Remote forging test

Case study: remote forging test for the acceptance of an entire line

A few weeks ago we carried out a forging test completely on-line.

Generally, it’s the customer who comes to Mecolpress site and follows all the agreed forging tests, the complete development of the necessary activities and the forging phases of the agreed parts.

For the customer this means in any case to travel, physically being absent for some days from the office and personal business, incurring more or less important costs … in conclusion facing challenges weighed down by the situation that has developed because of Covid-19.

In order to meet the need of our customer we have ensured that the forging test for the acceptance of the entire line, that has as cornerstone our ME350 hydraulic press, was carried out totally on-line.

Therefore, we proceeded this way:

- The customer installs a software indicated by Mecolpress for a safe and certificated VPN connection.

- In this way a connection between customer internet and the press located in Mecolpress is established.

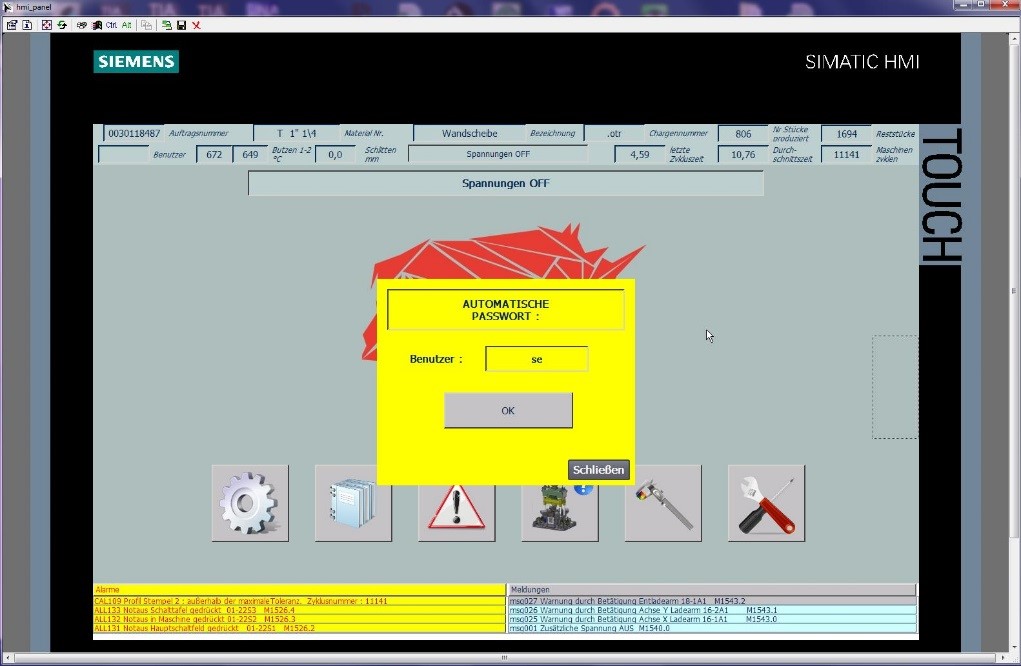

- Now the customer can access directly the machine operator panel.

4. We installed 2 video cameras, reachable by means of ip-adress, running for the whole production duration. The customer can follow the video live from any PCs.

5. Always only inside the established VPN it is possible to access through browser to the two cameras that are always on during the entire forging phase.

6. A technical support representative in Mecolpress is always and in any case available by telephone.

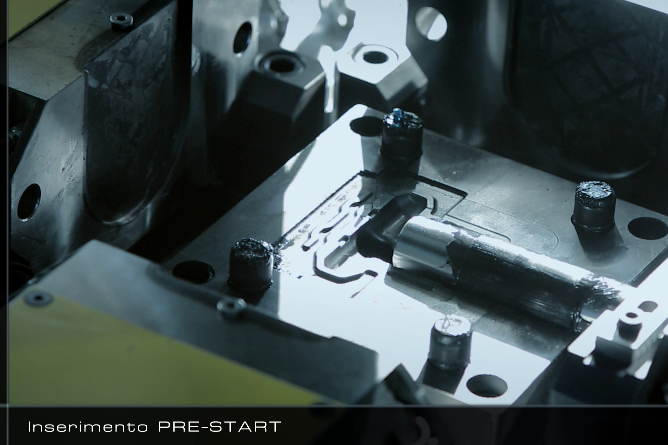

7. All the procedures regarding the setup phase and in particular the die changing phase are visible.

8. All the videos and pictures are therefore strictly confidential and visible from a webcam only to the customer that can save videos, if he considers it appropriate, or taking some pictures, everything always with the maximum confidentiality.

Which have been the advantages for our customer?

The advantages resulting from this acceptance-from-remote procedure of an entire hot forging line are easily identifiable:

- Time-saving,

- Costs-saving,

- Possibility that more people can follow the forging test, comfortably in front of a PC.

New procedures for remote tests

These methods of digital implementations are fundamental, but we still believe that in the world of precision mechanics and capital goods, the aspect of customer consultation is crucial and that as a result the personal contact is still necessary to carry out efficient projects according to partnership optics with the customer and to a deep understanding of his necessities.

Anyway, it is important to offer to our customers the alternative of remote forging tests. The customer experience is however total: video connections, real time data extraction, possibility to access to the press panel.

This procedure can bring also to future developments, for example, let’s think about how it can be useful if it would be set up on the contrary: a Mecolpress technician could have all the useful tools for diagnosing a problem on a machine located in Australia and solve it immediately! Without taking the plane, without taking a long journey, without charging important costs to the customers, avoiding long machine stops.

HOT FORGING PRESSES INTERVIEW WITH MECOLPRESS

Company manufacturing hot forging presses.

We report an interview of the digital magazine Easy Engineering of 28 April 2020.

Established in 1969, MECOLPRESS was founded as a manufacturing company of mechanical presses for brass components hot forging. Up to today, Mecolpress has developed and installed more than 1.950 presses, at over 400 customers all around the world, used for forging brass, aluminum, copper, titanium, steel. The current production site in Flero, in the highly productive area of Brescia, takes up a 30.000 square meters surface, 10.400 of them are covered and employees 55 people, reaching a turnover in 2018 of 11.5 million Euro.

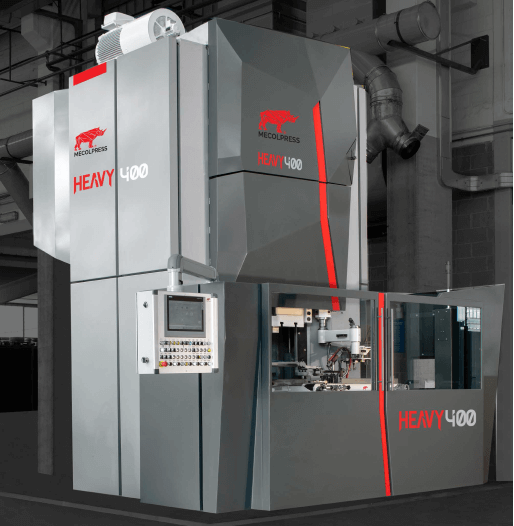

In 2019, in occasion of EMO exhibition in Hannover, Mecolpress officially presented the new series of continuous and discontinuous cycle eccentric presses, the HEAVY series.

Easy Engineering: What are the main areas of activity of the company?

MECOLPRESS: At the beginning all efforts were concentrated on brass hot forging field; in the time, also through the acquisition of the historical brands Osterwalder and Dellavia in the screw presses section, the variety of machines that we design and produce is now so wide and complete to satisfy the most different requirements of the customers: for each specific material, shape and quantity to be forged, we are in the position to offer the most suitable solution.

Mecolpress is today the only company among the manufacturers of presses for the hot forging of brass, aluminum steel, copper, titanium, with a so complete production program.

Our present production program consists of:

- TDS: direct drive with electrical servomotor;

- Dellavia and Osterwalder: Traditional disc friction.

PG Knuckle joint presses

for calibration and coining of parts.

Presse Meccaniche Eccentriche

- SOV and SEO/F: for the vertical hot forging;

- SEO and HEAVY: for forging with horizontal cores, in single or continuous cycle.

for forging brass and aluminum parts without flash.

- PO: single station;

- S: multiple station, rotary table with hydraulic motor;

- E: multiple station, rotary table with electric motor.

In addition, Mecolpress is particularly active in after-sales service. The heart and pride of Mecolpress is its large spare parts warehouse, which is able to supply accessories or spare parts for machines produced fifty years ago. For this reason, in addition to the sale of machinery, there is a wide activity related to the service and supply of accessories (such as tools, arms, spare parts, etc..).

E.E: What’s the news for 2020 about new products?

MECOLPRESS: At the end of 2019 Mecolpress presented at EMO fair in Havvore a brand-new series of eccentric presses, named HEAVY, which defines a new standard for the hot forging of brass.

A machine concept that offer highest durability and reliability together with an innovative software system that allows the maximum control on the process and the a very easy operation.

E.E: What are the ranges of traded products?

MECOLPRESS: As a manufacturer with an own wide range of products, the additional equipment that we simply trade is limited to ancillary machines, to offer complete forging lines (delivering a finished part from the input of a raw material bar) to those customer that prefer to have a turn-key plant from one source.

Typical traded machines are: billets heating furnaces, forging dies, sand blasting machines.

E.E: At what stage is the market where you are currently active?

MECOLPRESS: Since our machines are dedicated to a very wide panorama of applications (from house building to automotive, from gas control to biomedical) there are always new developments in these sectors.

This is for us very stimulating because we are constantly involved in the design of new solution, to support our customers with the most suitable equipment to manufacture parts that are chancing in the shapes, in the alloys and in the technical requirements.

E.E: What can you tell us about market trends?

MECOLPRESS: In the past our customers were mainly subcontractors, producing many different kinds of parts for the most differentiated OEMs. We see now more and more companies that are interested in bringing back into their own activity the hot forging process, to have full control over the entire production line. And also, the subcontractors that still exists, are increasing in size, in capability, and in specialization: they are requested to be much more accurate, reliable, more flexible and fast in changing production and technologies.

For these reasons, the machines that both our customer types (the subcontractors and the OEMs) need, are machines that can easily switch from one application to the next, and that can record and control really in depth every aspect of the production process. The user is therefore becoming more an engineer, that study and program the process in advance and then let the machine run autonomously, instead of an operator that has to stay full time at the machine, checking and adjusting the settings.

E.E: What are the most innovative products marketed?

MECOLPRESS: As above indicated, one of the most innovative products that we offer today is the new range of Heavy presses.

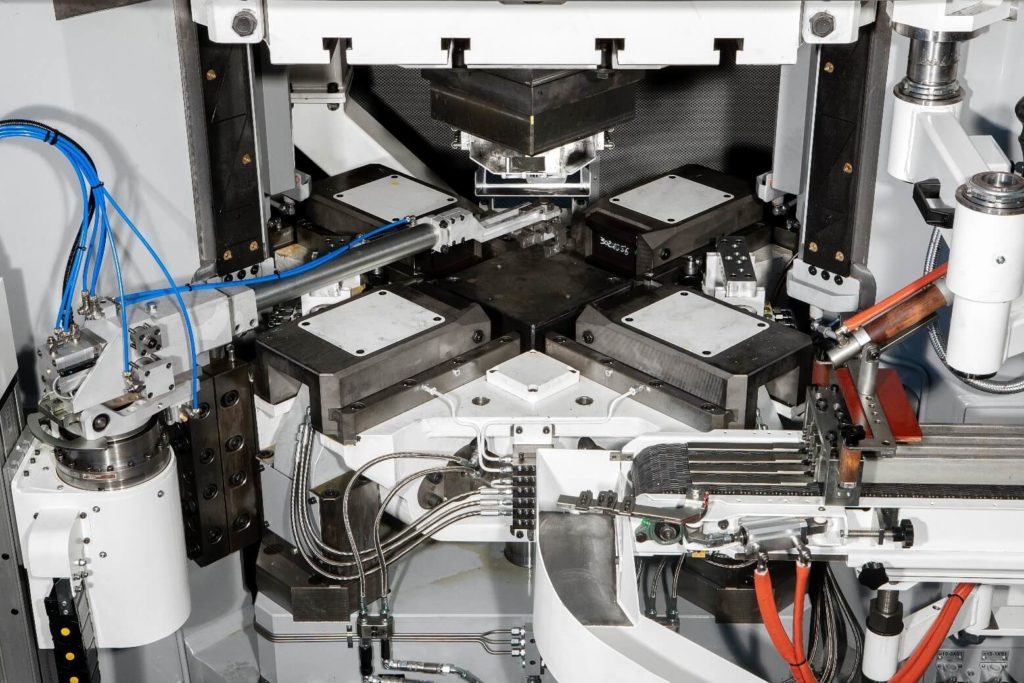

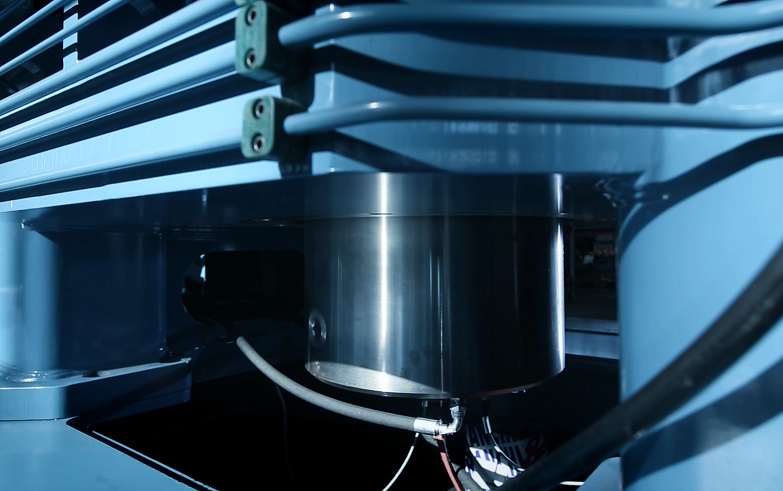

In parallel to this, we are widening the offer for the ME hydraulic presses which are designed to forge net shape parts. These machines are extremely versatile, can communicate in two directions with the company ERP software to exchange production data, recipes, preventive maintenance information. And are also able to automatically detect a non-conforming product and separate it from the good ones. This makes the ME forging presses a fully automatic system, that does not require operators to work but also does not need regular presence of quality control staff to check periodically the output.

E.E: What estimations do you have for 2020?

MECOLPRESS: At the end of 2019 we planned a very aggressive budget of sales for the 2020, and supported it with several activities and strategies, from the participation to many international shows, to the production of machines for stock, to grant to our customer very fast deliveries.

Unfortunately, due to the Covid-19 virus spreading, many commercial activities had to be reprogrammed or postponed. We are now investigating the world markets to assess what will be the customers’ propensity to invest for the remaining months of this year. We are very optimistic that we will in any case be able to reach most of our targets also thank to the availability of machines in our workshop, which is allowing us to complete deliveries in this year of machines ordered in the second and third quarter.

Another company based in Brescia chooses Mecolpress hydraulic presses.

With regularity and continuity, Mecolpress gains new Italian customers, the hydraulic press is confirming to be the winning choice.

Case Study: How we acquired the latest customer from Brescia

We report the case of a new customer based in Brescia that we have just acquired, an interesting case study to understand which are the necessities of the companies working in the hot forging sector and how Mecolpress provides answers.

It is the case of a company established in the international market for the very high quality of its production, consisting mainly of mini valves, valves and fittings for the sanitary and heating sector. This company has its own brass hot forging department, developed to cover the 100% of the forged parts needs; the recourse to very few and highly selected external suppliers happens just in case of particular peak of volumes.

The presses equipment of this company consists of 5 machines, always full of work: 3 more traditional and “dated” (eccentric mechanical presses of the historic producer Rovetta, that now no longer exists) and two more recent little hydraulic presses of a particular type, proposed by an European producer.

Knowing better the company, now customer of us, we could appreciate right from the beginning some undisputed features:

- Advanced transfer machines;

- A working method focused on the precise and deep knowledge of all the productive processes;

- A forward-looking vision on the continuous training of all the personnel that is involved with the management regarding the strategic decisions and that creates a uniform a close-knit group;

- A quality department having knowledge, methodologies and instruments not only for the examination of the parts but also for the evaluation of the method used for their production.

During various meeting both at customer’s and Mecolpress site, we had the opportunity to present them our complete range of presses and in particular the functionalities of our hydraulic presses of ME series.

Mecolpress method

The customer wanted to test us, taking advantage of the Mecolpress strategy of having a selection of presses almost ready for delivery, for carrying out forging simulations with two parts of their production range on the specific press of their interest.

The result was that, thanks to the constructive collaboration of both teams (the customer and the Mecolpress ones), in just 9 weeks from the decision of beginning with the simulations, we could:

- Carry out the forging simulations of the two parts to be tested;

- Manufacture the related forging dies;

- Carry out forging tests with two dies (in manual and in automatic cycle, since Mecolpress has 2 high-performing push-type gas furnaces;

- Dismantle and demolish one of the old presses of the Customer;

- Deliver at customer site in Brescia a new ME150/4G62 hydraulic press, exactly the same one the customer saw and tried.

Why the company under consideration chose Mecolpress?

We thank the customer for the trust and for having tested us, and we are particularly proud that even they, as other customers, after having bought and used the hydraulic presses of our competitors, have chosen to purchase Mecolpress for the future.

The decisive points for this new positive result are in short:

- Mecolpress can offer to the customer not only any kind of new presses, but also exceptional expertise in the maintenance of old presses, of other manufacturers (in this case Rovetta).

- Mecolpress hydraulic presses, both for mechanical and construction project and for extremely developed software, offer to the user an incomparable ease and usage flexibility.

- Choosing Mecolpress, the possibility to conclude an investment in very short time, and to see it becoming rapidly productive; who wants to invest has no time to wait and must be helped to be competitive as soon as possible!

Would you too like to try a forging simulation?

Don’t waste your time,

test us!

STEEL HOT FORGING: THE WORD TO OUR EXPERT

We interviewed Luca Di Donato, Mecolpress specialist for steel hot forging.

Steel is a far different material from brass, for this reason Mecolpress has decided to increase its team with a devoted figure, to whom we have addressed some questions.

Let's talk about steel hot forging

What is your role in Mecolpress?

The role I currently play in the company context is project engineer manager specialized in steel hot forging and non-ferrous alloys (except brass).

Specifically, I mainly deal with the identification and definition of the hot plastic deformation process that is technically and economically most suitable for the production of semi-finished steel components but also aluminium and special nickel and Titanium alloys.

What kind of experience do you have in steel hot forging sector?

The gained background in the specific sector derives from many years of work experience acquired in the company field, initially as a designer and then as technical and operational director of companies located in Italy and abroad.

Which application sectors do usually use steel hot forging presses?

Presses for steel hot forging are widely used in many application sectors such as automotive, aeronautics, agriculture, construction, chemical, petrochemical and industrial sector in general.

Which type of machine is most suitable for steel forging? (mechanical presses, hydraulic presses, screw presses?)

From a metallurgical point of view, steel can be forged using every type of press, since the types of steel in general are little affected by the presses deformation speed as some aluminium alloys and the super alloys of Titanium and Nickel are affected.

Therefore, there are other parameters that influence the choice, in fact the geometry, the geometric and dimensional tolerances can certainly guide the choice on a mechanical press rather than on a screw press, but also on a hydraulic press.

Compared to brass, which are the distinctive traits of steel?

From the process point of view and therefore from the point of view of the relative presses, the first aspect that is typical for steel is certainly the forging temperature which is around 1200 ° C.

The other equally important feature is the steel deformability which is far more difficult than the one of the brass. The resistance to hot plastic deformation of steel forces the adoption of simpler geometries, the adoption of presses with increased capacity in terms of forces, moreover, pre-forming processes are often used.

According to your experience, which are the recurring critical issues that you could observe in the forging of this material?

As previously highlighted, steel is forged at high temperature, therefore possible overheating can be created in areas that are particularly subject to deformation, the involved forces are important and as a result the energy and disposition can approach the limit and cause no geometric conformity on the piece.

In the end, steel cannot be easily deformed and therefore it requires a specific study to understand which preforming processes are better to adopt in order to avoid cracks / folds of material.

Always according to your experience, when we want to choose the most suitable machine, what should we absolutely consider?

Obviously the geometry of the forged product to be obtained, together with the imposed geometric and dimensional tolerances, strongly influences the choice of the best process, first of all the type of press but also all the machines necessary to compose the line, from the cutting, heating, and preforming process up to the possible calibration of hot / cold forging.

Mecolpress, through the specific skills acquired in fifty years of working history and thanks to its professionalism, is able to support the customer from the very first stages of defining the most suitable geometry for the choice of the forging up to the realization of the line, also fully automated, turnkey.

What do you think that can really make the difference in a “guessed” press?

The heart of the production line in its entirety is the PRESS which has been designed to respect specific characteristics, as a result “guessing” the type of press is absolutely important, but it is equally essential to consider who designed and built it, in this regard the presses produced by Mecolpress are considered to be among the best on the market, both in terms of technological content and in terms of rigidity and reliability.

If you want further information regarding the topic “Steel hot forging”, we invite you to consult the U.NI.S.A. Italian National Union of Steel Forgers, of which we are aggregate members.

HEAVY SERIES MECHANICAL PRESSES

Mecolpress, at the EMO exhibition in Hannover which took place last September, officially presented the new series of eccentric continuous cycle mechanical presses, the HEAVY series.

Based on the experience accumulated over 50 years of designing and manufacturing presses for hot forging metal, we have succeeded in creating a totally renewed mechanical press.

We are sure that our new project will mark the beginning of a new era for hot forging!

What are the main strengths of the new HEAVY mechanical presses?

-

- A structure that is certainly innovative and modern, more robust and designed to simplify control and maintenance;

- Fully revised die automation and lubrication;

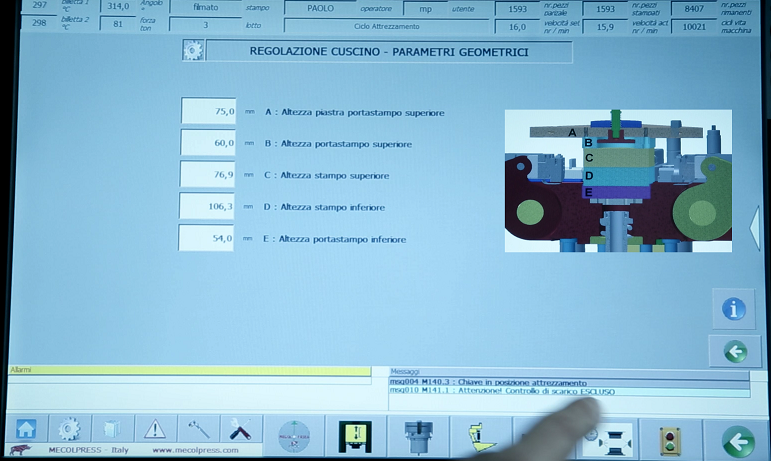

- Our innovative hydraulic cushion, the Soft-Impact, which allows to achieve important results including for example the possibility of vibrations reducing;

- The updated version of our intelligent Calipso software, for the analysis of the production process and for predictive maintenance.

Let's analyse the features in detail:

STRUCTURE

The structure of the machine is made in such a way as to separate the dangerous area (moving parts and die area) from the areas accessible to the operator for adjustments and ordinary maintenance, through front protections and soundproofing material casings, as required by CE standards.

Directly on the vertical part of the forging area, the fume extraction is obtained through metal ducts with connection to the customer’s centralized system.

The control unit for centralized lubrication of the press, the regulators of the pneumatic system and of the die lubrication system and the electrical equipment are inserted in large protected cabinets and easily accessible to the operator, not reached by the fumes and the oil of die lubrication .

The assembly of the main parts to the machine is designed to simplify inspection and maintenance.

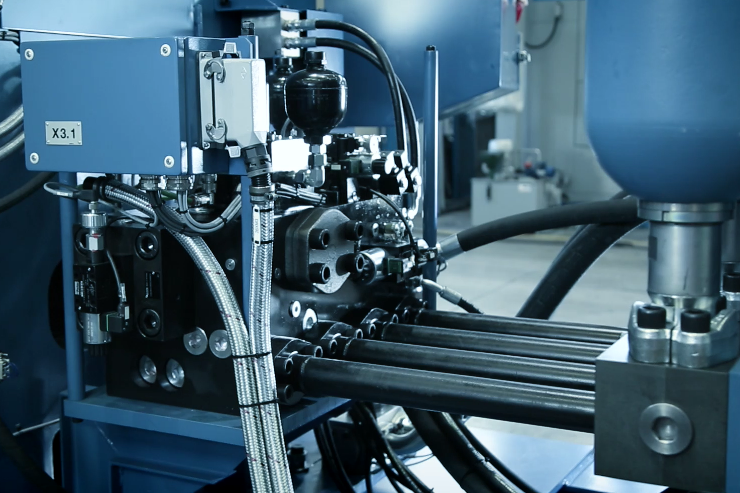

COMMAND GROUP

It includes a compact transmission coaxial to the eccentric shaft including:

– Combined flywheel and reduction unit;

– Combined Hydraulic Brake-Clutch Group, equipped with progressive piston to mitigate shocks and transmission vibrations due to engagement and braking;

– Control valve of the Brake-Clutch group with progressive engagement and braking control;

– Double gear coupling between eccentric shaft and transmission to avoid the transmission of shocks from the crank mechanism to the control unit;

– Main motor with encoder and closed loop control, allows the slow movement of the press for tooling, “Inching mode”.

The flywheel motor system has been completely revised to obtain better resolution and precision in speed control, greater reactivity in the recovery of energy after forging.

A safe speed limit control is foreseen with open front protection, during the set-up phases and a check of a possible excessive slowing down of the machine (for example due to a too large billet).

The motor cooling is constantly ensured regardless of the motor speed, this allows to always guarantee maximum performance.

We have provided an interesting option: the energy that the motor returns to the inverter during the slowdown phases, is put back into the network and not dissipated in heat; in practice it translates into a lower consumption of electricity!

SLIDE

Also the slide has been revised, we have foreseen a motorized adjustment of the vertical light and an extraction bar with hydraulic control.

The sliding skids are oriented radially to the machine axis to reduce the variation of the tolerances with changing temperatures.

The hydraulic system for protection against overload is also inserted in the slide, which is essential for forging on the bottom.

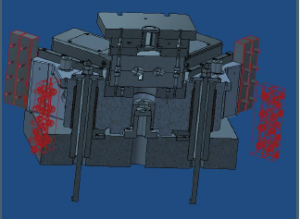

GE EQUIPMENT

– Possibility of mounting the lower punch also with “SOFT IMPACT” cushion,

– Water cooled upper die holder,

– Up to 8 points of lubrication from the lower die holder,

– Up to 4 points of lubrication from the upper die holder,

– Easy equipment change. It is extracted by unlocking the top with pistons that allow extraction on a ball guide.

– Possibility of mounting the motorized adjustment of the punch stroke.

For the HEAVY400 the GE26 is foreseen, which has the following specific features:

– Dies 290 x 290 mm

– 110 mm punch stroke

Thanks to our Extruder Group you can save up to 40% of the material compared to the full forging modes! Check out the details here

“SOFT IMPACT” CUSHION

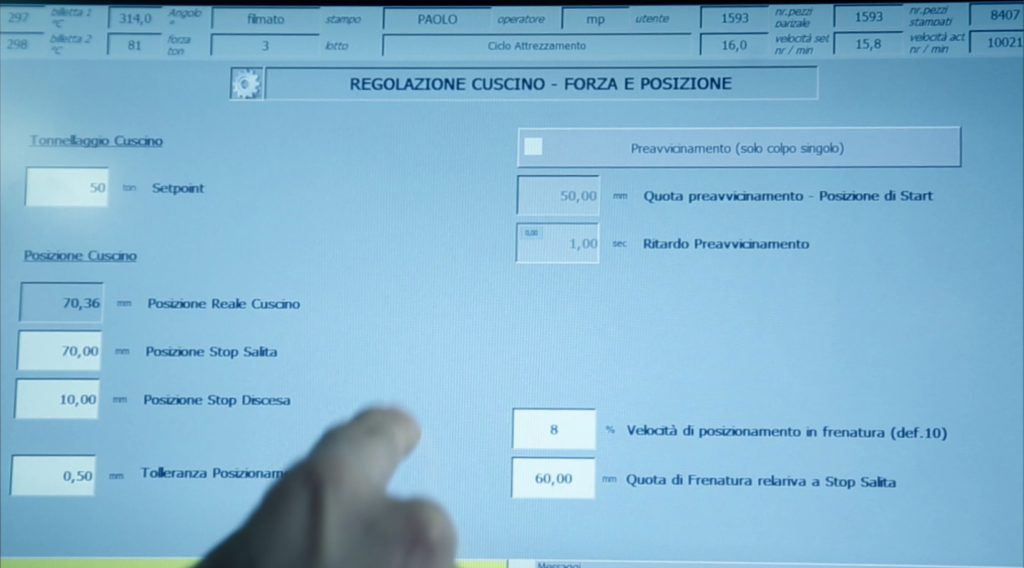

1000 kN hydraulic cushion with complete electronic management, it allows to check the punch height, in addition to limiting the mechanical shock due to the impact between the dies.

The Soft Impact cushion is an important innovation that we have been making for a couple of years, and that is proving to be truly appreciated. Read here to learn more about how it works.

BRCE LOADING DEVICE

The 2-axis rotary loading arm driven by brushless motors has the load angle of the clamp at 45 °, aligned with the dies centre;

The 400 mm vertical stroke allows you to manage any type of equipment without manually changing the position of the arm.

PBSE DISCHARGE DEVICE

The discharge chute has been designed to avoid dents to the forged part; driven by a motor brushless, the unloading arm allows automatic adjustment of the position.

DIE LUBRICATION

We have provided up to 20 lubrication points and 2 dies blowing points, an open and flexible configuration for each type of die and tool.

Also interesting is the possibility of adjusting the amount of oil from the panel, without need of manual adjustments on the machine and on the control unit.

From every point it is possible to blow air to clean / cool the die before every lubrication.

The press is able to warn in advance when it is necessary to fill the hydraulic unit, in order to avoid a machine stop due to lack of fluid.

A digital sensor allows the control of the fluid temperature, the operator can start the production only when the oil is at the correct temperature, an essential requirement for a correct and constant lubrication.

An inverter for pump speed adjustment prevents overpressure peaks and oil dripping when the pump starts with oil still cold; automatically adjusts the oil flow rate according to the quantity needed for use; prevents overheating of the oil in the control unit.

Our lubrication system, unlike the systems marketed up to now, eliminates the problem of the quantity of oil usable for each individual nozzle.

Competitive lubrication systems load a limited amount of oil into a tube and then blow it off with compressed air.

This ensures that 70% of the sprayed lubricant is used only in the first moment of lubrication, while in the remaining cycle the quantity of lubricant decreases until it is completely zeroed.

On the other hand, our lubrication system allows continuous and constant mixing directly at the exit point of the pipe, through our system we can cool and lubricate the dies from the same pipe without affecting the programmed oil quantity.

ELECTRICAL CONFIGURATION

The 24vcc circuits are protected by auxiliary electronic devices, able to provide a quick diagnosis of any short circuits or overloads (also through Teleservice).

This is a very interesting aspect because it allows a greater reliability of the system and a service life up to 10 times greater than normal technology!

The cables are in PUR, protected by steel sheaths and silicone protections against flames, specific for use even in environments deemed aggressive.

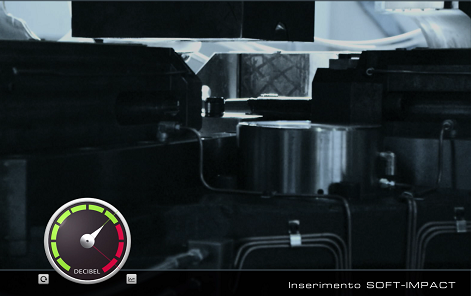

OPERATOR INTERFACE

The Operator Panel is a 15 ″ Siemens Touch Panel to better manage machine data, you can save up to 1000 recipes! And have an alarm history with up to 10,000 events.

Obviously, through the proper configuration of our software, you can receive valuable reports to carry out preventive maintenance.

Another practical example is the notepad function, thanks to which the operator can then write important information and his personal notes, added to each production recipe.

It is possible to obtain a production report, a secure management by 4-level password with autologon function, and much more.

Finally, the movable panel allows close controls on the machine, possibility of movement and programming with front or rear open protection, close to the die (eg die lubrication).

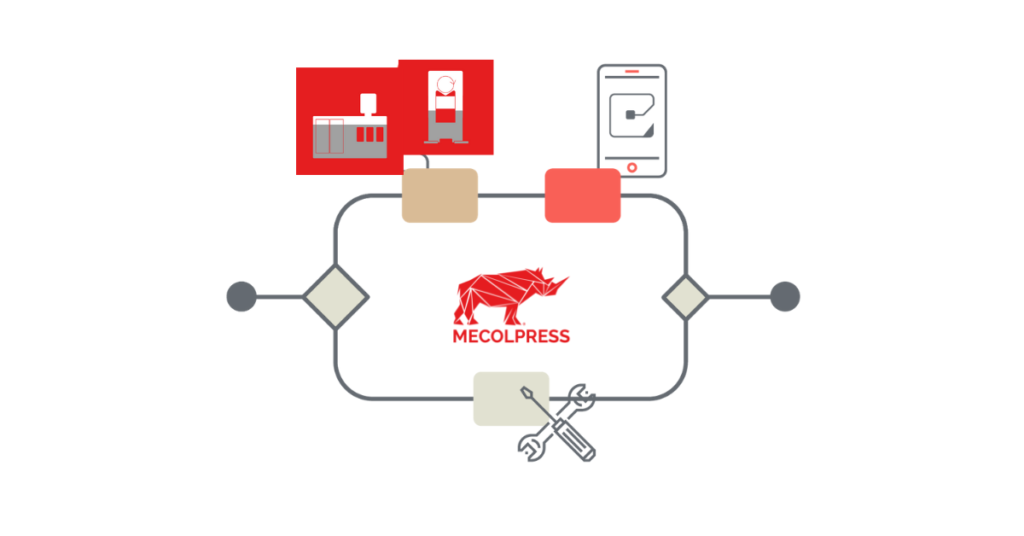

Cloud Presses

This year at EMO2019 we will give practical demonstration of how smart our machines are.

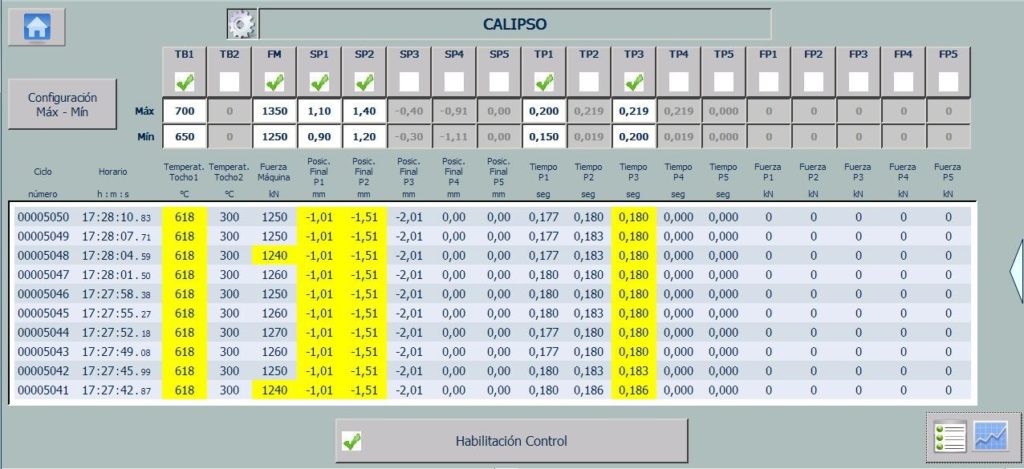

Created by Mecolpress for forging statistic control, Calipso is a software that allows to control the press activities during the entire production cycle, and it is an useful instrument for analyzing the production and for intervening where it is necessary to optimize it.

This intelligent software for the analysis of the production process also includes a sophisticated technology for managing non-conformity

Once all these data have been produced, it will be possible to log them, analyze them and import them into the customer’s management system.

For each machine cycle, a series of parameters are recorded on the operator panel, the last 10 cycles are displayed in tabular form.

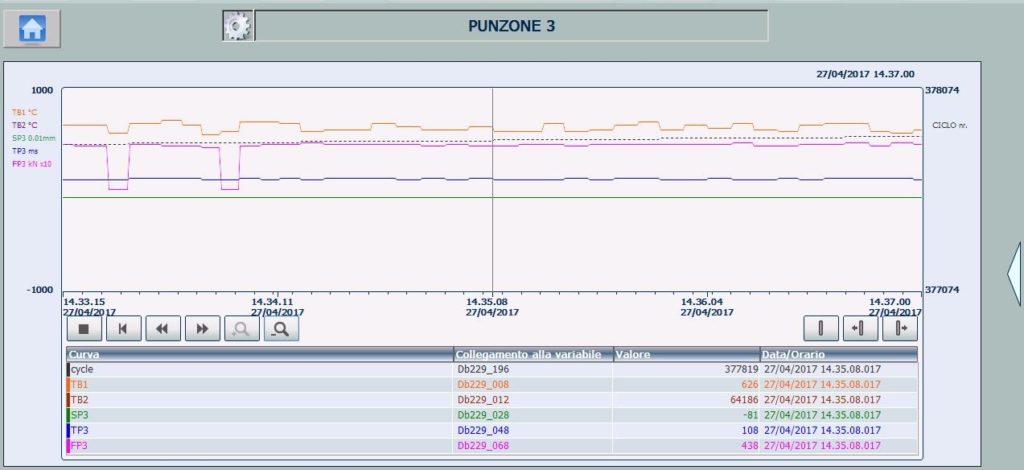

Moreover, the parameters are recorded (the last 10000 cycles) and displayed in the form of trend.

Through the trend it is possible to carry out a cross-check, in order to idedntify the reasons of possible non-conformities.

An example:

At the EMO2019 exhibition in Hanover we present something more:

a practical demonstration, an example of how our machines can communicate with external systems and devices.

Thanks to the collaboration with the Smeup Industrial IoT department, it was possible to integrate our brand new HEAVY 400 mechanical press and ME 100 hydraulics with their IoT Platform.

The production information collected by Calipso can be viewed in real time through dashboards, for an optimal understanding of the data collected by the press.

Dashboards are created using a simple, intuitive and visually striking web tool. Looking at something that is happening at the very moment you are observing is very different from seeing deferred data. In a landscape where speed in making decisions is a determining factor, these tools offer an important contribution.

It is possible to monitor all this, in addition to the local one, also in the cloud: a very interesting aspect as it is possible, through a simple browser, to visualize the result through any instrument connected to the network, from the smartphone to the tablet to the PC, you can always take a look at the data collected, all in real time!

Monitoring the activity of the press, having the information that we are always interested in, getting important alerts or messages useful for example for predictive maintenance, is an interesting plus even for the forging sector that now more than ever becomes intelligent and in step with market demands!

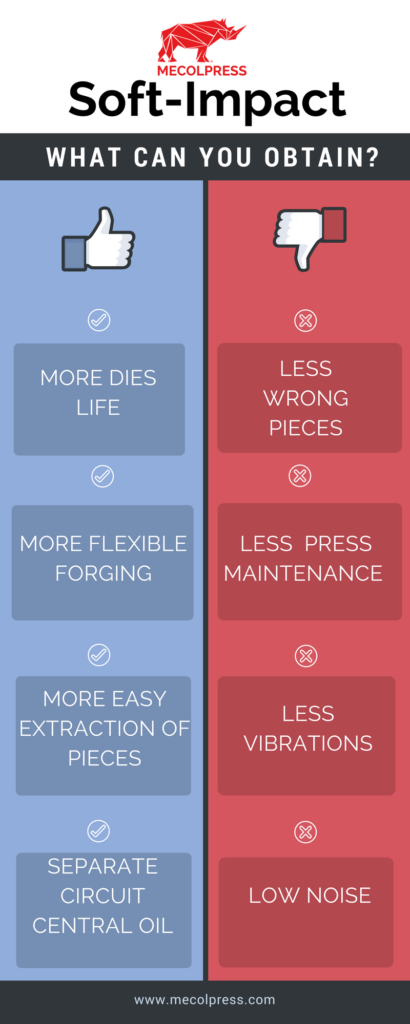

Soft-Impact hydraulic cushion for eccentric mechanical presses

A recent innovation by Mecolpress for eccentric mechanical presses.

Mecolpress proposes to equip the eccentric mechanical presses of an innovative hydraulic cushion, Soft-Impact.

Features:

- It is a real hydraulic cylinder with a stroke sensor on the shaft;

- Movements are fully programmable and controlled by means of proportional valves;

- Starts independently the down-stroke and then the punches move forward toward the die center before the upper die hits the lower one;

- Strokes adjustment from operator panel by simply inserting the desired dimensions and the data of die and die-holder heights;

- As alternative, the function “punches pre-start” allows the punches to move close to the billet before the die closes and the forging begins.

- Dedicated hydraulic unit, separated from the machine clutch one.

Thanks to the here above-mentioned features, the soft-impact hydraulic cushion allows the mechanic eccentric presses to achieve important results:

- Extremely simplified mechanical components;

- Precise adjustment from the operator panel of the start, stop and braking quota; all set parameters are saved together with the piece recipe;

- The upper die does not crash violently against the lower one, because it “reaches” the second one while it is already in the descending phase;

- The control system automatically calculates the speed and the moment to start the cushion;

- When the material deformation begins, the punches are already in an advanced position decided by the operator (it can be saved in the piece recipe); when the die re-opens, the punches then go back beyond the quota of work start;

- Separate blocks modular system.

Benefits:

- Less and simpler maintenance;

- Ease of use, machine set-up and perfect repeatability of forging’s cycles;

- Reduction of vibrations, resulting in general benefits for the press and for the working environment;

- Reduction of noise;

- Increased working life of dies and pins;

- No complicated calculations or measures for the operator;

- Possibility of reduction of forging defects due to material that goes out along the empty punch channels and then is pushed inside by punches starting their stroke too distant;

- Ease ejection of pieces (having an extra back stroke) without penalizing the cycle time;

- The oil in the cushion control unit has its own independent circuit and does not mix with the clutch oil, usually dirtier.

The presence of Mecolpress at Korea Metal Week 2017

We are exhibiting at the Korea Metal Week show at the Kintex Exhibition Center in Seoul,

from 24th to 27th of October

As Korea’s leading international trade exibithion, Korea Metal Week offers the best market with the latest technology for suppliers, manufacturers and operators of the metal industry worldwide.

Korea Metal Week 2017 includes eight well organized fairs that integrate all metal production technologies.

Korea Metal Week, already established as the largest trade fair in the metalworking and machining sector in Korea, will be an important trading and sharing opportunity with hot forging industry from around the world.

Mecolpress will have its own booth at the show, and you can meet there the sales manager from the Italian headquarters and the Korea sales representative.

They will be glad to present to you the whole Mecolpress range of presses for hot forging of metals, with examples of real applications solutions.

It will be a great opportunity for you to learn the advantages that a Mecolpress Forging Line can offer to your company.

We look forward to see you there!

Mecolpress will attend

Korea Metal Week (Kintex Seoul – Korea)

from October the 24th to 27th.

We are at Booth 8A120