Training courses for hot forging

Starting from an inner necessity, Mecolpress has extended the training courses specific for hot forging machineries as a high-quality service against payment that can be offered to its customer companies.

Thanks to the course, it is possible to optimize the production and to improve machines maintenance.

The training value according to Mecolpress

Training is very important, especially in an even more complex productive context and in an even more competitive market. That’s why Mecolpress has felt the need to avail itself of the experience of a hot forging specialist to organize an inner training course of high level.

Understanding the world our customers operate in and learning the art of forging in the best way has always been our priority: therefore, we addressed to Riccardo Segreto that in this interview shared with us very useful suggestions and advanced technical information.

Una volta conclusa questa esperienza molto positiva all’interno della nostra azienda abbiamo quindi deciso di offrire questo servizio di alta formazione anche ai nostri clienti.

Advantages of training courses against payment

Training courses represents a very important instrument for the companies that deal with hot forging, because they offer to people who operate with mechanical and hydraulic presses very concrete and deepened indications regarding how to use them in the best way and to optimize the production.

Today it is not easy to find forging specialists that are available to teach trade secrets. Riccardo Segreto is an independent and very skilled figure, available to share with the companies useful suggestions in order not to wear the press or the die and to improve therefore the productive capacity.

Therefore, a highly qualified staff will be able to carry out some maintenance operations in complete autonomy on machineries for hot forging without the need of Mecolpress customer care service against payment. A correct use of the machine brings therefore to lesser damages and a reduction of machine stops that have a big effect on the production and then on the costs to support.

Our training courses against payment are custom-made developed according to customer’s needs and aimed to the types of presses present in the factory of the company that asked for training. Moreover, they provide an in-depth analysis of the parts to be forged and indications on how to forge them in the best way.

Thanks to our specialist, for example, it is possible to learn how to carry out in the best way the die lubrication and therefore how to prevent its wear and how to adjust the machine stroke. Working correctly with the press has as a result a considerable decrease of costs for our customer companies and that’s why we are firmly convinced that our training courses can represent an added value.

According to companies necessities, the courses can be held at our or customer premises and these have a duration of one or two days, according to the specific program.

Should you need further information regarding training courses, you just have to contact our sales department, sending an e-mail to sales@mecolpress.com.

Courses can be requested both by Mecolpress customer and companies dealing with hot forging that have the necessity to examine in depth some themes.

Optimize the production with Mecolpress training courses

Mecolpress makes available to its customers a training service against payment whose aim is to provide useful information to the staff in charge of the presses in order to use the machines in the best performing way and to optimize the production.

Read this article to discover how training could help a customer of ours to reduce of 50% the maintenance interventions.

The problems of customer Alfa

Time ago a customer of ours, that we will name Alfa, contacted us because of his interest in custom-made training courses for forging machines proposed by Mecolpress. The reasons why he decided to activate the course were several.

First of all, the company employees were not adequately trained and could not use the forging machines in the best way. This implicated a frequent request of assistance from Mecolpress by the customer, and even if our intervention was very prompt, the company had to face up to the interruption of the productive process and to the additional costs connected to the customer care service.

In addition, the company hired new young but still not-expert personnel, however definitely open to technologic innovations and able to use the informatic devices of production machineries.

By their side there was also experienced personnel, working in the company for many years, with greater familiarity with forging techniques, but with some difficulties to approach their selves to the new digital techniques. Persuading them to change method was not so easy, because the long experience matured during years with their procedures.

In closing, the Alfa customer has at his disposal a various set of machines including dated presses, trimming presses, mechanical presses and a new hydraulic press, just bought.

For all these reasons, our customer has felt the need to take advantage of a new custom-made training course that can teach to the operators how to use the machines in the most performing way and to obtain the maximum output with minimum effort.

Mecolpress training course

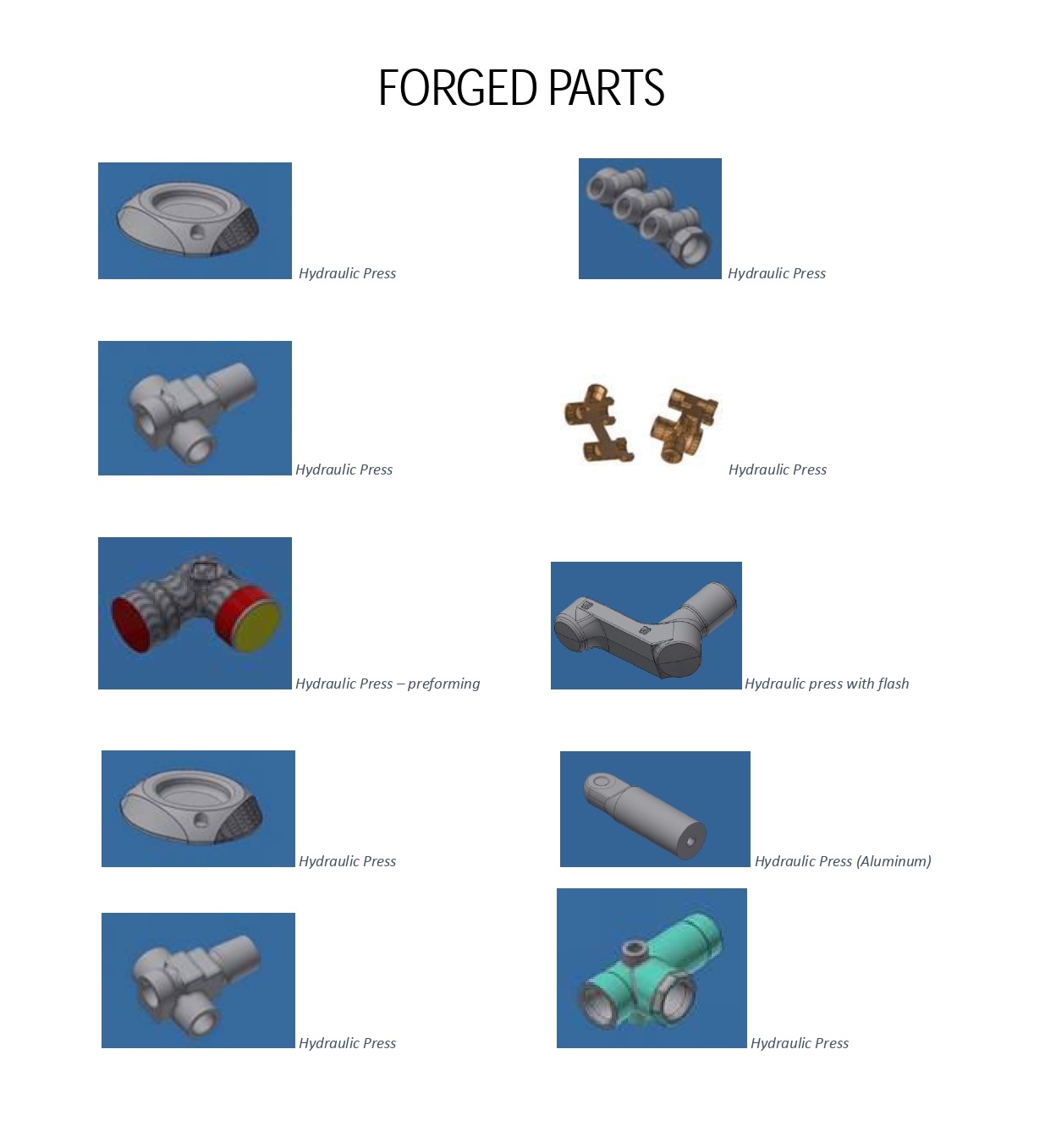

According to the needs expressed by our customers we have planned a custom-made training course that takes account of forging machines in the company and of the type of forged parts.

The course is structured as follows:

- Introduction to hot forging;

- Explanation of drawings and simulation program in support of parts to be forged;

- Parts forging in the factory with an entirely devoted machine;

- Answers to questions of the personnel, detailed studies and explanations on problems regarding the production.

In particular, during the course very relevant matters were debated, such as die and process preliminary analysis, setting of specific parameters, driven setting of the hydraulic presses for parts with flash and without flash and analysis of output with simulations.

Result of the course

Our customer was particularly satisfied with our custom-made training course because of the obtained result.

Indeed, the personnel could acquire an increased competence regarding hot forging, both generally and specific, related to the company production type.

Moreover, the course has contributed to reinforce the team spirit among employees, that is of high importance to create a working environment based on collaboration. Indeed, activities of this kind contribute the personnel to interact more, to better work as a team and also to better face with the daily difficulties.

After our training our customer has decreased drastically the number of service requests against payment. Indeed, the operators in charge of machines can now use better the presses with a lesser wear and they can carry out in autonomy some activities of ordinary maintenance, without the need of Mecolpress technicians.

For further information about Mecolpress training courses, please send an e-mail to: sales@mecolpress.com.