Interviews in the company: Riccardo Segreto

At Mecolpress offices we met Mr. Riccardo Segreto, person in charge of dies test and brass forging department.

What is your role in the company?

I follow the dies design for the parts forging both in brass and aluminum. Then I follow the starting test for the set-up of the die with all the necessary procedures to prepare it, to make it work properly, also suggesting the proper maintenance.

From which sector do you come from?

I have 25 years of experience in the forging sector, during which I mainly took care of brass hot forging process.

So, we are mostly speaking about brass. There are different types…

Indeed, the brass is an alloy that can be combined in many different types. Recently the tendency to produce it without lead is affirming. In this Italy follows Germany, where Ecobrass is used for a few years now, that indeed is without lead. Since the brass produced parts are largely directed to the domestic water circuits and installation, it is clear that the presence of lead represents a danger.

In the sector of taps and fittings, components, the same norms forbid the lead usage.

This is good for our health but taking off the lead from the brass alloy means to reduce its processability and this reflects on the machines, because the traditional ones are no more adequate, for example due to high cycle times or uncontrollable vibrations during the working phase.

Critical issues that arrive then to the machines. What is the answer from Mecolpress?

The company philosophy is focused on the absolute quality. Translated into concrete terms, regarding brass it means to be able to forge without flash. In this case, our hydraulic presses are very efficient. These are machines that guarantee a drastic reduction of wastes and an optimum quality of parts.

Do you speak about all parts, without differences?

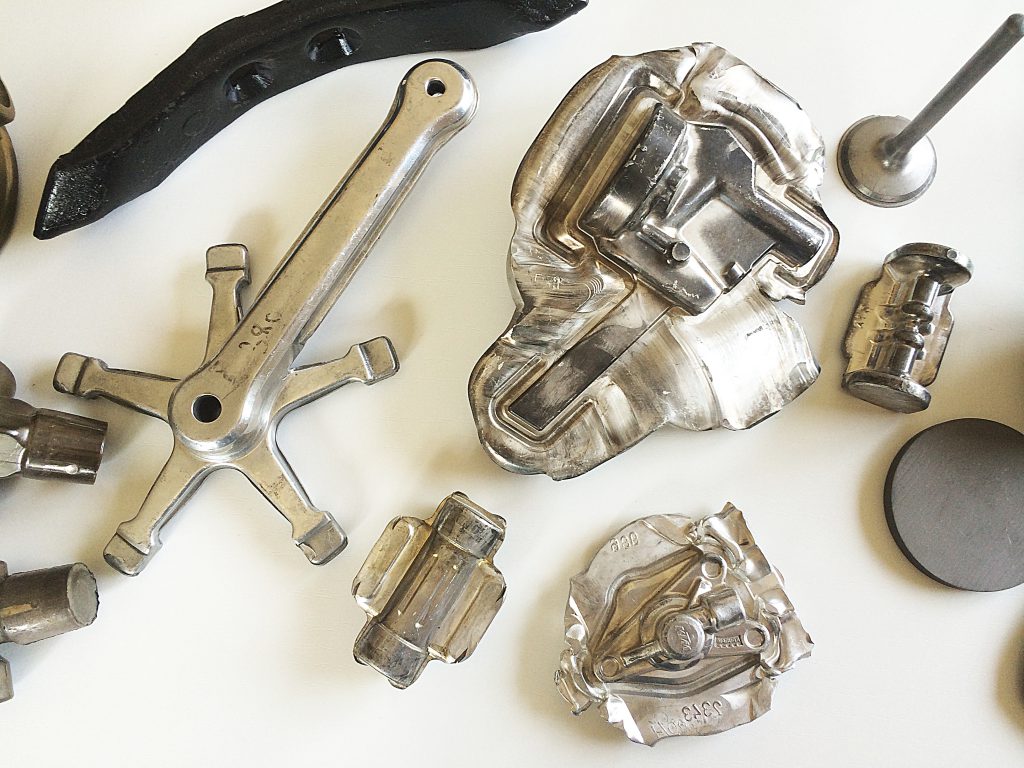

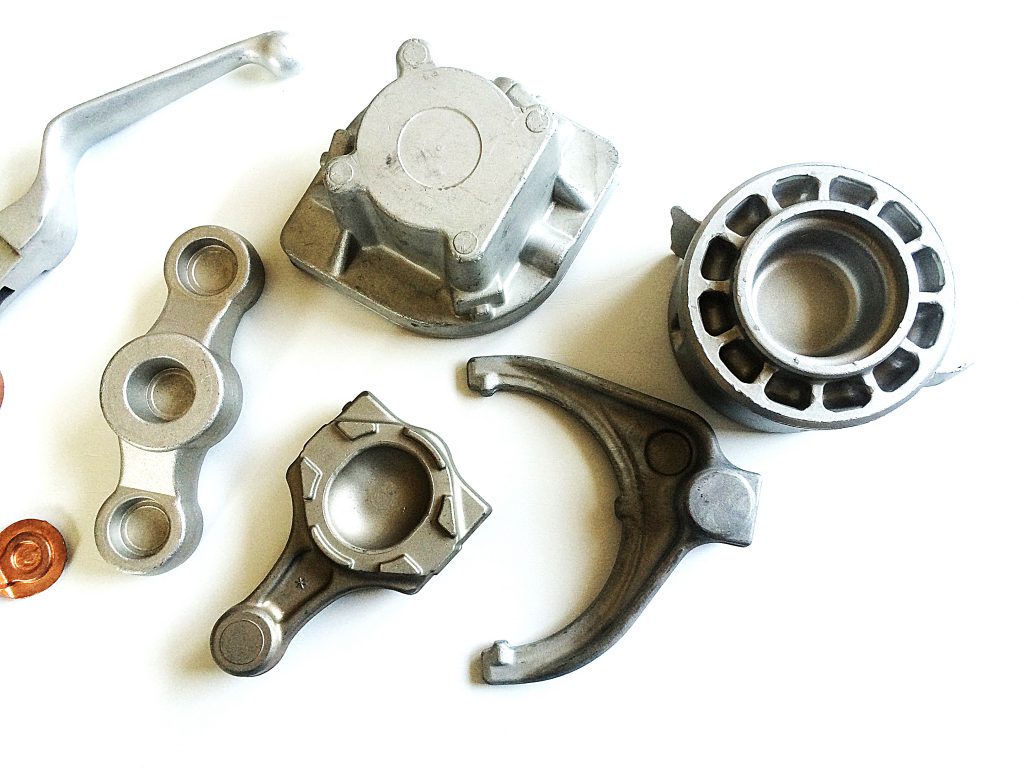

Yes, the range of productions is very wide, from the ball valves to the T junctions, from components for gas plants to automotive parts. The choice is complete.

Which features contribute to the good functioning of the machine?

Reaffirming that when there is no flash some problems can be considered as to be solved, I would mention the simulation program that is a valid help for the forging of very particular parts. It is a software that, once the parametrization is given by the Mecolpress designers, shows the material flow inside the die, allowing to prevent deformation flaws in the points of impact or the brusque alterations of temperature that generate criticalities in the parts. Even if it does not replace the sensitivity of an artisan, and his experience can indicate reliably the points that need adjustments and corrections. And it allows – this is the advantage – to intervene in time.

The message of Mecolpress is above all a call to quality. How do the customers react?

Many operators of our sector are at this point convinced that our advantage incentive is the quality. They understand that to stay active on the international market, they need to be protected, and not to give up with the features for which the Italian companies are always very appreciated worldwide. It is not convenient to lose time in the battles on new orders fighting on few euros, according to us it is always better to offer a 100% quality standard. This is the distinctive characteristic of our presses and the factor that brings more satisfactions.

I mention gladly the last one: we are working hard on a test of 100.000 parts (brass sanitary taps and fittings), commissioned by a German producer that turned to us after he asked to competitors. They request to forge 100.000 parts without flash and without changing the die: we took up the challenge, but we are sure that we will win the challenge.

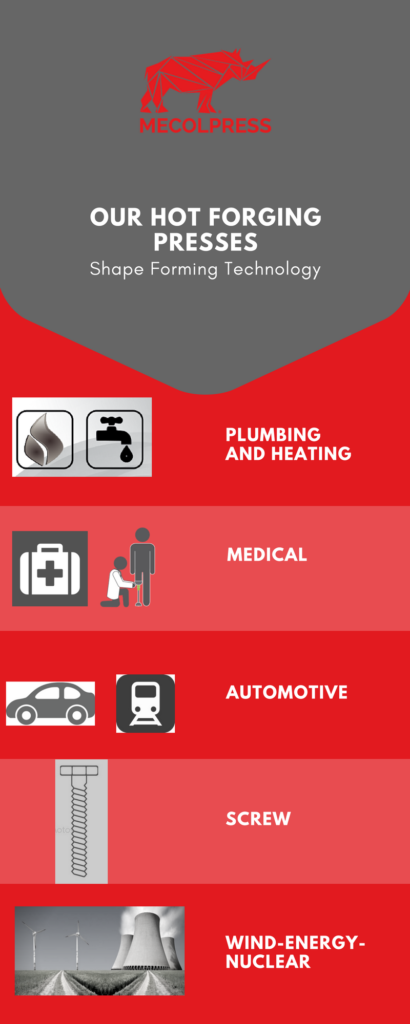

Hot forging presses: Mecolpress technology

Application sectors of the hot forging

Mecolpress offers a wide range of hot forging presses, able to satisfy the necessities of the individual customers and that allow to forge parts for different industrial sectors. Our presses can be used for the production of:

- Thermohydraulic pieces;

- Mechanical parts in aluminum, copper and brass, used in the railway and automotive sector;

- Clothing parts such as buckles and zippers;

- Stainless, titanium and steel screws for applications in any sectors, from the aeronautics to the railway.

The bio-medical one represents a very particular sector, indeed, with our presses it is possible to forge parts for titanium prothesis. The pieces produced by Mecolpress machines address also to the sector of the production and distribution of high-pressure gas, for the medical, automotive and industrial sector.

Not only mechanical presses, here the Mecolpress proposals

A functional commitment that all these sectors have in common undoubtedly is the precision during the material forging, but also from a design point of view Mecolpress reaches through the research for the perfect shapes a remarkable significance. This is exactly why we propose different typologies of presses, including hydraulic presses, mechanical presses, clutch and electrical servomotor screw press, knuckle joint press and trimming machine, that are able to hot forge several materials, including brass, steel, aluminum, titanium and copper.

The support of our Research & Development department

Our range of presses, so differentiated, is due to the work of our Research and Development department, a team that has revealed itself as very precious, not only for Mecolpress Company but also for our customers, because it allows them to achieve several goals. First of all, our staff helps the forger to identify the systems to optimize the production through hot forging of parts in such a way that the further machining will not be needed. Moreover, our specialists can evaluate what could be the productive implications in the usage of different metals alloys and help to identify them. The Research & Development department offers support also for adapting the complete hot forging line composition according to the customer’s needs, to his industrial sector and to the habits of the specific Country.

So, our company is at disposal of the customers in such a way to define with them the hot forging processes, in order to achieve the best result in the production also of high tech parts.

Materials Forged

Mecolpress is leader in the production of industrial presses for the hot forging of materials like:

brass, titanium, aluminium, copper and steel.

The competence of the Research and Development department of Mecolpress support our customers to obtain several goals:

- To be informed about the methodologies to optimize the production thanks to the hot forging of the parts in an efficient way, without the need of subsequent operations like trimming the flash or similar, and also in an effective way, producing a piece that is robust and perfect as the shape to which is inspired;

- To learn which are the most suitable materials for which applications and determine in which conditions the properties of the materials itself are best performing;

- To adapt the best production technics to the need of specific industry sectors, to particular countries prescriptions, according to the local laws and styles.

Mecolpress is therefore a competence centre for the hot forging of material on international level, and this also thanks to the global success that the company has reached in its history.