Friction Srew Press – MECSPE 2020

Mecolpress will partecipate in MECSPE, at Fiere di Parma from 29 to 31 October 2020.

We exhibit the FPN 220 friction screw press.

For 19 editions MECSPE has been the greatest event focused on innovations for the manufacturing industry.

The numbers of Mecspe:

135.000 SQUARE METERS

56.498 VISITORS

2.306 EXHIBITORS

12 THEMATIC SHOWS:

360° innovation, the fair offers a complete overview of innovative materials, machines and technologies, Industry 4.0.

This event offers an interesting moment of meeting between companies, professionals and associations to build new opportunities for the manufacturing market.

Get your free admission ticket

To facilitate the visit and access safely, it is advisable to register to get the free admission ticket.

You can request it by simply filling out this form:

This ticket will allow you to access the exhibition area, participate in conferences, attend the demonstration areas and special initiatives of Mecspe 2020, and take advantage of free parking.

You can find us here:

MECOLPRESS

Hall 8 Non-ferrous materials and alloys, Stand M24.

For the 2020 edition of MECSPE, Mecolpress exhibits the FPN 220 Friction Screw Press

The screw presses like the one we bring to MECSPE are used for the hot forging of brass and steel parts, or with any type of material in general.

They are characterized by the production of solid pieces, or that require multiple forming steps.

Find out more by consulting the screw presses category on our blog.

We are therefore waiting for you at MECSPE!

MECSPE

Location: Fiere di Parma

Address: Viale delle Esposizioni, 393A – 43126 PARMA (PR)

Date: 29 – 31 October 2020 – Thursday, Friday, Saturday

Opening Hours: 9.00 – 18.00 (Thursday and Friday); 9.00 – 17.30 (Saturday)

Visitor entrances: Reception Sud, Est, Nord, Ovest

Visitor Parking: adjacent to the entrances

https://www.mecspe.com/en/magazine/

The excellence of technology applied to industry.

Cloud Presses

This year at EMO2019 we will give practical demonstration of how smart our machines are.

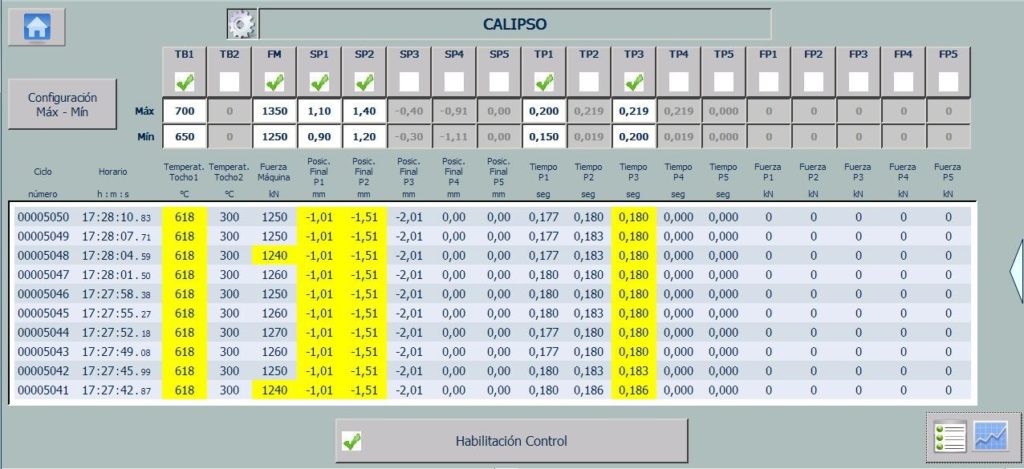

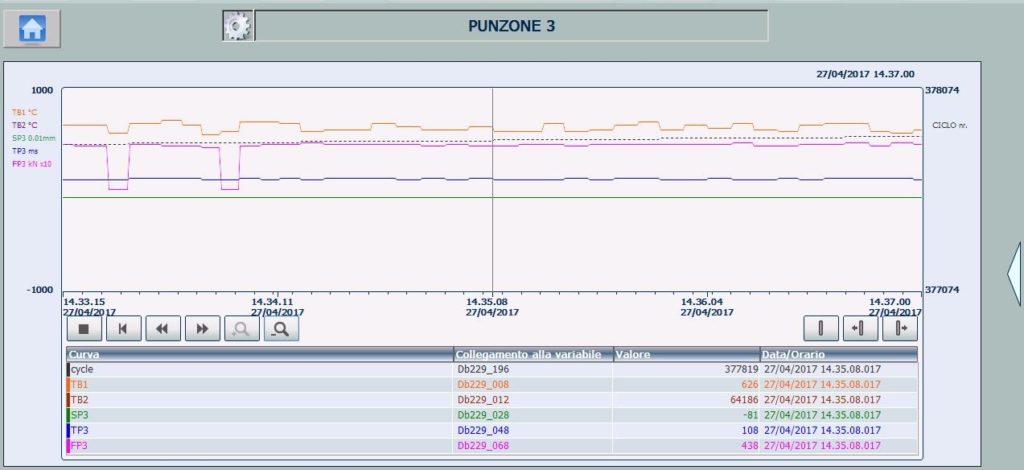

Created by Mecolpress for forging statistic control, Calipso is a software that allows to control the press activities during the entire production cycle, and it is an useful instrument for analyzing the production and for intervening where it is necessary to optimize it.

This intelligent software for the analysis of the production process also includes a sophisticated technology for managing non-conformity

Once all these data have been produced, it will be possible to log them, analyze them and import them into the customer’s management system.

For each machine cycle, a series of parameters are recorded on the operator panel, the last 10 cycles are displayed in tabular form.

Moreover, the parameters are recorded (the last 10000 cycles) and displayed in the form of trend.

Through the trend it is possible to carry out a cross-check, in order to idedntify the reasons of possible non-conformities.

An example:

At the EMO2019 exhibition in Hanover we present something more:

a practical demonstration, an example of how our machines can communicate with external systems and devices.

Thanks to the collaboration with the Smeup Industrial IoT department, it was possible to integrate our brand new HEAVY 400 mechanical press and ME 100 hydraulics with their IoT Platform.

The production information collected by Calipso can be viewed in real time through dashboards, for an optimal understanding of the data collected by the press.

Dashboards are created using a simple, intuitive and visually striking web tool. Looking at something that is happening at the very moment you are observing is very different from seeing deferred data. In a landscape where speed in making decisions is a determining factor, these tools offer an important contribution.

It is possible to monitor all this, in addition to the local one, also in the cloud: a very interesting aspect as it is possible, through a simple browser, to visualize the result through any instrument connected to the network, from the smartphone to the tablet to the PC, you can always take a look at the data collected, all in real time!

Monitoring the activity of the press, having the information that we are always interested in, getting important alerts or messages useful for example for predictive maintenance, is an interesting plus even for the forging sector that now more than ever becomes intelligent and in step with market demands!

EMO 2019: We unveil the technology of the future!

Mecolpress is ready for EMO 2019, the most important metalworking machinery fair, in Hannover from September 16th to 21st.

Mecolpress has always participated in EMO, the leading trade fair for the metalworking sector.

At each edition we always present some innovations, and this year more than ever!

On the Mecolpress stand there will be the possibility to see 2 machines running!

1- THE BRAND NEW HEAVY 400

Mecolpress will officially present the new HEAVY series of continuous cycle eccentric presses at EMO2019!

Its main features are:

- an extremely innovative and modern structure, more robust and also designed with an eye to ease and accessibility for maintenance and to safety;

- we have completely renewed die automation and lubrication;

- we have mounted a special hydraulic cushion that enhances the ability to forge cored parts, as well as to strongly reduce vibrations and noise;

- as on all our presses, also on the HEAVY series is installed Calipso, the intelligent software of Mecolpress for the analysis of the production process and for predictive maintenance.

The Mecolpress HEAVY Series represents the state of the art in hot forging with eccentric presses and can mount all the most modern accessories, production, programming and control systems.

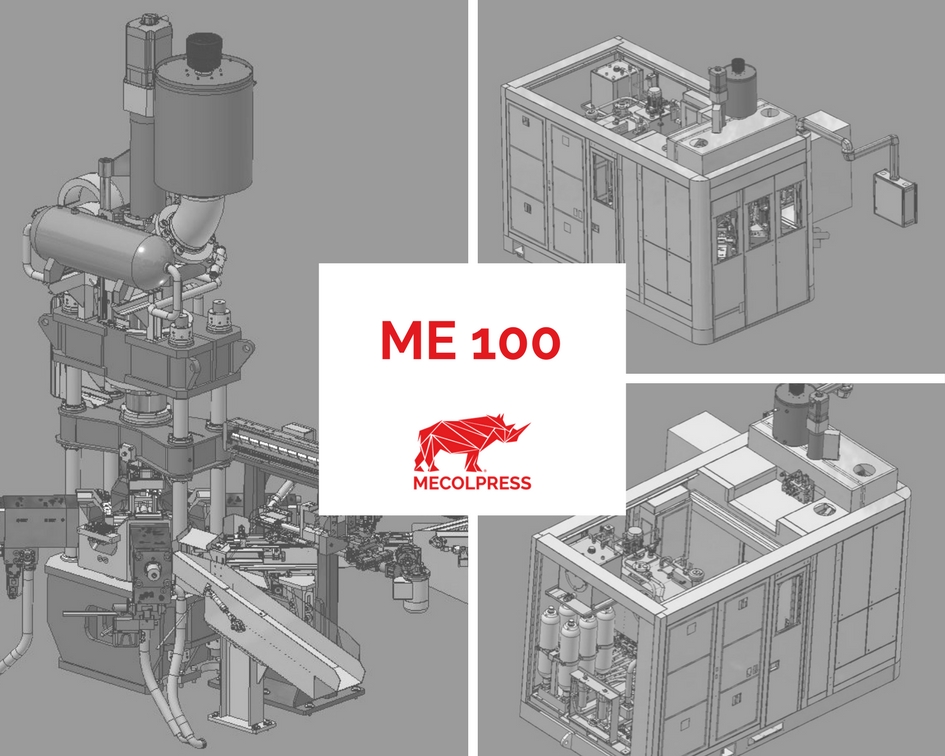

2- The ME100/4L30 superfast – high productivity hydraulic press.

It is a compact machine, dedicated to the forging of small complex pieces, with an extremely high productivity.

This machine is the latest model of the now known and appreciated Mecolpress ME hydraulic presses, installed all over the world, from Japan to Mexico, from Korea and from China to Germany and Italy.

ME hydraulic presses have been for years a real innovation in the world of hot forging. They allow printing without flash thus significantly reducing material waste.

The ME100 / 4L30, like all Mecolpress hydraulic presses, is equipped with a powerful statistical process control software developed by us, called Calipso.

As stated by the official Hannover Magazine, this year EMO will focus more and more on digitization, with many insights and eyes still on the subject of Industry 4.

Among the most interesting aspects of Industry 4.0 there is undoubtedly the development of the so-called “platform economies”, also Mecolpress in this regard will present a new way of experiencing hot forging machines: connected in the cloud the press becomes intelligent, smart and easily monitored!

We will demonstrate how it is possible to integrate our presses with cloud or local applications that allow to carry out analysis of multiple operating and process parameters, thus representing, through dashboards, a real-time visualization for an optimal understanding of the data collected by the machine.

We will present all this at EMO 2019,

follow the event on our social media channels, we will soon reveal important news!

The presence of Mecolpress at Korea Metal Week 2017

We are exhibiting at the Korea Metal Week show at the Kintex Exhibition Center in Seoul,

from 24th to 27th of October

As Korea’s leading international trade exibithion, Korea Metal Week offers the best market with the latest technology for suppliers, manufacturers and operators of the metal industry worldwide.

Korea Metal Week 2017 includes eight well organized fairs that integrate all metal production technologies.

Korea Metal Week, already established as the largest trade fair in the metalworking and machining sector in Korea, will be an important trading and sharing opportunity with hot forging industry from around the world.

Mecolpress will have its own booth at the show, and you can meet there the sales manager from the Italian headquarters and the Korea sales representative.

They will be glad to present to you the whole Mecolpress range of presses for hot forging of metals, with examples of real applications solutions.

It will be a great opportunity for you to learn the advantages that a Mecolpress Forging Line can offer to your company.

We look forward to see you there!

Mecolpress will attend

Korea Metal Week (Kintex Seoul – Korea)

from October the 24th to 27th.

We are at Booth 8A120

The new Hydraulic Press 4.0 technology Intelligent Manufacturing

Discover the Benefits of Intelligent Manufacturing with Mecolpress Hydraulic Presses - Technology 4.0

Returning from the EMO Fair in Hanover, our new hydraulic press ME 100.

Mecolpress has always been part of this event, and this edition has also been an important event for us, where we met many visitors from all over the world.

The digitization of industrial production has been the leitmotif across all Emo 2017 booths.

Industry 4.0 is a major process of global interest and also Mecolpress has presented its new ME100 hydraulic press, offering solutions for Industry 4.0 and integrated production.

La nostra nuova proposta è una pressa idraulica compatta SuperVeloce per la forgiatura di pezzi complessi a basso peso che assicura un altissimo livello di produttività, possibilità di stampare parti con forature multiple, forgiatura in singola o doppia figura, in verticale, in orizzontale e con ogni angolo billetta.

Our new proposal is a super-fast compact hydraulic press for the forging of low-weight complex parts that ensures a high level of productivity, the ability to forging multi-punched parts, forged single or double shape, vertically, horizontally and with each billet angle.

Mecolpress has developed this innovative machine, which will become part of the well-known series of presses ME, will have the code ME100-4L-30. This machine responds fully to our customers’ Industry 4.0 requirements and the general market for a press that features high precision features along with flexibility, ease of configuration and control of the production process.

Another important news was The brass bars heating+shearing furnace GBH5000, which allow great precision and modularity, in fact to connect both to new and existing presses, hydraulic, mechanical and screw.

Like all our ME series hot-press hydraulic presses, the new ME100 also allows you to control the speed, sequence, stroke and strength of each punch, enabling some of the most complicated forms to be forged flash-less.

The production phases are programmed and monitored to get the best shape.

Read more about the 4.0 requirements of our machines..

Mecolpress also puts you at your disposal a powerful production analysis software tool that allows you to perform statistical analysis of the forging process. This greatly reduces the waste of time and resources due to the production of non-conforming productions.

Read more about our software Calipso Statistical Process Control.

We are very pleased with the success of the news we have presented, but we are already committed to new extensions of our range of presses and also accessories for special applications. Follow us to stay up to date.

We thank all the visitors and the staff who took part in the event. We remind you of the next appointment:

The presence of Mecolpress at EMO2017

Mecolpress is constantly participating in EMO at every edition of this event, and this year will bring to the fair its most important innovations that will attract the interest of thousands of visitors.

Especially Mecolpress will show EMO2017 for the first time a newly conceived product, a compact hydraulic press for the forging of complex low-weight pieces that ensures a high level of productivity thanks to the different single or double forging solutions that ensures at each corner.

Mecolpress has developed this innovative product that will enrich the lucky series of ME presses ME100-4L-30, based on the many expectations of its customers and the market in general towards a work center that could present high-precision features along with flexibility, ease of configuration and control.

Other innovations that will be presented at EMO2017 are the GBH5000 stand-alone ovens that allow great precision and modularity, effectively connecting to both new and existing presses, hydraulic, mechanical and screw, of Mecolpress or any other manufacturer.

Where is Mecolpress at EMO2017

As with past editions, Mecolpress has a stand that is important and centrally located with respect to exposure.

Visitors can find Mecolpress at:

Booth E28 Hall 015

Emo 2015 - Milano

Emo 2013 - Hannover

What is EMO?

EMO2017 is the new edition of the world’s largest trade show of industrial machines and mechanical tools. EMO is held every two years alternately in Hannover, as it does this year, and in Milan where it was held in 2015 and where it will be held again in 2019.</span

All the major companies that manufacture and buy industrial machines and mechanical components in the world are participating in EMO, making this fair event the most important event of the industry for a long time.

The areas where the trade fair is divided are numerous, ranging from the most advanced machinery to mechanical engineering specialists, assembly tools, and software and accessories. EMO has always been the international event in which the latest innovations and inventions are announced in the field of mechanics.

The past edition of EMO in Hanover has counted nearly 150,000 visitors from over 110 countries around the world and has been set up over an area of more than 180,000 square meters, entrusted to more than 2,100 exhibitors who could count on a highly qualified clientele made up almost 99% by industry professionals.

The new hydraulic press with heating-cutting bars online

Presentation of new hydraulic press ME100 / 4L30 with with very high productivity,

Heated+Cutting Bar on-line

The new compact hydraulic press ME100-4L-30 dedicated to the forging of complex shapes with low weight, with extremely high productivity.

The new machine is an evolution of the well-known and appreciated Mecolpress ME hydraulic machines, installed and working all around the world, from Japan, through Korea and China, up to Germany and Italy.

Features:

- Multiples coring possibility, single or double shape forging (parallel or head-to-head), in vertical, horizontal and at any angle.

- Advanced motion solutions to grant highest speed and the most precise control.

- Designed with focus on fast set up and easy access, maintenance and cleaning.

The brass bars heating+shearing furnace GBH5000 is what the market is since long waiting for:

a bar heating furnace, that at the same time can shear into billets, built as a stand-alone unit.

Advantages:

– independent from the press, as furnaces have always been: can be connected to new or existing presses, hydraulic, mechanic or screw presses, and loading automation, of whatever brand;

– allow the user the best flexibility in the production organisation and company development;

– for all lengths of bars up to 5 meters;

– no problems with small diameters;

– no damaging of the brass grain structure because of long-time high-temperature heating.

We will preview the machine at EMO 2017, follow the event.

We expose to EMO 2017

Also this year Mecolpress will be present at the EMO exibithion, which will be held in Hannover from September 18 to 23 in the 2017 edition.

Participation in the exibithion will be an opportunity to share with all our customers and participants in the event the latest technological innovations on Mecolpress machines, which this year will be particularly numerous and interesting.

The Research & Development laboratory of Mecolpress has in fact released in 2017 a series of new configurations and solutions that will allow to realize further benefits from the point of view of precision and cost of production.

Mecolpress will present to the international customers of EMO 2017 an important news and will provide some advances in the coming weeks through this blog.