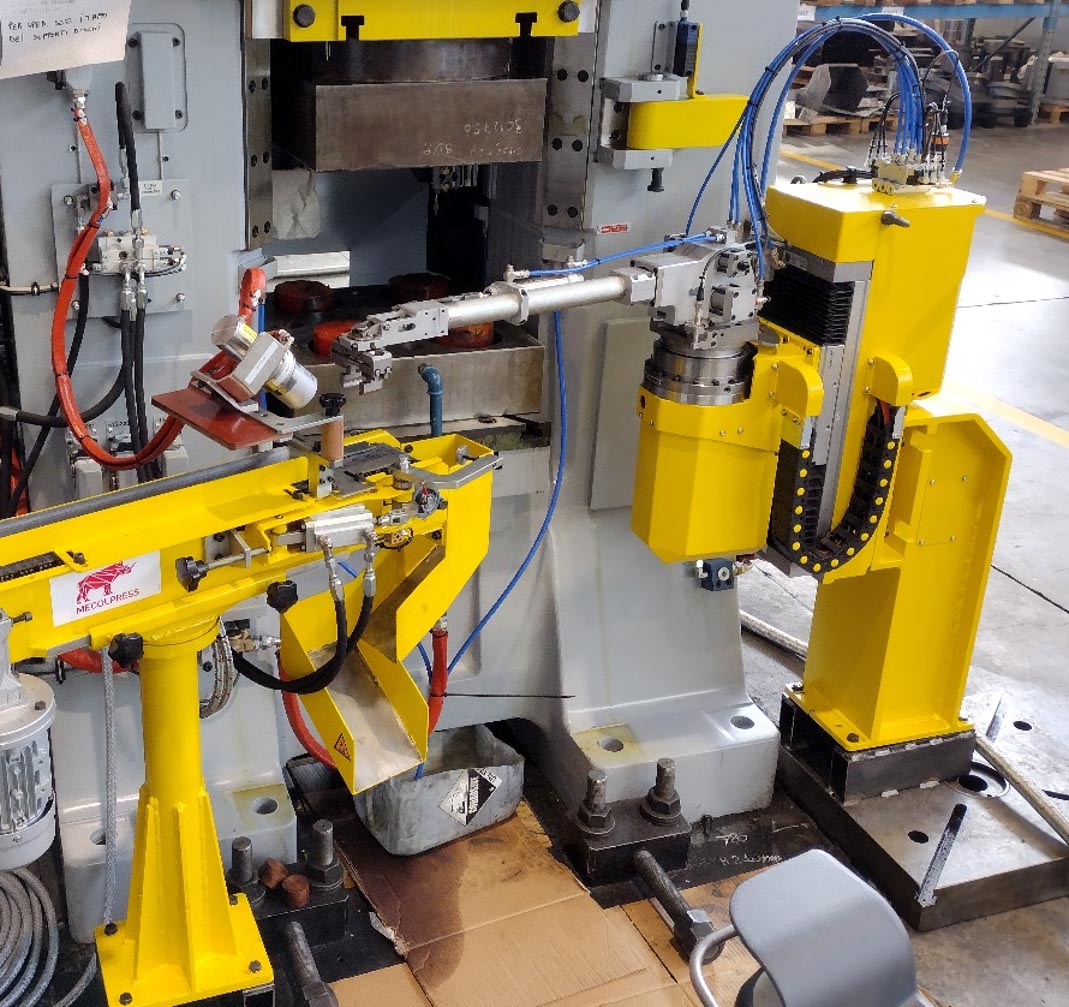

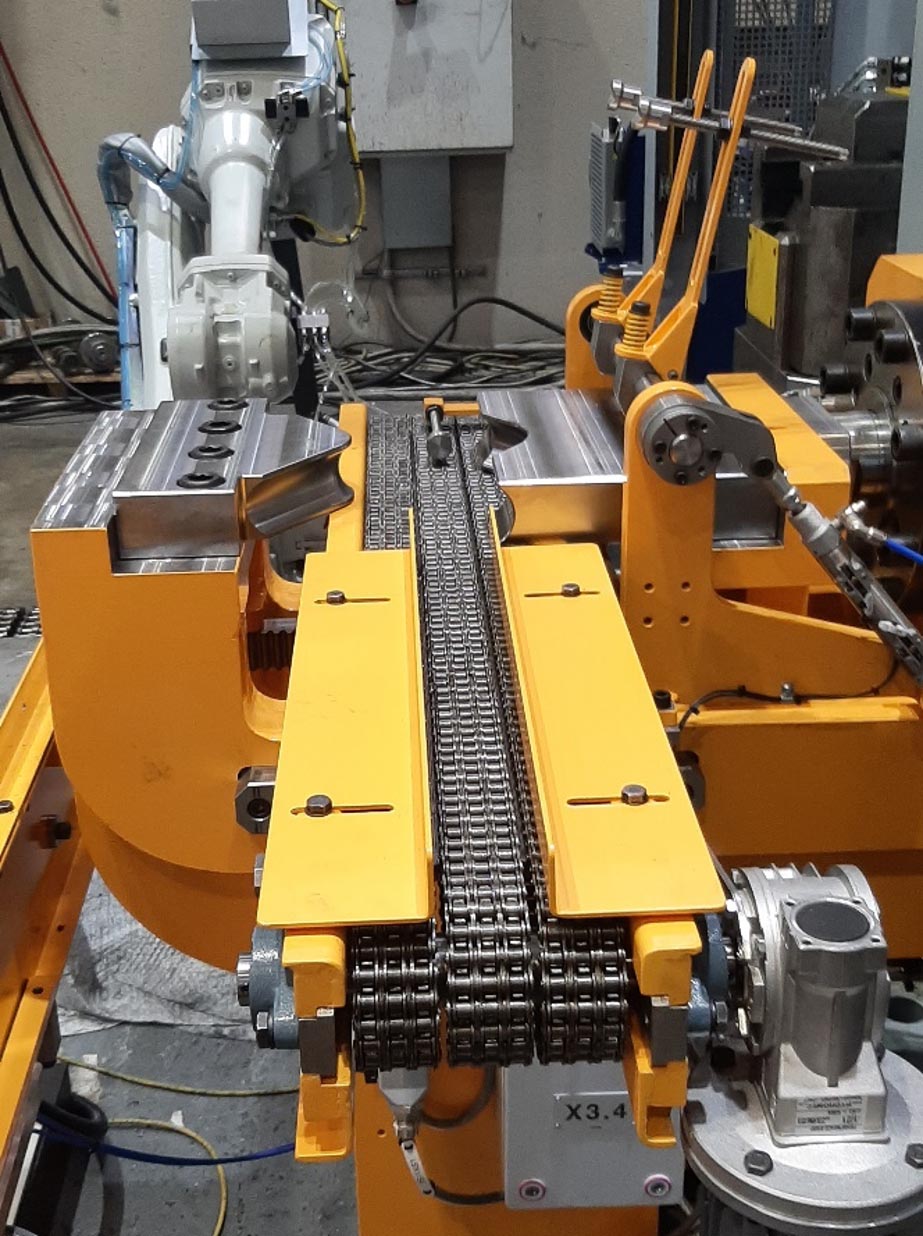

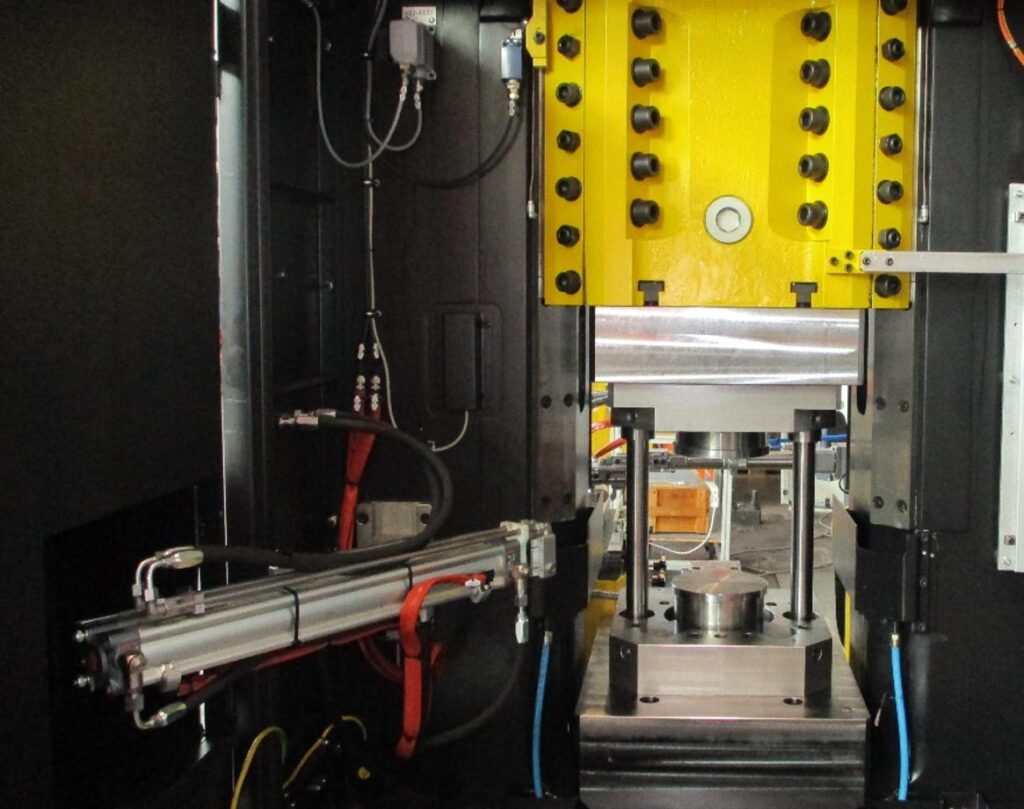

Complete forging lines integration

Even in the fashion sector, the frequent request is to have complete forging lines.

We can supply the line following the customer need, so in addition to the hot forging press, we integrate the cutting, heating, forging and deburring of the forged pieces.

Click on the image to enlarge

The presses for forging of parts destined to fashion sector have to optimize the process phases:

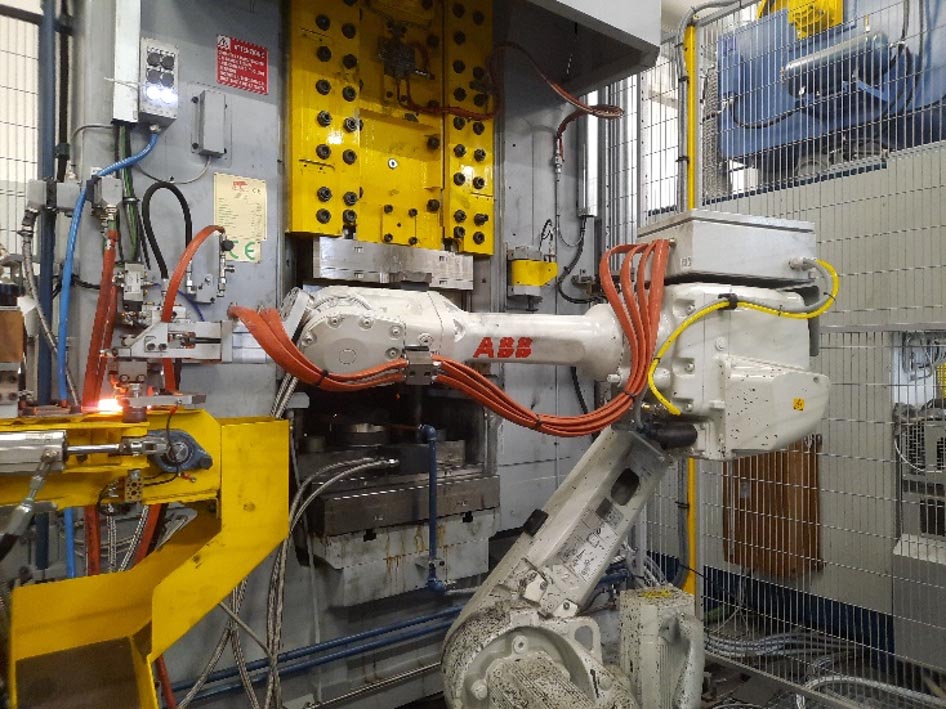

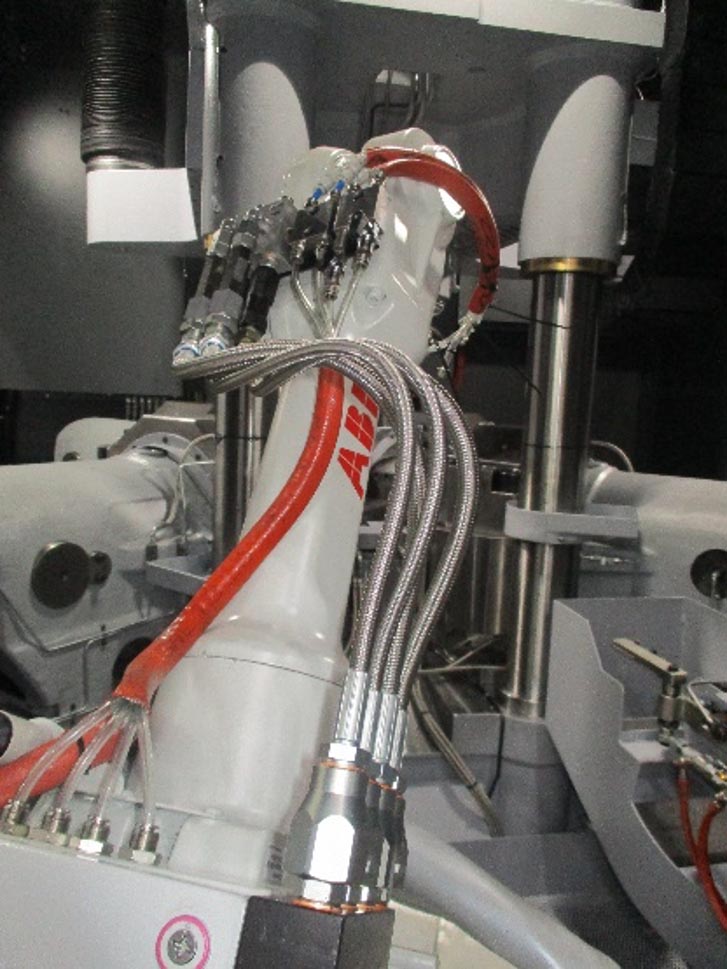

Automation of machine loading and unloading

We underlined the importance of automating the loading and unloading phases of pieces. The presses must include certain solutions to guarantee maximum performance:

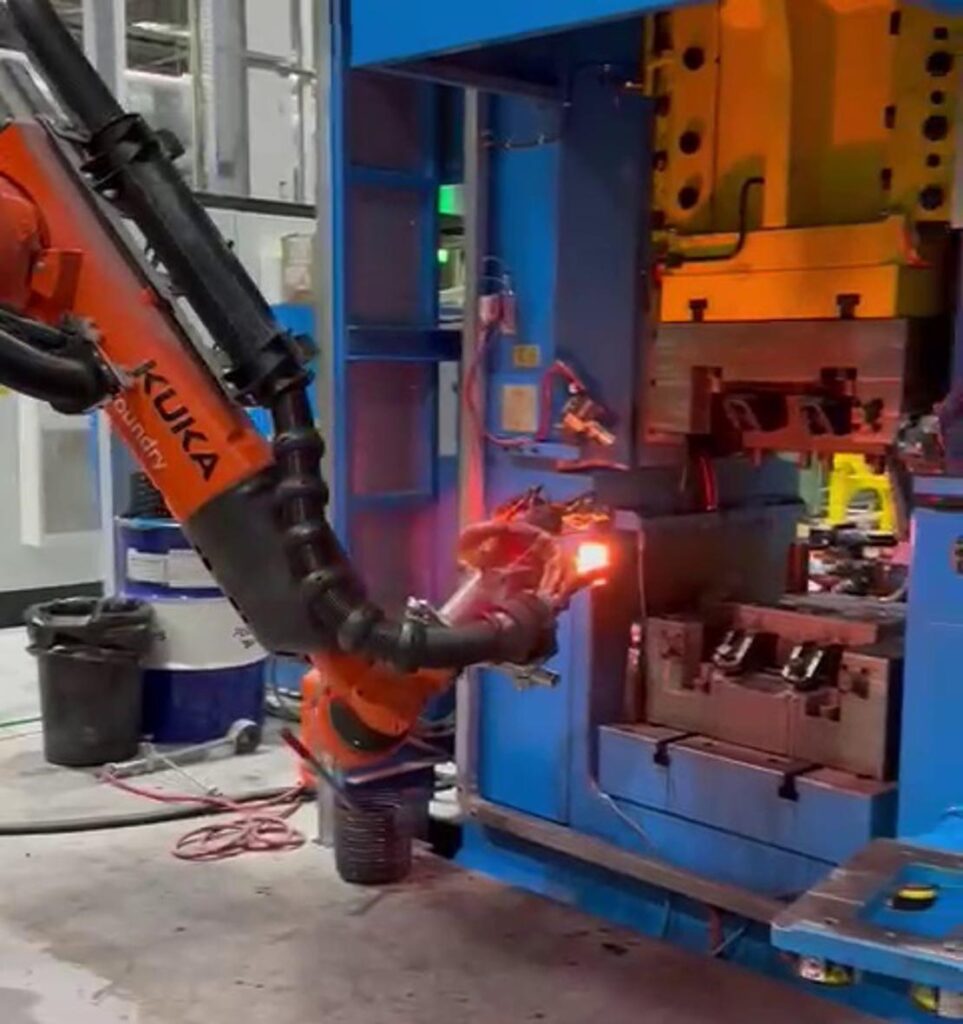

- High-speed Cartesian systems for heated material loading.

- Flexible anthropomorphic robots for heated material loading.

- Unloading of the forged product via air blow to avoid sliding and contact defects.

- Folding of the material to be forged to have a shape as close as possible to the forged parts and to reduce material consumption.

- Possibility of different shapes of the starting material from the traditional round billet to customized shapes (letters, symbols, …).

Click on the image to enlarge

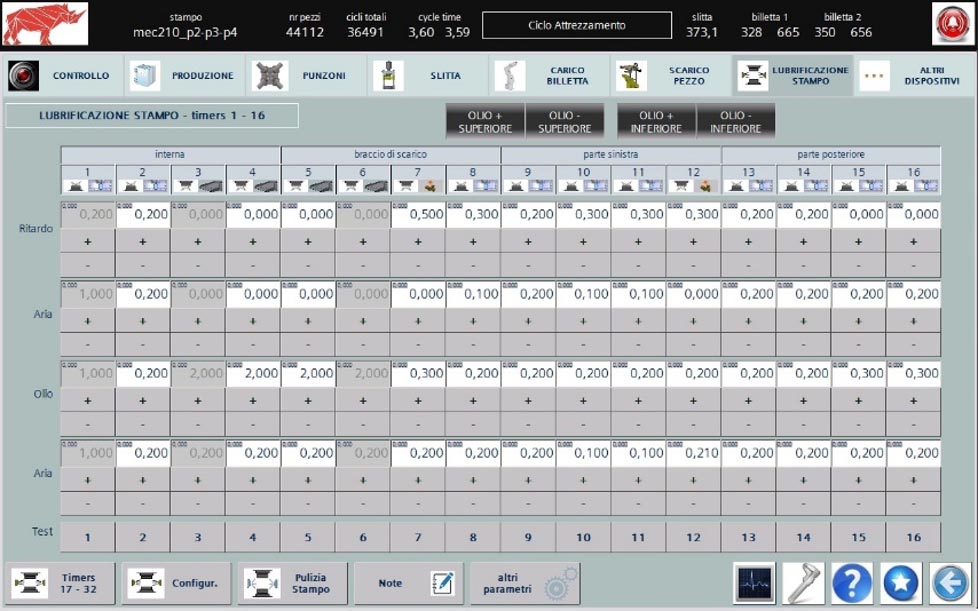

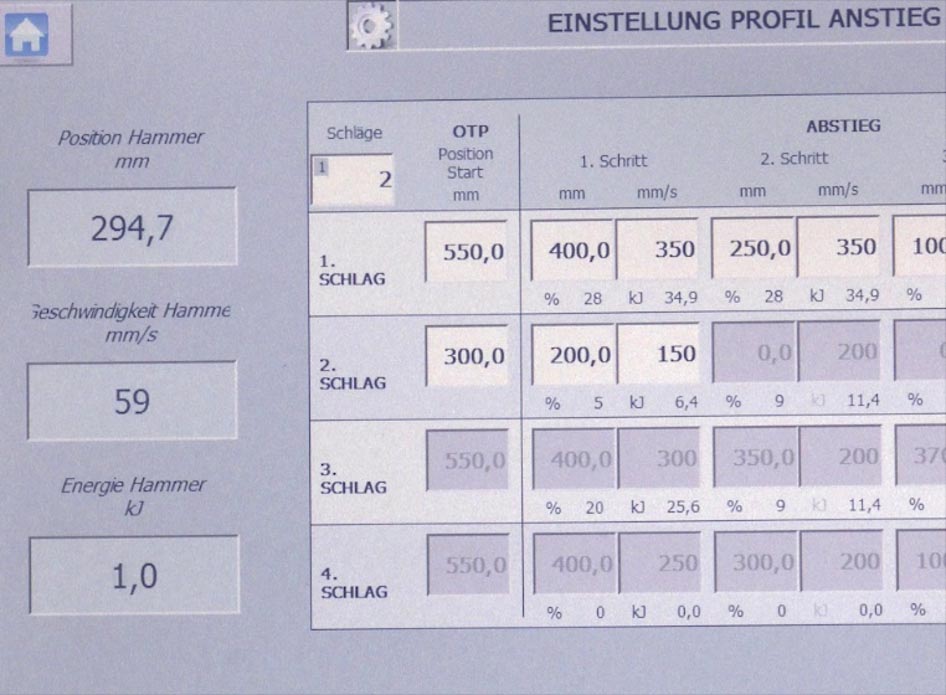

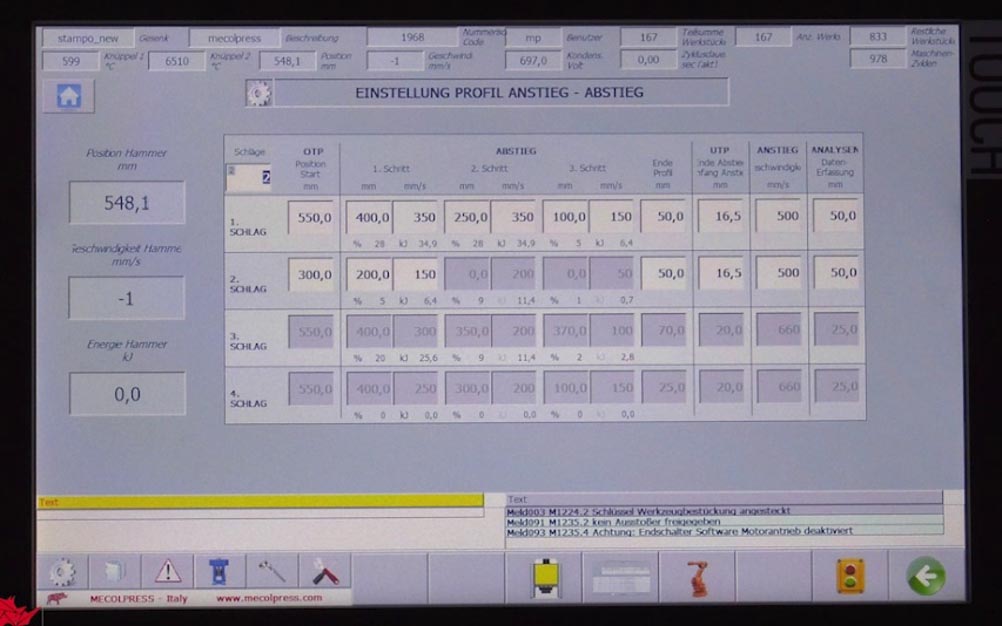

Productive process data control system

An important solution to take into consideration to start a successful hot forging project for parts in the fashion sector is certainly to equip yourself with a control system of the productive process.

Mecolpress Calipso Software allows to monitor and to adjust the data connected to forging process, and it presents numerous advantages, among which:

- Based on HMI architecture complete with touch screen display

- Functioning parameters of the press and of the auxiliaries that can be inserted from the display.

- For each forging cycle, the main parameters are saved for collection and analysis.

- Integrable with company MES/MRP systems.

- Remote access for diagnostics and problems solving

Click on the image to enlarge

Dies lubrication

The proper dies lubrication makes the difference for a successful hot forging process.

A correct lubrication does not mean a lot of lubrication, but it must be properly dosed, the most suitable lubricants must be chosen based on the metal to be forged and the required piece.

We propose:

- Automatic air-oil lubrication unit managed by the control panel.

- Up to 30 lubrication points.

- Automated lubrication arm synchronized with the forging cycle.

Click on the image to enlarge

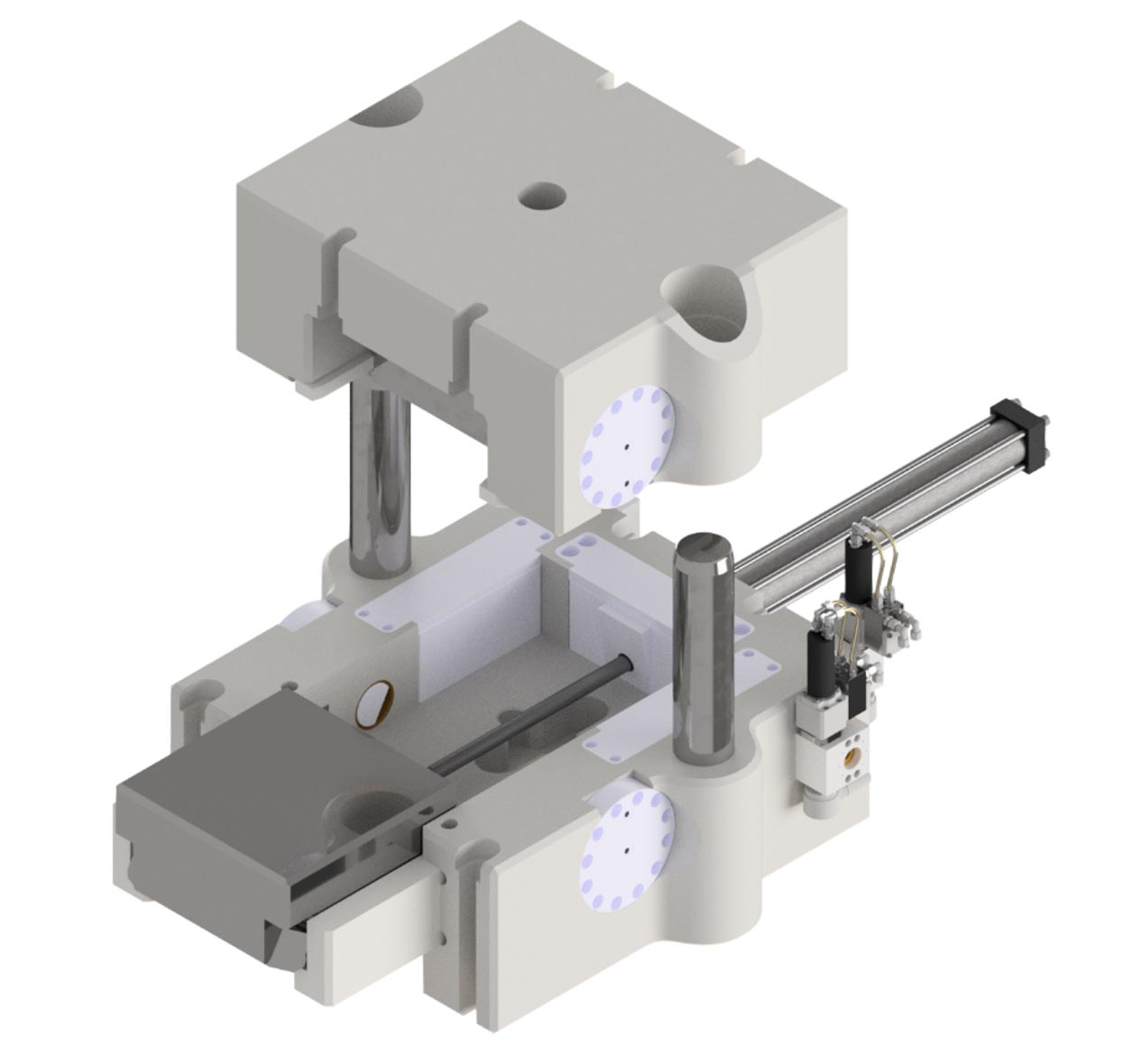

Dies changing system

To allow a quick unlocking, the die holder has been optimized, and the auxiliary arm becomes essential for bringing the dies out of the working area of the press.

Click on the image to enlarge

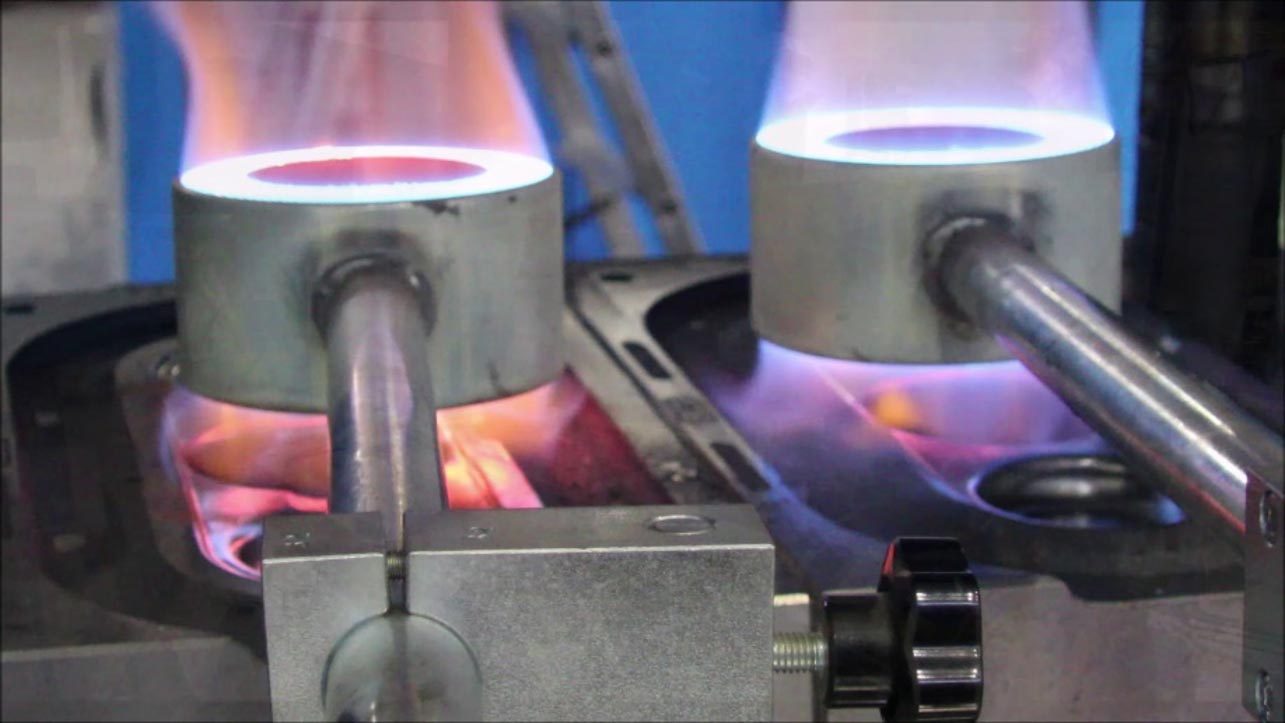

Dies pre-heating

This is an important phase of the hot forging productive process that foresees the use of modern induction technologies avoiding open flames or CO2 emissions.

In the fashion sector, therefore, hot forging presses and related devices are widely used.

It is always important to develop an accurate and successful forging project to maximize profits and reduce waste.

Friction Srew Press – MECSPE 2020

Mecolpress will partecipate in MECSPE, at Fiere di Parma from 29 to 31 October 2020.

We exhibit the FPN 220 friction screw press.

For 19 editions MECSPE has been the greatest event focused on innovations for the manufacturing industry.

The numbers of Mecspe:

135.000 SQUARE METERS

56.498 VISITORS

2.306 EXHIBITORS

12 THEMATIC SHOWS:

360° innovation, the fair offers a complete overview of innovative materials, machines and technologies, Industry 4.0.

This event offers an interesting moment of meeting between companies, professionals and associations to build new opportunities for the manufacturing market.

Get your free admission ticket

To facilitate the visit and access safely, it is advisable to register to get the free admission ticket.

You can request it by simply filling out this form:

This ticket will allow you to access the exhibition area, participate in conferences, attend the demonstration areas and special initiatives of Mecspe 2020, and take advantage of free parking.

You can find us here:

MECOLPRESS

Hall 8 Non-ferrous materials and alloys, Stand M24.

For the 2020 edition of MECSPE, Mecolpress exhibits the FPN 220 Friction Screw Press

The screw presses like the one we bring to MECSPE are used for the hot forging of brass and steel parts, or with any type of material in general.

They are characterized by the production of solid pieces, or that require multiple forming steps.

Find out more by consulting the screw presses category on our blog.

We are therefore waiting for you at MECSPE!

MECSPE

Location: Fiere di Parma

Address: Viale delle Esposizioni, 393A – 43126 PARMA (PR)

Date: 29 – 31 October 2020 – Thursday, Friday, Saturday

Opening Hours: 9.00 – 18.00 (Thursday and Friday); 9.00 – 17.30 (Saturday)

Visitor entrances: Reception Sud, Est, Nord, Ovest

Visitor Parking: adjacent to the entrances

https://www.mecspe.com/en/magazine/

The excellence of technology applied to industry.

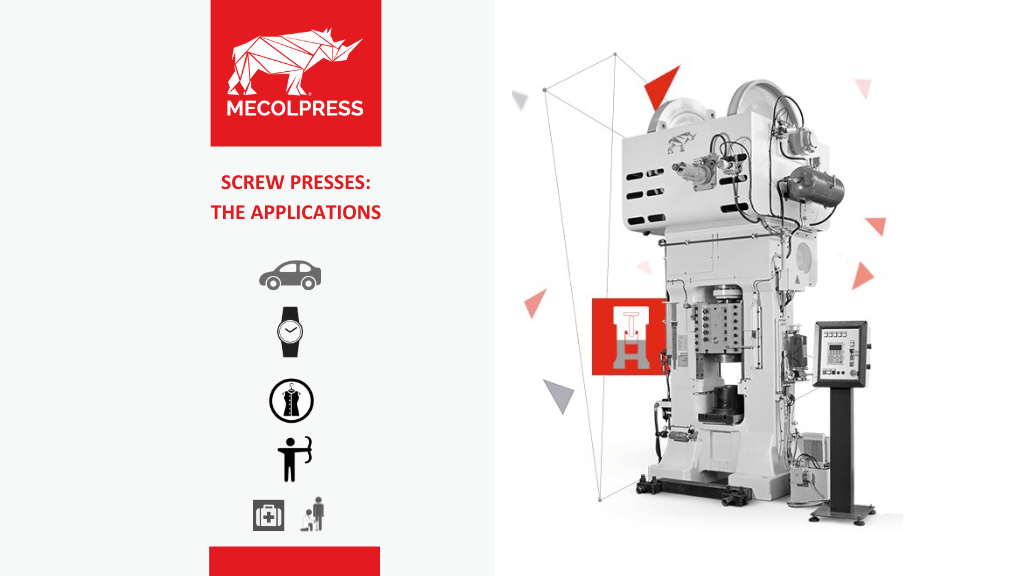

Screw presses

Come to discover the application sectors and the functioning of Mecolpress screw presses. Used for hot forging, these presses can be employed with every type of material and are distinguished by the realization of full parts.

Screw presses functioning

Mecolpress offers a wide range of presses both hydraulic and mechanical. Also screw presses fall into this last category, ideal for hot forging of parts of great dimensions or that require more passages for shaping. These mechanical screw presses can be provided with a disc friction control or a direct control with electric servomotor.

The screw press choice is determined according to the type of part you want to forge. Hallmark of the screw press is its ratio force-machine dimension, that results greater than the specific one of an eccentric mechanical press.

These mechanical presses can be used with every type of material and the frequency of strokes is quite reduced. For this reason, there is a tendency to use this machine for the production of little batches, that is often true for parts of great dimensions.

Mecolpress offers to its customers three lines of screw presses: Dellavia series and Osterwalder series that are friction screw presses, and TDS series with electric motor. All the screw presses models can be integrated with complete and automatic forging lines, that from bar raw material realize finished forged parts.

The tonnage can go from 170 tons up to more than 2.700 tons, to be chosen according to the geometrical shape you want to obtain and of course to the material to be forged.

The applications

The screw presses are used for the realization of parts destined to different application fields including for example, watch cases, parts for sport equipment, for automotive or for biomedical titanium prothesis.

So, it is possible to produce very small parts, such as for example, clothing zipper pullers till to aluminum sport bows of 1 m of length. The parts, produced by this type of machine, are not cored but full.

The screw presses are very used also in the fashion field to realize belt and bag buckles, with brand-specific shape.

In order to understand which model is more suitable to your production needs, all you have to do is to address to Mecolpress sales department. Thanks to the experience gained with years of activity in the hot forging field, we can suggest the most performing machine according to the type of part you want to forge, and it is possible to carry out a test directly at our premises.

The “possessed” screw press

Even when some machineries present complex problems and when it seems that no solutions are possible, Mecolpress thanks to the solid technical skills that have always characterized it, can solve the situation. A specific case is what happened to a customer of ours and to his malfunctioning screw press. Read all the article to discover the details.

Screw press criticalities

Not long ago we were contacted by an Italian company specialized in the production of spades, shovels and other gardening tools. They bought a second-hand screw press from a competitor of ours because they needed to automate the forging line for spades and shovels by means of robots. Unfortunately, immediately from the beginning, some problems of machine malfunctioning were observed.

Indeed, the screw press just after three or four working hours lost capacity of hit till to stop completely and in addiction it consumed excessively the leather belt that had to be replaced even three times per month.

It really seemed to be “possessed by demons” and even who sold the machine could not solve the problem in the first instance, even though the numerous technical interventions that were carried out.

Since they could not repair in no way the machine and thanks to the suggestions of other machines suppliers, the company decided therefore to refer to Mecolpress hoping to find a valid technical support.

Mecolpress intervention

After a first telephone contact, our technician intervened directly on the press and after a first mechanical analysis he decided to dismount the main screw looking for the possible defect inside the machine.

After a half working day our skilled technician could identify the problem: one of the bronze ring was built with a wrong tolerance and as a result it caused an increase of temperature in the screw. Therefore, the materials expanded and led to a complete stop of the machine.

Our competitors could not even suppose this problem, while our technician in just a working day could identify exactly the reason of the malfunctioning.

This case study has shown how much it is important to have available all the projects and all the technical specifications of the machines which you want to operate on. The bronze ring of the screw press was realized according to a superficial mechanical analysis and to an insufficient knowledge of the complete design of the machinery.

Mecolpress has proved to have the necessary skills and experience to evaluate when a detail can make the difference. Indeed, even some unimportant details can cover a fundamental role in the optimal functioning of a press.

Our company has revealed once again to be a reliable and expert partner you can refer to for complex and apparently insurmountable technical matter.

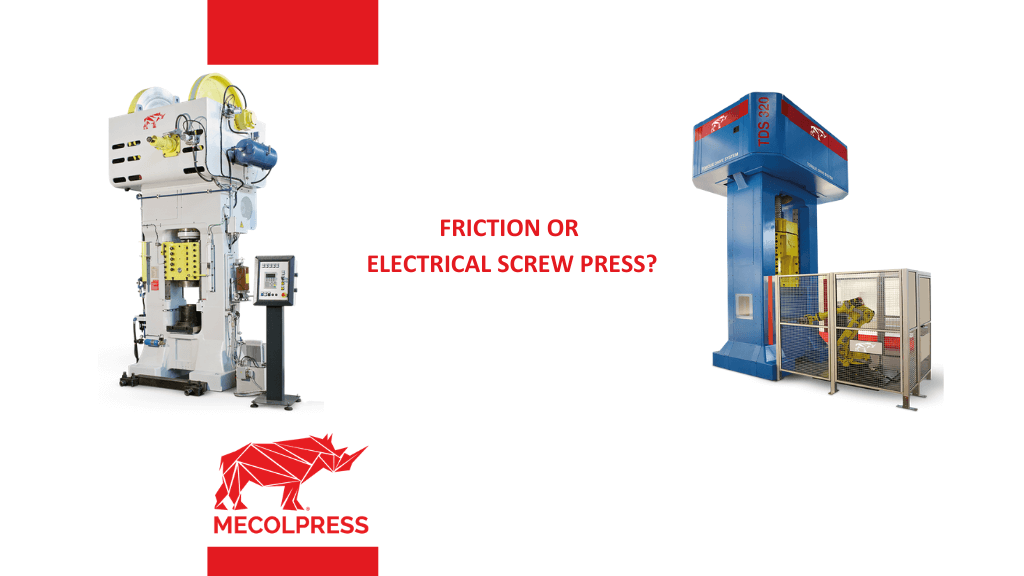

Friction or electrical screw press?

There are electrical or friction screw presses. Which to choose? The choice of the model is linked to the type of parts you want to forge, but also to the press performance. Discover the differences between these types of screw press by reading this article.

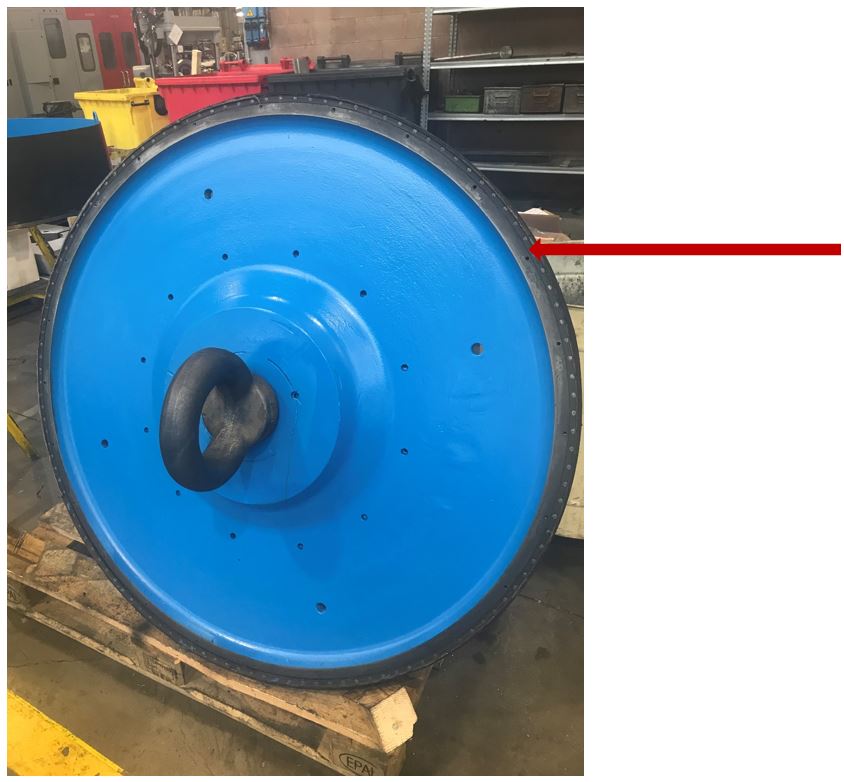

The mechanic friction machine is provided with a flywheel that rotates the screws clockwise or counterclockwise so that to let the slide go down or go up. In this case the transmission of the motion from the electric motor to the flywheel happens through the friction created on a leather belt. This model does not permit a direct control of the motor and of the flywheel, even if it presents considerable advantages in terms of energy saving. Indeed, a friction screw press has a medium consumption of about 40 KWh.

These presses require a smaller investment than the one of the screw presses with electrical servomotor, but they need the leather belt replacement, necessary for the slide movement when it wears.

Suitable for the hot forging of every type of material, the friction screw presses are used for the production of full parts.

This press, as opposed to the friction one differs for an electrical motor directly mounted on the flywheel, in the upper side of the machine, that rotates the screw. Thanks to this characteristic, the electrical screw press allows a better control of the productive process. Indeed, it is possible to check the descent and rise speed at any moment, to have direct feedback about the production of the machine and to calculate the necessary tonnage for the hot forging of parts you want to produce.

The electrical screw press requires more electrical energy, but its components wear less, and it is particularly indicated for the production of parts that require more strokes to be completed. In addition, it is possible to obtain much more energy with a reduced stroke, which does not always happen in the case of friction screw press. As a result, this machine has a rate of production slightly higher than a traditional machine.

The mechanical screw presses of Mecolpress TDS series are moreover provided with Calipso software, which is also developed by our company, that allows the data collection and recording in real time. In this way the end-user can do a process evaluation and intervene to optimize it.

Mecolpress proposes to its customers both friction screw presses and direct control with electrical servomotor control screw presses, developed to satisfy the different productive needs and suitable for the forging of full parts destined to sectors such as automotive, medical and sport one.