EXHIBITIONS 2022: MECOLPRESS AT CASTFORGE (GERMANY)

CastForge 2022

Castforge Exhibition from 21 to 23 June in Stuttgart.

Today costumers of the “Casting and Forging” field are looking for high-quality products ready for installation. As complexity and specific requests are constantly increasing, it is essential to stay on top with the latest news.

This Exhibition represents an important opportunity to meet face to face and discuss these topics in one of the largest markets in Europe.

For this reason, from 21 to 23 June 2022 Mecolpress will be in Stuttgart at Castforge (Stand 5B57).

Augmented Reality, the press just a click away

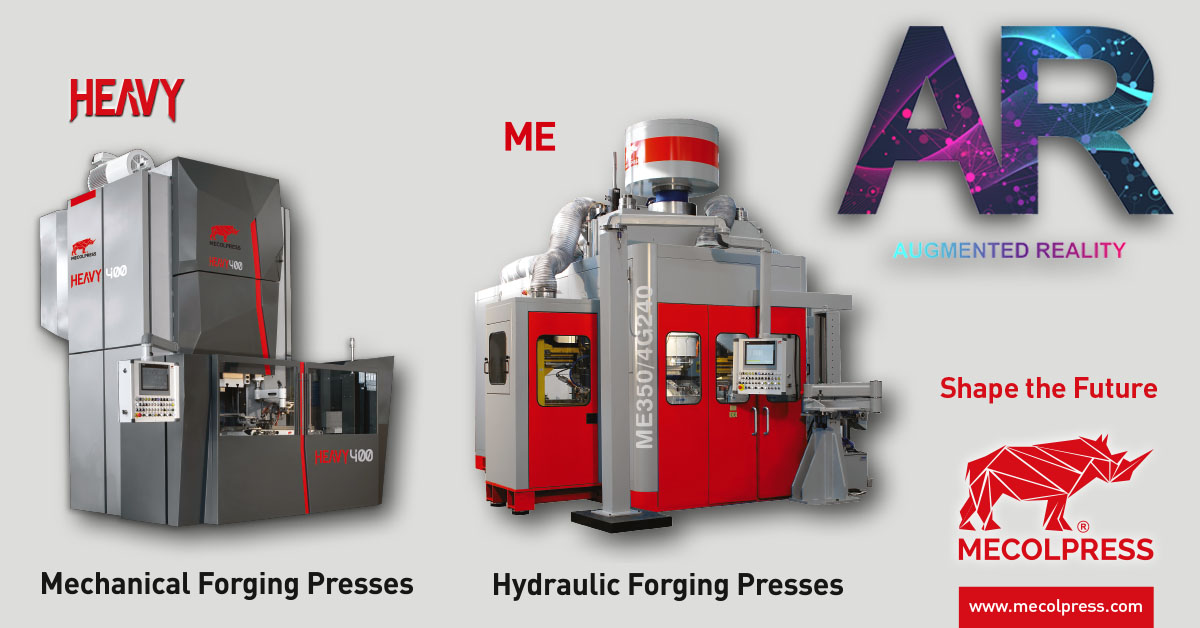

On our stand it will be possible to view 2 Augmented Reality presses: ME hydraulic press and Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

EXHIBITIONS 2022: MECOLPRESS AT BIEMH (Spain)

BIEMH Bilbao 2022

This event will be held at the Bilbao exhibition centre from 13 to 17 June 2022.

Mecolpress will present its latest technological innovations regarding metal forging.

Besides Spanish companies also international ones will be participating in this event, operating in sectors such as: metallurgy, welding, articles and equipment, machine tools, technological solutions, and much more.

You can find us in Pavilion n°5 Stand D34

Augmented Reality, the press just a click away

On our stand it will be possible to view 2 Augmented Reality presses: ME hydraulic press and Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

Exhibitions 2022: Mecolpress at GLOBAL INDUSTRIE (France)

Global Industrie Paris 2022

In three editions, Global Industrie has established itself as one of the leading exhibitions in the world dedicated to industry.

Its resolutely modern positioning geared both to the industry of the future and to international business explains the success encountered by its previous editions held in even years in Paris and odd years in Lyon. A geographical diversification which enables it to enhance both its offer and the variety of its visitors.

Global Industrie returns to the capital from the 17th to the 20th of May, at Paris Nord Villepinte.

We are waiting for you Stand 6M91

Augmented Reality, the press just a click away

On our stand it will be possible to view 2 Augmented Reality presses: ME hydraulic press and Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free admission ticket

To facilitate the visit and access safely, it is advisable to register to get the free admission ticket.

You can request it by simply filling out this form:

HYDRAULIC PRESS, Mecolpress leap into a new eco-green modality

Main features of the new ME eco-green Hydraulic Press

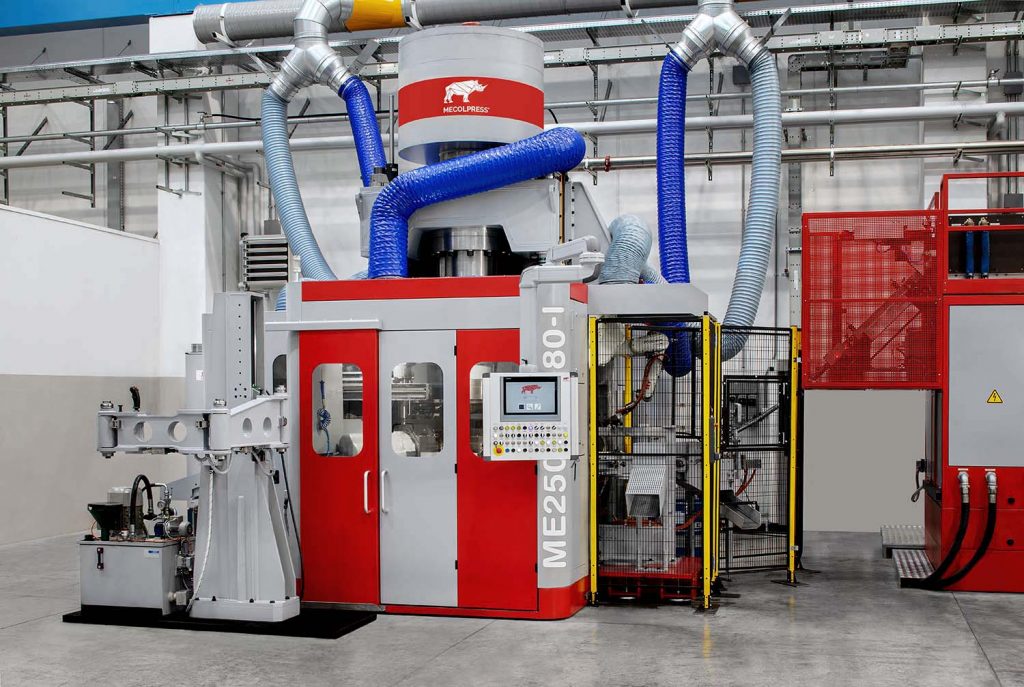

Mecolpress S.p.a. is glad to introduce the new improved features of ME family hydraulic presses, born from the need to offer to the Customers a more flexible and performing machine in terms of product quality and energetic consumptions.

We are currently proposing the family of ME presses having the die closure force that is in the range from 100 to 500 tons (as standard equipment) and with a minimum side punches force of 30 tons that can achieve up to 350 tons. Each of these last ones has completely independent operation, adjustable speed and set-able movement phases (forward-stop-backward); depending by the type of part to be forged , the hydraulic closure cylinder allows to apply the necessary forging force also before the dies contact.

The new presses can be fed by one anthropomorphic robot for the billets loading and one synchronized unloading arm for the forged products that eliminate the set up difficulties of the traditional past technologies; regarding the fumes suction, after a careful analysis of the actual state of the art, we have implemented and optimized the system making it more functional and effective.

The fume suction hood collects the emission very close to the sourcing point decreasing any possible spread into the press cabin, granting to the operators the best inside view of the process and reducing the oil collection and its possible overflow.

In this regard, the machines of the new series are integrated with the walkable grids that surround the press and prevents the eventual drip on the floor of the working area.

The hydraulic presses can be supplied customized with optional equipment according to the production needs.

For example, one of the punches can be oriented with the coring angle that is different from the classic 90° configuration , allowing in this way the realization of particularly complex shapes, like y-joint or filter body.

Other possible configurations are of new ME eco-green Hydraulic Press are:

- the addition of a fifth vertical punch acting from under the die,

- the loading of one or two billets at the same time up to a maximum of four,

- the addition of a dies-holder arm lightening the machine tooling process,

- the addition of a quick dies changing system with hydraulic locking,

- the addition of an induction dies heating system which the machine is particularly compatible with,

- fire extinguishing system integrable with the machine.

Moreover the main innovation is related to the energy saving achievements if compared to the previous series.

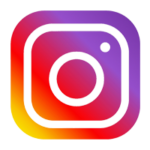

From 2022 all the ME presses can minimize autonomously the energy amount that is needed to produce the desired forged part: the press learns automatically the optimal pressure to be addressed to each forging punch: ECO cycle (settable from the control panel). Furthermore, during the movement of each forging punch, Calipso control software optimizes the time in which it is necessary to switch to the maximum achievable pressure (regenerative self-adapting cycle function): all the press parameters will be consequently harmonized according to this requirement.

This behavior represents the key economic and competitive advantage for the press user that can save up to 50% of the total installed energy without losing or reducing the punches force and can optimize the forging process parameters in order to minimize the energetic consumptions. To do this the operator direct intervention is no longer necessary. The operator is not required to have a long term experience or particular skills : he will simply have to activate the ECO cycle from the control panel, ME press will care of the rest!

he will simply have to activate the ECO cycle from the control panel, ME press will care of the rest!

Discover Mecolpress

“𝗗𝗶𝘀𝗰𝗼𝘃𝗲𝗿 𝗠𝗲𝗰𝗼𝗹𝗽𝗿𝗲𝘀𝘀”:

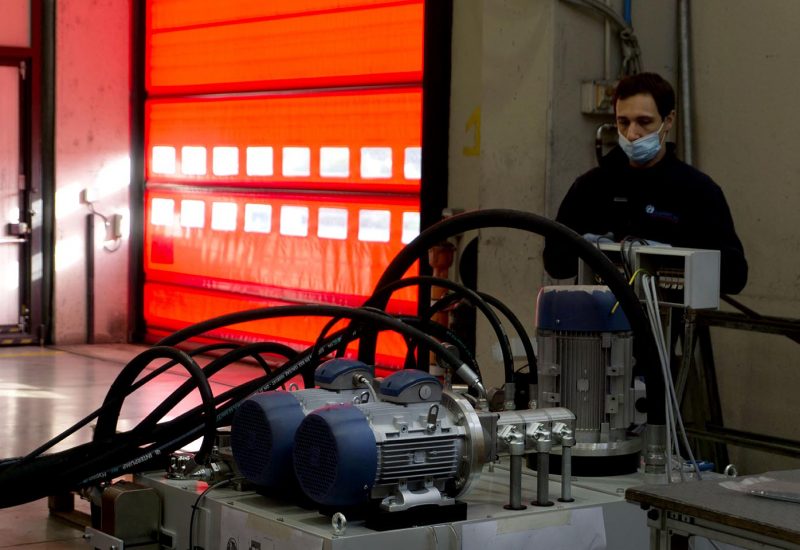

Discovering Mecolpress: a journey through backstage pictures.

With some pictures “caught here and there” and with some related comments we will try to let you know more about our Company.

We will drive you to the discovery of Mecolpress world, about our constant dedication to growth and innovation of hot forging technologies, and how we work hard to guarantee you the best reliability and Customer Care service of all over the world.

Our aim is to use a point of view that is not “stick” or simply related to the ordinary catalogue pictures; we will use the reportage style showing aspects that are usually hidden, but that, according to us, can reveal interesting and valuable peculiarities.

A path that tends to highlight, to reveal that behind the machines, technology and mechanism there are women, men that thanks to their ideas and passion constantly contribute to develop new solutions for the evolution of our products and services.

This is a way to show a “human” aspect of Industry, made not only of aseptic engineering but also of ability, expertise, experience of people who lives daily the company, the productive workshop and the administration/management offices.

Pictures revealing a soul made of personal skill, methods rich in creativity that can be found also in the details of the productive process.

It is also through these initiatives that companies can share aspects, information and pictures that tangibly contribute to the growth and strengthening of the relationship between companies.

BORN WITH HOT FORGING OF BRASS, ENLARGING TO ALUMINIUM AND STEEL: THE VISION OF MECOLPRESS

Read the Corriere della Sera special dedicated to the metallurgical industry. This article talks about the vision of Mecolpress as a supplier and manufacturer of hot forging machinery. Click here:

METALLURGICAL INDUSTRY THE EXCELLENCE OF MADE IN ITALY

BORN WITH HOT FORGING OF BRASS, ENLARGING TO ALUMINIUM AND STEEL: THE VISION OF MECOLPRESS

… as undisputed leader in the production of hot forging presses for brass components, in recent years we added the focus on technologies for steel and aluminum applications.

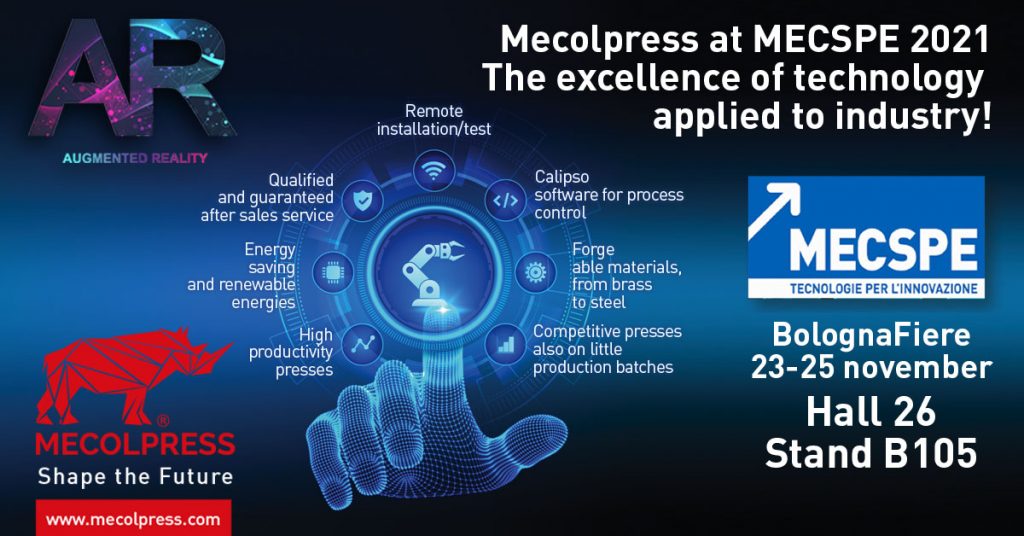

MECOLPRESS AT MECSPE 2021

THE EXCELLENCE OF TECHNOLOGY APPLIED TO INDUSTRY

It has been the most important event dedicated to innovations for the manufacturing industry and it counts 19 editions.

The fair will be held in Bologna from 23 to 25 November.

MECSPE, the main event in Italy on innovative technologies for manufacturing 4.0 industry promoted by Senaf, joins this outlook of restart and business confidence by following its commitment to support this sector and representing itself for 19 editions of over 2,300 exhibitors and trade associations.

This year’s appointment, rescheduled at BolognaFiere, from 23 to 25 November 2021, will have as its main theme “digitalization, training and sustainability”, subjects that visitors will be able to explore through 13 synergistic salons divided by thematic areas, demonstration of talent, commitment and creativity of Italian Companies.

A field, the industrial one, has always been supported by MECSPE which promotes fruitful collaborations between the various players in the supply chain, sharing visions and projects with them, as demonstrated by the historic partnerships with Confartigianato Meccanica and CNA Produzione.

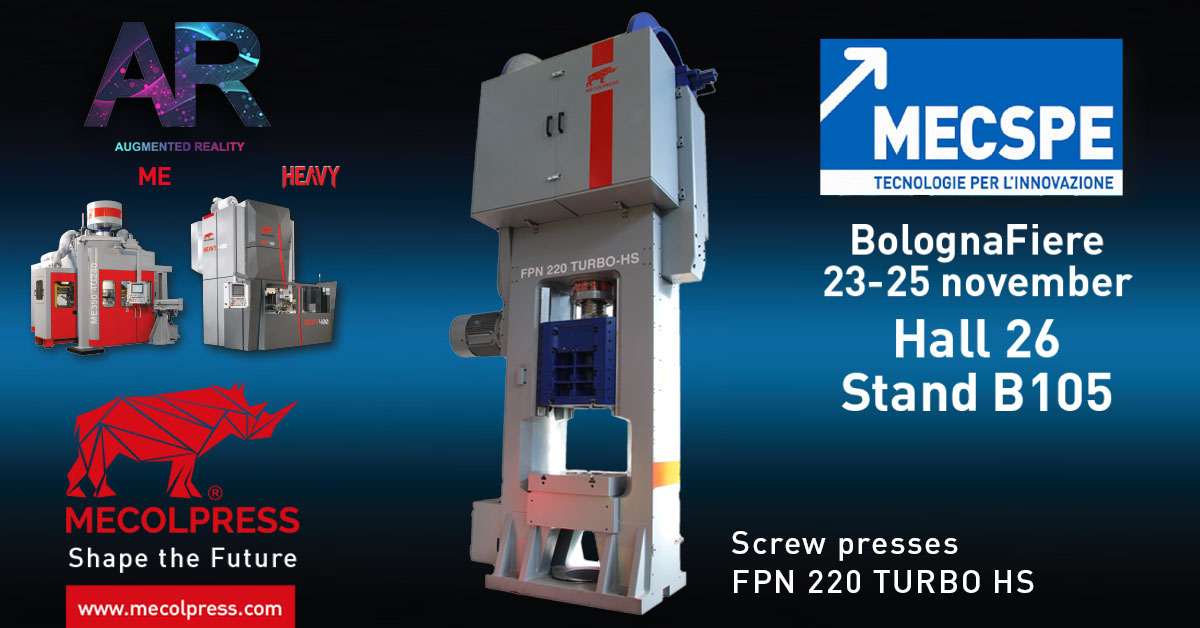

At MECSPE 2021 we will exhibit the FPN 220 Turbo HS screw press.

This is the best evidence of the outstanding performances of the OSTERWALDER screw presses, part of by Mecolpress family from more than 20 years.

These screw presses are particularly suitable for processes where high precision\tight tolerances of forged components are required, for example in the production of gears. They are suitable for hot forging of steel parts, but also of all other materials.

The TURBO version allows to reach higher speed, increasing productivity from 20% to 40%.

Augmented Reality, the press just a click away

In addition to the FPN Turbo screw press, it will be possible to view two other technologies thanks to the Augmented Reality: the ME Hydraulic and the Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free admission ticket

To facilitate the visit and access safely, it is advisable to register to get the free admission ticket.

You can request it by simply filling out this form:

ForEMOst!

ForEMOst!

EMO is the worldwide exhibition of the machine tool, held in Italy and Germany, and that this year will take place in Milan at Fiera Milano Rho from the 4th to the 9th of October.

All the main international players of the manufacturing sector will take part in EMO MILANO 2021; so far there are more than 30 countries represented, covering all the segments that make up the world of the metalworking machines.

Undisputed leader in the trade fairs panorama, EMO represents the whole metalworking world in the best way, showing the best of vision and innovation.

Metal forming and metal cutting machine tools, robots, enabling technologies and automation, solutions for interconnected and digital factories, additive manufacturing will be among the key players of EMO MILANO 2021.

The exhibit is held in the entire Fieramilano Rho Exhibition centre, that can be easily reached with any transport means.

To guarantee visitors and exhibitors the participation in total safety in the exhibition, Fiera Milano Group has developed a Protocol for the safe conduct of trade fairs, in full compliance with the health rules and protocols issued at national level.

MECOLPRESS will participate with a “revolution” of the exhibition concept

Augmented Reality, the press just a click away

This technology allows to overlap multimedia information to the reality framed by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

A very powerful mean in the company communication field, and in this regard, the Augmented Reality has a strong impact on the customer experience, because it transforms the way in which companies interact with their customers.

In the trade fairs the Augmented Reality results to be very useful, both for the exhibitors and for the visitors who will be able to live a visual experience at 360-degrees.

Two will be the presses, chosen from the production range of MECOLPRESS, that will give birth to this innovative space of virtual reality, that will offer the possibility to see and to experience the functionalities of the represented machines.

We are waiting for you Hall 5 – Stand B29

Get your free admission ticket

To facilitate the visit and access safely, it is advisable to register to get the free admission ticket.

You can request it by simply filling out this form:

MECOLPRESS: THIRD GENERATION TO GROW AND IMPROVE EVEN MORE

Read the special “Giornale di Brescia” dedicated to Mecolpress, click here:

Mecolpress Special Edition June 4th

The technology and the strategies to win the challenge

Click on image for the English version of the article:

The change is a constant in our lives and for Mecolpress, for more than 50 years, it is seen as an opportunity.

That’s how that the best projects and products are born and developed.

Shape the Future!

#MECOLPRESSCHRISTMAS2020

Usually in Mecolpress, to celebrate Christmas, we express each other good wishes with two special events: a dine-out evening that allows us to share special moments, stories and anecdotes, and a toast in production on the last day of work accompanied by the speech of our president.

This year obviously it will not be possible to do any of this, so what?!?!

What can we say about 2020 coming to an end?

Certainly the year we are leaving behind is a year that we will remember because of Covid that has not spared any country in the world.

If we are to talk only about the Mecolpress reality, we can now consider ourselves lucky in terms of health. And also from a work point of view the year is ending without major deviations from the previous year even if we had foreseen a very aggressive budget that aimed to different results, we can say that the current situation caused by Covid has not put us in particular difficulties as may have happened for other types of companies or other production sectors.

This year it was not possible to carry out some technical interventions in some countries, all the trade fairs to which we were registered could not take place, and we had to postpone visits to our mainly foreign customers.

But we’ve all learned to use more digital tools, which allow us to meet remotely.

We have even tested entire forging lines remotely, and more and more customers have chosen to use our calipso software for forging control.

But above all we had the opportunity to verify with pleasure and satisfaction, that our customers from all over the world (some even newly acquired!) have renewed their confidence despite the physical distance.

What interesting news we have implemented internally in 2020?

Speaking instead of the Mecolpress reality inside we can say that we have finished most of the works planned in the new Shed 5, specifically the most interesting thing we implemented was the purchase and starting up of a powerful induction oven. This oven is for our exclusive internal use and allows us to perform forging tests not only for brass and aluminum pieces, but also for steel pieces. Steel in fact needs higher temperatures than other materials. Thanks to the work that our technical engineer specialized in hot steel forging is doing, we are investing a lot in the production of machines for this material.

We realize more and more that for the customer to have the proof, to see the piece to must be forged, concretely made by a machine that we always have available to carry out forging tests, is very important!

Often customers come to us who have to make even complex pieces, with many doubts and perplexities. It is of great satisfaction for us to show them how the Mecolpress press that we recommend to them, after study by our technical office that also uses a forging simulation, can make their piece with higher quality requirements. And it’s that added quid that has often allowed us to make a difference.

What we expect in 2021?

The spread of Covid-19 obviously weighs on any forecast or programming. But we hope to reschedule many businesses that have been postponed in 2020. We are currently investigating global markets to assess how much customers will be able to invest in the coming months.

However, we are full of preparation and positivity, our sales force is working to propose solutions suitable for needs that may be changing.

And above all we are on the piece!

Mecolpress Best Wishes

Since it is not possible to exchange greetings as usual, we just have to do them online, but with our hearts. We sincerely hope you can spend a serene Festivities, this is the wish we address as well to our employees and their families, our customers and collaborators.

Because Mecolpress is made by all of you, of people who work every day, collaborate, give us confidence and make Mecolpress not only a company but a large family.

In this regard we ask you to share with us selfies, a wish, a phrase, or a toast … to share the wishes with us, DISTANT BUT UNITED:

Post your message on the social networks and mention @mecolpress

Insert the hashtag #MecolpressChristmas2020 #WeAreOnThePiece

Our social channels: