The dies lubrication determines your forging success!

Knowing to take advantage of the correct dies lubrication is crucial in a hot forging system of brass, steel, aluminum, titanium or copper parts.

We have already highlighted many times in our previous articles how the lubrication can make the difference and solve many of the common problems that the forgers observe during the production of their forged parts. Our research of the perfect lubrication has evolved, becoming more and more precise and customizable, exactly like we are constantly required by the market.

A correct lubrication doesn’t mean that it must be of large quantity, but that it must be correctly dosed and the most appropriate lubricants must be chosen according to the metal types and required part to be forged.

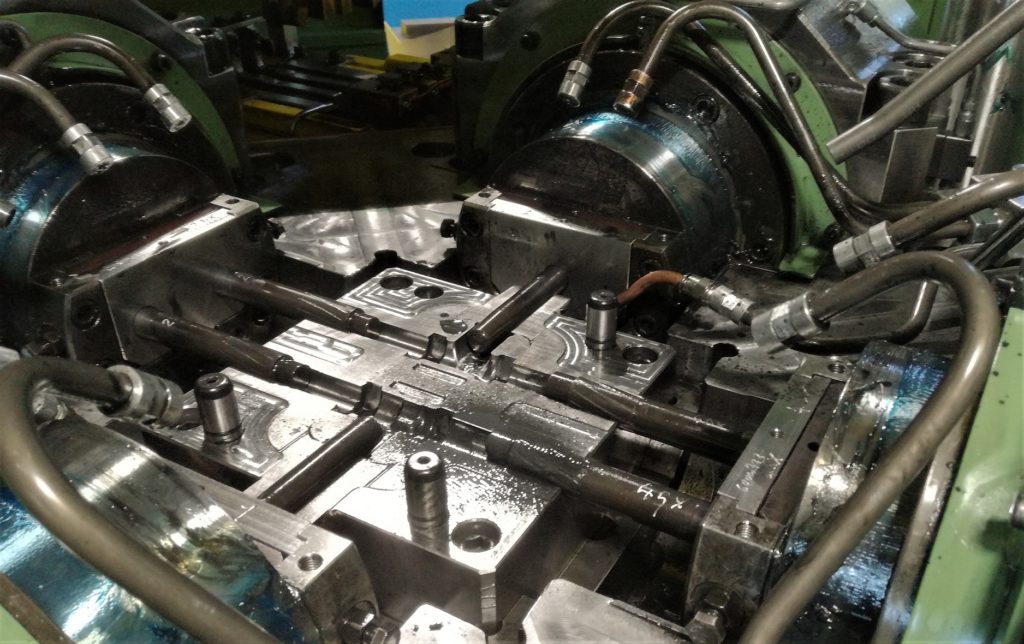

The dies lubrication system of hydraulic presses of ME series and of eccentric press at continuous cycle of HEAVY series

With the hydraulic presses of ME series and the mechanical eccentric at continuous cycle presses of HEAVY series we have revolutionized the dies lubrication system:

- We drag the outgoing oil+graphite mixture on the lubrication point.

- We let the lubrication liquid and the compressed air flow in two concentric tubes of the control valves of the single points up to the usage point.

- For each of the points the pilot is independent and therefore for each of them we give the possibility to the user to choose from the operator panel how, when and how often to intervene.

But we were not satisfied yet!

Which are the requests the forgers most frequently address to us?

We have verified that some of the questions you ask our service department are regarding the lubrication system:

“My die has broken, what can I do to guarantee it a long-lasting life?”

“The dies lubrication system I am using is not satisfying.”

“Is it possible to reduce the waste of lubricants, in view of an even more ecological choice?”

“How can I obtain a successful forging system?”

Our Research and Development team has therefore perfected and developed a new lubrication system.

What’s new in the lubrication system of the HEAVY series

Heavy series is our new proposal of a mechanical eccentric at continuous cycle press. It is a very revolutionary machine, the result of 50 years of experience in the hot forging presses production, and of the continuous search for innovation and technology perfection.

As a result, we have completely reviewed even the automation and the dies lubrication.

First of all, the dies lubrication system allows for each single point the independent and programmable management.

It is possible to start the lubrication cycle in different ways: during the ascent or descent of the ram, during the loading or unloading cycle, with appropriate delay and duration times.

Each point can be used for the nebulization of the lubricant or for the cooling and cleaning of the dies.

The system can be implemented with 2 or more high capacity air blowing points.

It is possible to program the schedules: the pumping circuit, the automatic mixer and the heating resistance placed in the tank allow to prepare the liquid and the entire circuit for the starting time at optimal conditions.

The nebulization of the lubricant, thanks to the particular pipe system, is obtained only in proximity of the usage area: in this way the dosage, repeatability and the sensibility to the dosage variation are guaranteed.

40 lubrication/cooling points are foreseen, of which 16 are placed in the lower dies-holder and 16 in the upper dies-holder. The disposition of the lubrication/cooling points throughout the dies allows to reach efficaciously the critical points to be lubricated/cooled, in addition to drastically reduce the times of production change.

Reactive, smart system for creating your recipes

The responsiveness to the settings variations is immediate, unlike the traditional system that requires several minutes of production before it stabilizes.

In addition to this, we can have a strong blowing without the help of compressors (that are contributing to increase the consumptions and the general maintenances of the plant).

A smart software system helps moreover the operator to adapt automatically the dosage of the lubricant in the startup phase of the production, till to reach the correct forging conditions.

Our system can be adapted even to the use of lubricant/water-base release agent, e.g. used in the aluminum sector, that are different from the classic graphitized oil.

All the parameters, activation of the used points, start modalities, timers and counters, once they have been optimized, are saved in the recipe devoted to the type of the part to be produced, in order that for the following batches of the same article there is a fast production start without useless waste of time.