MIA: Mecolpress Artificial Intelligence

AUTOMATING THE OPERATION ASSISTANCE WITH ARTIFICIAL INTELLIGENT

We are pleased to communicate an important innovation in the hot forging sector: we have managed to successfully implement a solution based on Artificial Intelligence which adds considerable value to our assistance service!

Why have we decided to integrate the Artificial Intelligence in our Assistance service?

The implementation of a technology based on the artificial intelligence can significantly improve our assistance service:

- Reduction of technical support times

- Assistance automating for presses troubleshooting

- To provide access to manuals and guides 24 hours a day, 7 days a week

- To grant a prompt problem managing on the production lines.

- To directly obtain a multilingual support to meet the needs of customers all over the world.

- Autonomous and prompt problems managing directly on customer production lines.

- To have an immediate response to press alarms and signals.

What exactly does MIA – Mecolpress Artificial Intelligence consist of?

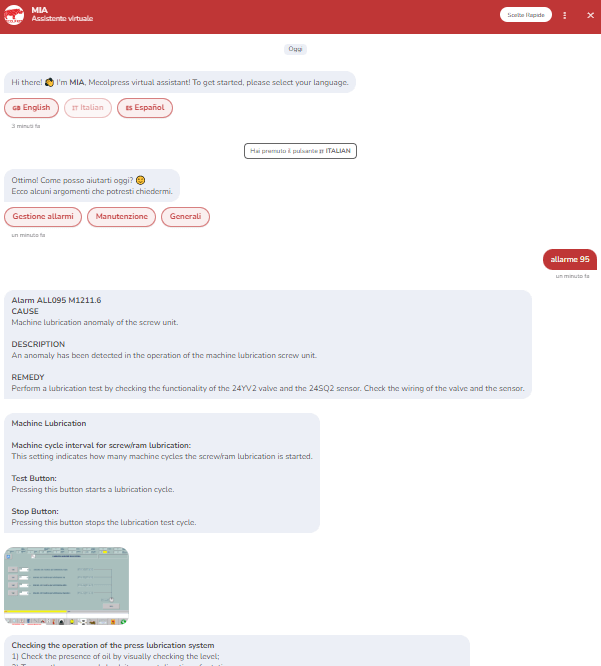

MIA is a technology based on generative AI and Retrieval-Augmented Generation (RAG) to offer Mecolpress an advanced virtual assistant that supports technicians in the maintenance and troubleshooting of presses, 24 hours a day, 7 days a week.

The 3 MIA great adavantages

- Maintenance automation and Troubleshooting

The system developed by Userbot.AI has been trained on the manuals of Mecolpress machines and on the history of over 450 types of alarms, allowing operators not only to obtain immediate answers to technical questions directly from the production lines, but also to have instant support and with step-by-step guides for resolving critical alarms. Operators can consult information via tablet or smartphone, significantly reducing the time needed to resolve technical problems.

- Multilingual support

To facilitate access to information by international customers and operators, the virtual assistant has been implemented with multilingual functionality in Italian, English and Spanish, but also allowing translation into 100 other languages in real time thanks to Generative AI, thus ensuring fluid and understandable communication for all users.

- Customer Experience Improvement

The virtual assistant improves the customer experience, reducing waiting times and providing immediate and accurate responses 24 hours a day. This translates into reduced operational disruptions and a higher level of customer satisfaction. Furthermore, thanks to this new system, the digitalisation of information is achieved concretely, not just in words. Thanks to this project, the user has immediate access to all the information contained in the use and maintenance manual, which given the complexity of the machines, is over 1,000 pages.

Which are MIA goals?

Thanks to virtual assistance based on AI, we set ourselves the goal of obtaining significant results in terms of operational efficiency.

It is estimated that, once fully operational, the system can lead to:

- a 60% reduction in support/assistance times, allowing operators to obtain immediate answers to the most common questions without having to wait for technical support to intervene.

- to reduce the number of human support tickets by up to 40%. This result will be possible thanks to the automation of troubleshooting and quick consultation of manuals directly via the virtual assistant. In this way, requests that currently overload technical support can be managed independently by operators in real time.

- to create a smoother and more responsive customer experience, with a significant improvement in the quality of service offered by Mecolpress.

MIA future evolutions

In the future, Mecolpress plans to expand the use of the virtual assistant to other product lines, also extending support to new markets.

Furthermore, Mecolpress is considering using the bot to support its partners and resellers around the world, offering them easier access to technical information and product training.

Below is the article published on the Smeup website regarding our experience of implementing Artificial Intelligence in our assistance service:

Mecolpress: automating the operation assistance with AI

Here below you can find two quotes contained in the above-mentioned article:

“I am enthusiastic about the journey we are taking with Userbot.AI. I have always believed in innovation, and, thanks to this solution, we are able to provide immediate and continuous support to our operators around the world. I have involved a highly qualified team to work on the integration of our machine manuals and, so far, the results have gone far beyond initial expectations. I am sure that this technology will allow us to significantly improve our operational efficiency and technical support to customers. “

— Carlo Contri, Mecolpress Technical Manager

“The partnership with Mecolpress demonstrates how generative AI and advanced Retrieval-Augmented Generation (RAG) technologies can revolutionize technical assistance in the industrial sector. This project represents a concrete example of how artificial intelligence and large language models can enhance operational efficiency and radically transform the way companies approach maintenance and technical support even in highly innovative and technically complex environments such as that of Mecolpress.”

– Antonio Giarrusso, Userbot Executive President

Remote forging test

Case study: remote forging test for the acceptance of an entire line

A few weeks ago we carried out a forging test completely on-line.

Generally, it’s the customer who comes to Mecolpress site and follows all the agreed forging tests, the complete development of the necessary activities and the forging phases of the agreed parts.

For the customer this means in any case to travel, physically being absent for some days from the office and personal business, incurring more or less important costs … in conclusion facing challenges weighed down by the situation that has developed because of Covid-19.

In order to meet the need of our customer we have ensured that the forging test for the acceptance of the entire line, that has as cornerstone our ME350 hydraulic press, was carried out totally on-line.

Therefore, we proceeded this way:

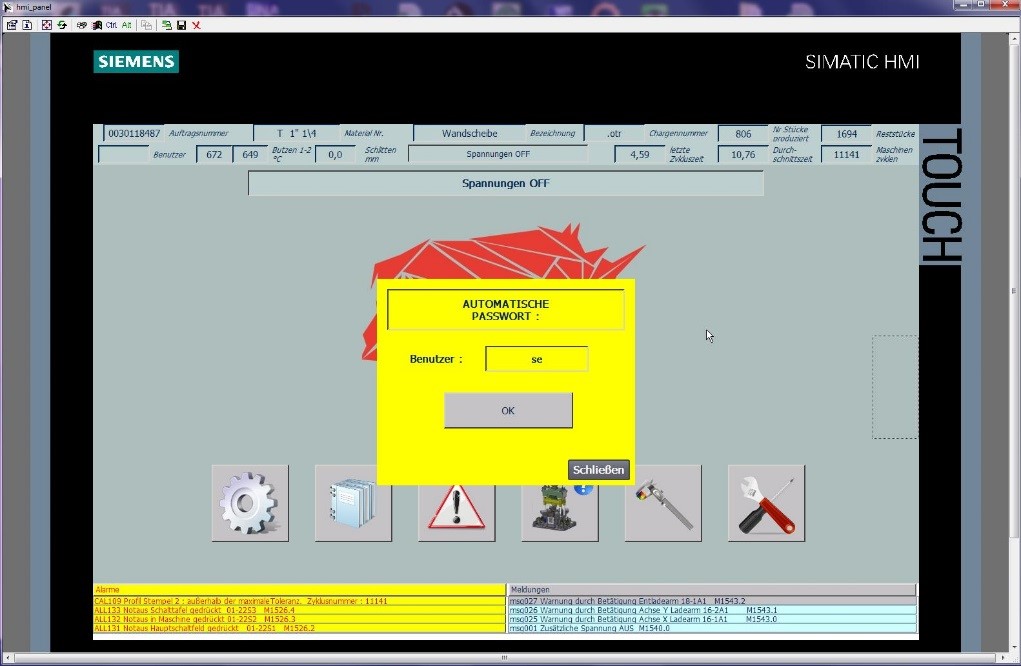

- The customer installs a software indicated by Mecolpress for a safe and certificated VPN connection.

- In this way a connection between customer internet and the press located in Mecolpress is established.

- Now the customer can access directly the machine operator panel.

4. We installed 2 video cameras, reachable by means of ip-adress, running for the whole production duration. The customer can follow the video live from any PCs.

5. Always only inside the established VPN it is possible to access through browser to the two cameras that are always on during the entire forging phase.

6. A technical support representative in Mecolpress is always and in any case available by telephone.

7. All the procedures regarding the setup phase and in particular the die changing phase are visible.

8. All the videos and pictures are therefore strictly confidential and visible from a webcam only to the customer that can save videos, if he considers it appropriate, or taking some pictures, everything always with the maximum confidentiality.

Which have been the advantages for our customer?

The advantages resulting from this acceptance-from-remote procedure of an entire hot forging line are easily identifiable:

- Time-saving,

- Costs-saving,

- Possibility that more people can follow the forging test, comfortably in front of a PC.

New procedures for remote tests

These methods of digital implementations are fundamental, but we still believe that in the world of precision mechanics and capital goods, the aspect of customer consultation is crucial and that as a result the personal contact is still necessary to carry out efficient projects according to partnership optics with the customer and to a deep understanding of his necessities.

Anyway, it is important to offer to our customers the alternative of remote forging tests. The customer experience is however total: video connections, real time data extraction, possibility to access to the press panel.

This procedure can bring also to future developments, for example, let’s think about how it can be useful if it would be set up on the contrary: a Mecolpress technician could have all the useful tools for diagnosing a problem on a machine located in Australia and solve it immediately! Without taking the plane, without taking a long journey, without charging important costs to the customers, avoiding long machine stops.

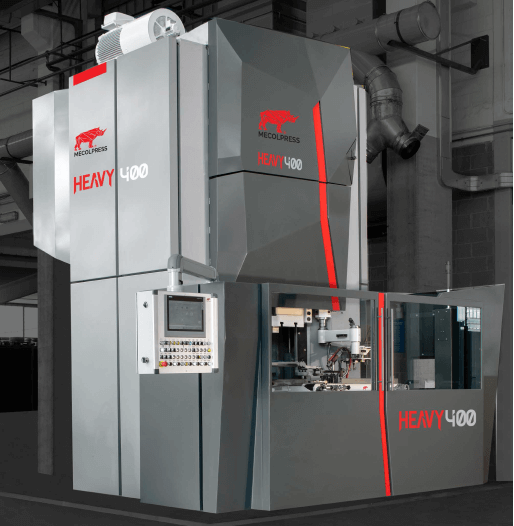

HEAVY SERIES MECHANICAL PRESSES

Mecolpress, at the EMO exhibition in Hannover which took place last September, officially presented the new series of eccentric continuous cycle mechanical presses, the HEAVY series.

Based on the experience accumulated over 50 years of designing and manufacturing presses for hot forging metal, we have succeeded in creating a totally renewed mechanical press.

We are sure that our new project will mark the beginning of a new era for hot forging!

What are the main strengths of the new HEAVY mechanical presses?

-

- A structure that is certainly innovative and modern, more robust and designed to simplify control and maintenance;

- Fully revised die automation and lubrication;

- Our innovative hydraulic cushion, the Soft-Impact, which allows to achieve important results including for example the possibility of vibrations reducing;

- The updated version of our intelligent Calipso software, for the analysis of the production process and for predictive maintenance.

Let's analyse the features in detail:

STRUCTURE

The structure of the machine is made in such a way as to separate the dangerous area (moving parts and die area) from the areas accessible to the operator for adjustments and ordinary maintenance, through front protections and soundproofing material casings, as required by CE standards.

Directly on the vertical part of the forging area, the fume extraction is obtained through metal ducts with connection to the customer’s centralized system.

The control unit for centralized lubrication of the press, the regulators of the pneumatic system and of the die lubrication system and the electrical equipment are inserted in large protected cabinets and easily accessible to the operator, not reached by the fumes and the oil of die lubrication .

The assembly of the main parts to the machine is designed to simplify inspection and maintenance.

COMMAND GROUP

It includes a compact transmission coaxial to the eccentric shaft including:

– Combined flywheel and reduction unit;

– Combined Hydraulic Brake-Clutch Group, equipped with progressive piston to mitigate shocks and transmission vibrations due to engagement and braking;

– Control valve of the Brake-Clutch group with progressive engagement and braking control;

– Double gear coupling between eccentric shaft and transmission to avoid the transmission of shocks from the crank mechanism to the control unit;

– Main motor with encoder and closed loop control, allows the slow movement of the press for tooling, “Inching mode”.

The flywheel motor system has been completely revised to obtain better resolution and precision in speed control, greater reactivity in the recovery of energy after forging.

A safe speed limit control is foreseen with open front protection, during the set-up phases and a check of a possible excessive slowing down of the machine (for example due to a too large billet).

The motor cooling is constantly ensured regardless of the motor speed, this allows to always guarantee maximum performance.

We have provided an interesting option: the energy that the motor returns to the inverter during the slowdown phases, is put back into the network and not dissipated in heat; in practice it translates into a lower consumption of electricity!

SLIDE

Also the slide has been revised, we have foreseen a motorized adjustment of the vertical light and an extraction bar with hydraulic control.

The sliding skids are oriented radially to the machine axis to reduce the variation of the tolerances with changing temperatures.

The hydraulic system for protection against overload is also inserted in the slide, which is essential for forging on the bottom.

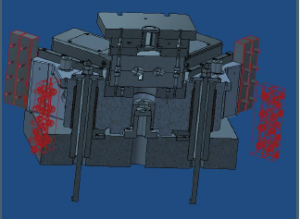

GE EQUIPMENT

– Possibility of mounting the lower punch also with “SOFT IMPACT” cushion,

– Water cooled upper die holder,

– Up to 8 points of lubrication from the lower die holder,

– Up to 4 points of lubrication from the upper die holder,

– Easy equipment change. It is extracted by unlocking the top with pistons that allow extraction on a ball guide.

– Possibility of mounting the motorized adjustment of the punch stroke.

For the HEAVY400 the GE26 is foreseen, which has the following specific features:

– Dies 290 x 290 mm

– 110 mm punch stroke

Thanks to our Extruder Group you can save up to 40% of the material compared to the full forging modes! Check out the details here

“SOFT IMPACT” CUSHION

1000 kN hydraulic cushion with complete electronic management, it allows to check the punch height, in addition to limiting the mechanical shock due to the impact between the dies.

The Soft Impact cushion is an important innovation that we have been making for a couple of years, and that is proving to be truly appreciated. Read here to learn more about how it works.

BRCE LOADING DEVICE

The 2-axis rotary loading arm driven by brushless motors has the load angle of the clamp at 45 °, aligned with the dies centre;

The 400 mm vertical stroke allows you to manage any type of equipment without manually changing the position of the arm.

PBSE DISCHARGE DEVICE

The discharge chute has been designed to avoid dents to the forged part; driven by a motor brushless, the unloading arm allows automatic adjustment of the position.

DIE LUBRICATION

We have provided up to 20 lubrication points and 2 dies blowing points, an open and flexible configuration for each type of die and tool.

Also interesting is the possibility of adjusting the amount of oil from the panel, without need of manual adjustments on the machine and on the control unit.

From every point it is possible to blow air to clean / cool the die before every lubrication.

The press is able to warn in advance when it is necessary to fill the hydraulic unit, in order to avoid a machine stop due to lack of fluid.

A digital sensor allows the control of the fluid temperature, the operator can start the production only when the oil is at the correct temperature, an essential requirement for a correct and constant lubrication.

An inverter for pump speed adjustment prevents overpressure peaks and oil dripping when the pump starts with oil still cold; automatically adjusts the oil flow rate according to the quantity needed for use; prevents overheating of the oil in the control unit.

Our lubrication system, unlike the systems marketed up to now, eliminates the problem of the quantity of oil usable for each individual nozzle.

Competitive lubrication systems load a limited amount of oil into a tube and then blow it off with compressed air.

This ensures that 70% of the sprayed lubricant is used only in the first moment of lubrication, while in the remaining cycle the quantity of lubricant decreases until it is completely zeroed.

On the other hand, our lubrication system allows continuous and constant mixing directly at the exit point of the pipe, through our system we can cool and lubricate the dies from the same pipe without affecting the programmed oil quantity.

ELECTRICAL CONFIGURATION

The 24vcc circuits are protected by auxiliary electronic devices, able to provide a quick diagnosis of any short circuits or overloads (also through Teleservice).

This is a very interesting aspect because it allows a greater reliability of the system and a service life up to 10 times greater than normal technology!

The cables are in PUR, protected by steel sheaths and silicone protections against flames, specific for use even in environments deemed aggressive.

OPERATOR INTERFACE

The Operator Panel is a 15 ″ Siemens Touch Panel to better manage machine data, you can save up to 1000 recipes! And have an alarm history with up to 10,000 events.

Obviously, through the proper configuration of our software, you can receive valuable reports to carry out preventive maintenance.

Another practical example is the notepad function, thanks to which the operator can then write important information and his personal notes, added to each production recipe.

It is possible to obtain a production report, a secure management by 4-level password with autologon function, and much more.

Finally, the movable panel allows close controls on the machine, possibility of movement and programming with front or rear open protection, close to the die (eg die lubrication).