The new Hydraulic Press 4.0 technology Intelligent Manufacturing

Discover the Benefits of Intelligent Manufacturing with Mecolpress Hydraulic Presses - Technology 4.0

Returning from the EMO Fair in Hanover, our new hydraulic press ME 100.

Mecolpress has always been part of this event, and this edition has also been an important event for us, where we met many visitors from all over the world.

The digitization of industrial production has been the leitmotif across all Emo 2017 booths.

Industry 4.0 is a major process of global interest and also Mecolpress has presented its new ME100 hydraulic press, offering solutions for Industry 4.0 and integrated production.

La nostra nuova proposta è una pressa idraulica compatta SuperVeloce per la forgiatura di pezzi complessi a basso peso che assicura un altissimo livello di produttività, possibilità di stampare parti con forature multiple, forgiatura in singola o doppia figura, in verticale, in orizzontale e con ogni angolo billetta.

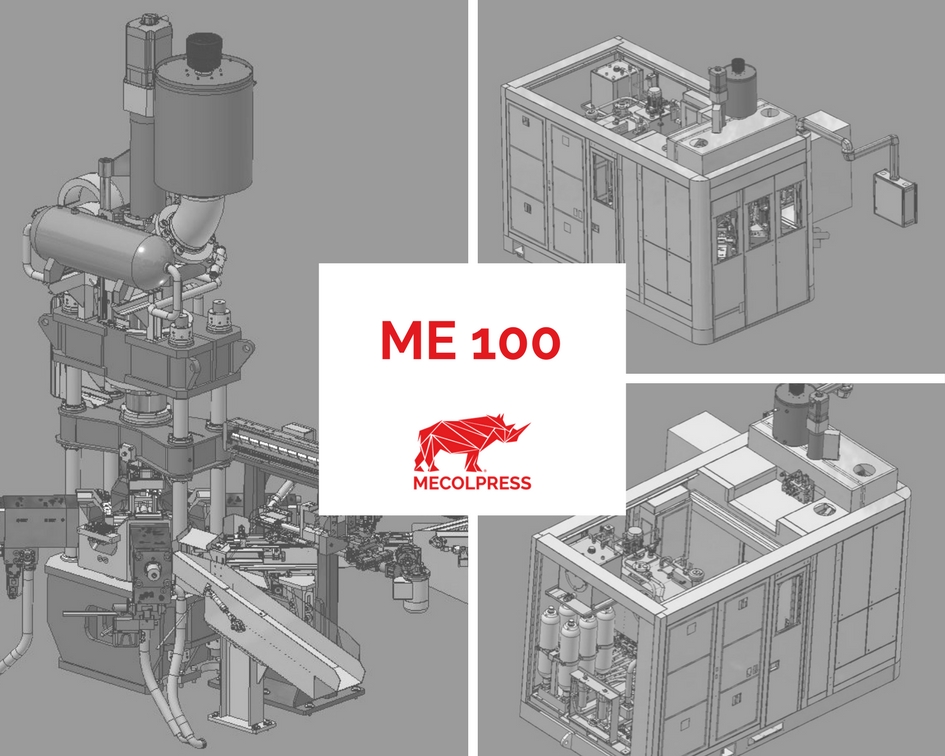

Our new proposal is a super-fast compact hydraulic press for the forging of low-weight complex parts that ensures a high level of productivity, the ability to forging multi-punched parts, forged single or double shape, vertically, horizontally and with each billet angle.

Mecolpress has developed this innovative machine, which will become part of the well-known series of presses ME, will have the code ME100-4L-30. This machine responds fully to our customers’ Industry 4.0 requirements and the general market for a press that features high precision features along with flexibility, ease of configuration and control of the production process.

Another important news was The brass bars heating+shearing furnace GBH5000, which allow great precision and modularity, in fact to connect both to new and existing presses, hydraulic, mechanical and screw.

Like all our ME series hot-press hydraulic presses, the new ME100 also allows you to control the speed, sequence, stroke and strength of each punch, enabling some of the most complicated forms to be forged flash-less.

The production phases are programmed and monitored to get the best shape.

Read more about the 4.0 requirements of our machines..

Mecolpress also puts you at your disposal a powerful production analysis software tool that allows you to perform statistical analysis of the forging process. This greatly reduces the waste of time and resources due to the production of non-conforming productions.

Read more about our software Calipso Statistical Process Control.

We are very pleased with the success of the news we have presented, but we are already committed to new extensions of our range of presses and also accessories for special applications. Follow us to stay up to date.

We thank all the visitors and the staff who took part in the event. We remind you of the next appointment:

The presence of Mecolpress at EMO2017

Mecolpress is constantly participating in EMO at every edition of this event, and this year will bring to the fair its most important innovations that will attract the interest of thousands of visitors.

Especially Mecolpress will show EMO2017 for the first time a newly conceived product, a compact hydraulic press for the forging of complex low-weight pieces that ensures a high level of productivity thanks to the different single or double forging solutions that ensures at each corner.

Mecolpress has developed this innovative product that will enrich the lucky series of ME presses ME100-4L-30, based on the many expectations of its customers and the market in general towards a work center that could present high-precision features along with flexibility, ease of configuration and control.

Other innovations that will be presented at EMO2017 are the GBH5000 stand-alone ovens that allow great precision and modularity, effectively connecting to both new and existing presses, hydraulic, mechanical and screw, of Mecolpress or any other manufacturer.

Where is Mecolpress at EMO2017

As with past editions, Mecolpress has a stand that is important and centrally located with respect to exposure.

Visitors can find Mecolpress at:

Booth E28 Hall 015

Emo 2015 - Milano

Emo 2013 - Hannover

What is EMO?

EMO2017 is the new edition of the world’s largest trade show of industrial machines and mechanical tools. EMO is held every two years alternately in Hannover, as it does this year, and in Milan where it was held in 2015 and where it will be held again in 2019.</span

All the major companies that manufacture and buy industrial machines and mechanical components in the world are participating in EMO, making this fair event the most important event of the industry for a long time.

The areas where the trade fair is divided are numerous, ranging from the most advanced machinery to mechanical engineering specialists, assembly tools, and software and accessories. EMO has always been the international event in which the latest innovations and inventions are announced in the field of mechanics.

The past edition of EMO in Hanover has counted nearly 150,000 visitors from over 110 countries around the world and has been set up over an area of more than 180,000 square meters, entrusted to more than 2,100 exhibitors who could count on a highly qualified clientele made up almost 99% by industry professionals.

The new hydraulic press with heating-cutting bars online

Presentation of new hydraulic press ME100 / 4L30 with with very high productivity,

Heated+Cutting Bar on-line

The new compact hydraulic press ME100-4L-30 dedicated to the forging of complex shapes with low weight, with extremely high productivity.

The new machine is an evolution of the well-known and appreciated Mecolpress ME hydraulic machines, installed and working all around the world, from Japan, through Korea and China, up to Germany and Italy.

Features:

- Multiples coring possibility, single or double shape forging (parallel or head-to-head), in vertical, horizontal and at any angle.

- Advanced motion solutions to grant highest speed and the most precise control.

- Designed with focus on fast set up and easy access, maintenance and cleaning.

The brass bars heating+shearing furnace GBH5000 is what the market is since long waiting for:

a bar heating furnace, that at the same time can shear into billets, built as a stand-alone unit.

Advantages:

– independent from the press, as furnaces have always been: can be connected to new or existing presses, hydraulic, mechanic or screw presses, and loading automation, of whatever brand;

– allow the user the best flexibility in the production organisation and company development;

– for all lengths of bars up to 5 meters;

– no problems with small diameters;

– no damaging of the brass grain structure because of long-time high-temperature heating.

We will preview the machine at EMO 2017, follow the event.

We expose to EMO 2017

Also this year Mecolpress will be present at the EMO exibithion, which will be held in Hannover from September 18 to 23 in the 2017 edition.

Participation in the exibithion will be an opportunity to share with all our customers and participants in the event the latest technological innovations on Mecolpress machines, which this year will be particularly numerous and interesting.

The Research & Development laboratory of Mecolpress has in fact released in 2017 a series of new configurations and solutions that will allow to realize further benefits from the point of view of precision and cost of production.

Mecolpress will present to the international customers of EMO 2017 an important news and will provide some advances in the coming weeks through this blog.

Mecolpress World Tour

Mecolpress exibithion

Mecolpress is active every year in sharing its expertise with the most important markets in the world.

In 2016 the new models of mechanical and hydraulic presses were presented, which have made the Mecolpress range evolve towards a higher integration of the production phases aimed at the highest efficiency and effectiveness of the work centers.

The Mecolpress presses were presented almost everywhere in the world at the most important events in the sector, as shown in the following illustration.

2017 is characterized by two even more important events: the two-year EMO fair that after the 2015 Milan event returns to Germany in Hannover and the presentation of a great novelty in the Mecolpress product line, which crowns almost fifty years of research and innovation with a family of new generation presses.

The 2017 fair program on the date is shown below.

Metalloobrabotka (Moscow) – 15-19 May 2017 – Pavilion 2 Hall 3 Booth 23B45

EMO Hannover (Germany) – 18-23 September 2017

Korea Metal week (Kintex) – 24-27 October 2017