With or without flash?

When you have to face a forging project for a new piece, the first step to take is to make a simulation by means of forging software and to decide whether to set the simulation with or without flash.

With or without flash?

Start with the forging simulation

In general terms we can affirm that thin-thickness pieces and material movements in different directions or with sudden dimension changes can give defects in flash free forging.

If the geometry is uniform and the section variations are contained, you can think of dealing with a flash free project.

It is true in all cases that starting a flash free project can allow evaluations that push to optimize the geometries of the piece (if it is possible to operate on the outer geometry) or it can drive the next analysis with flash.

A first flash free step involves certainly reduced calculation times and allows an evaluation of the punches forces and dies closure that can approximatively be considered valid in general.

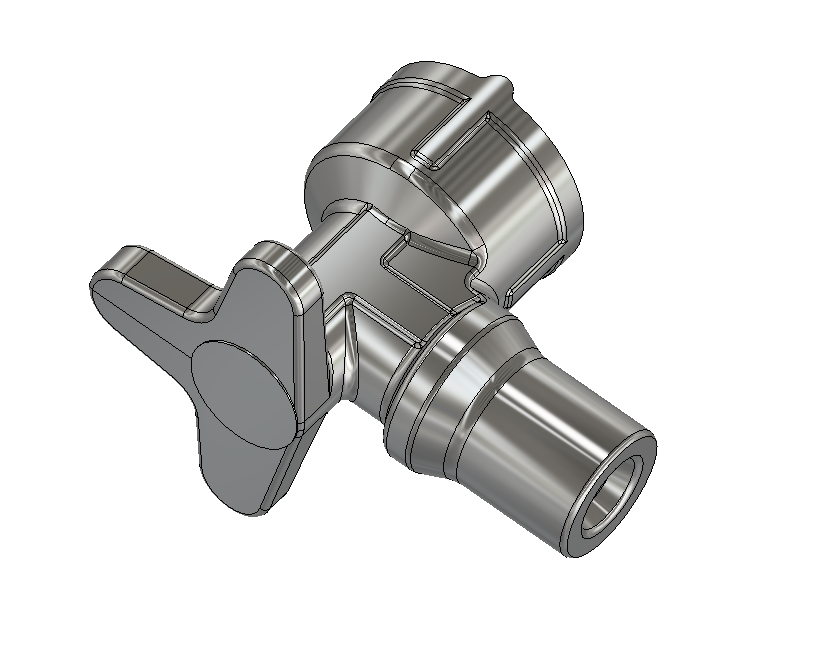

Suitable for forging with flash

Here above a geometry that very hardly is fit for a flash free forging

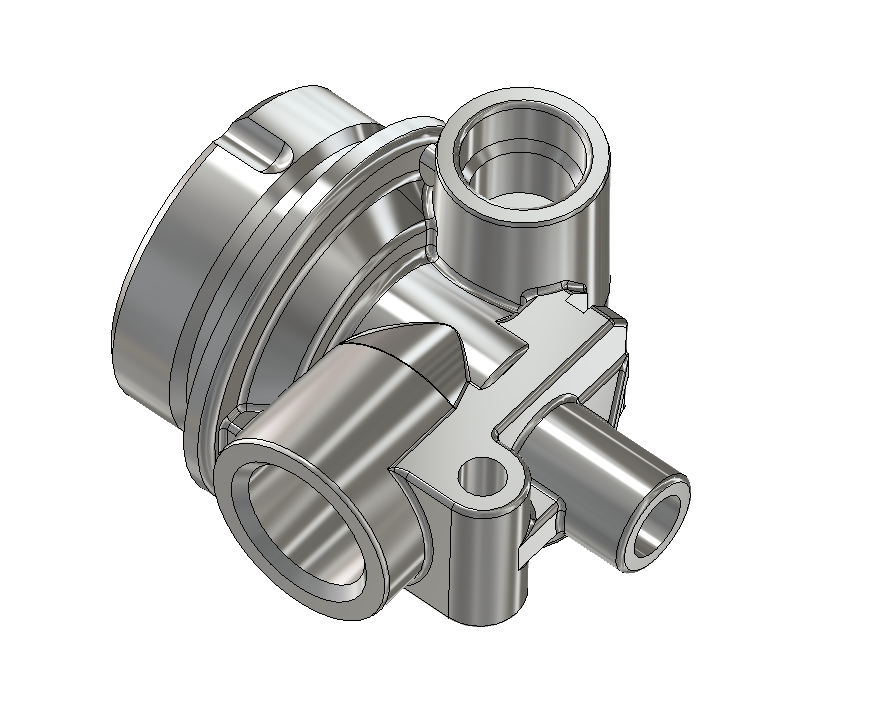

Suitable for flash-free forging

In this case, the success of a flash free project is very likely.

Is the press you have chosen suitable for forging your piece?

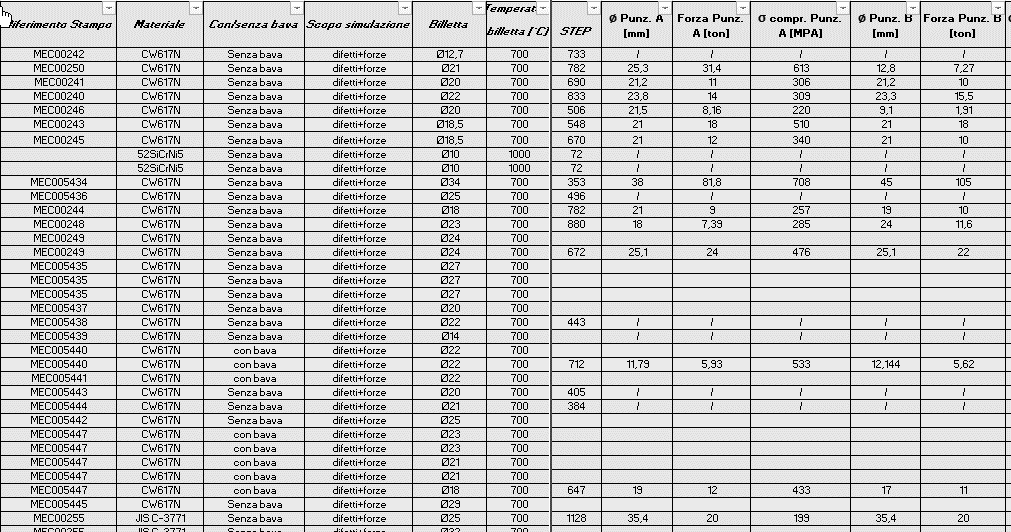

Secondly, it is necessary to roughly estimate if the analyzed piece is workable for the considered machine model.

At this stage you need to have a database showing the average pressures on half dies and on punches.

For this purpose, as the simulation history evolves, it is very useful to keep an Excel file in which the results in terms of forces are summarized in average pressures on half dies and punches.

This procedure allows you to understand at a glance if the result of a simulation can be considered valid or may be affected by calculation errors. Obviously, more cases are available more is likely to have reliable results, because the geometry of the piece strongly affects the force on each element of the die and therefore in the evaluation it is necessary to consider pieces with similar morphological characteristics.

Once the geometry of the piece is drawn, including the desired corings, it is necessary to obtain by subtraction the geometry of die and punches.

Firstly, however, the shape has to be scaled to take into consideration the fact that the formation occurs at a high temperature, while the drawing dimensions are valid for pieces at ambient temperature.

The typical brass value for forging is 1.012, while in the case of aluminum the factor 1.010 is generally used. With an Excel sheet, you can therefore estimate the diameter and length of the billet of first attempt.

For flash-free forging choose the hydraulic presses

Mecolpress hydraulic presses of ME series are the best solution for the forging of a part of brass, aluminum, or of other materials, without flash.

The closing force of the dies, higher than the one of the traditional mechanical presses, and the independent and controlled movement of the ram and of the extruders allow the hot forging of even complex parts without flash.

ME hydraulic presses have proved to be unbeatable in the forging of parts having some complexities.

For example, if you have to forge gate valves, our ME presses allow to forge these valves totally without flash, with very high precision, without the risk of defects caused by brass flow in the die.

In addition, even the production is higher compared to the one allowed by the traditional method with eccentric mechanical presses and with bell tool.

A ME350-4G240 hydraulic press, for example, can forge two-inch gate vales without flash, without the help of special tools, and with a productivity of about 800 parts/hour.

Another significant and practical example is that with a ME hydraulic press you can hot forge 4 brass parts at a time without flash!

Hydraulic Press ME100, the SuperFast!

Forge up to 60 pieces per minute without flash!

Our range of hot forging hydraulic presses ME has been enriched with the latest model ME100. It is a compact machine, dedicated to the forging of low-weight complex pieces, with extremely high productivity.

Mecolpress patented hydraulic presses, suitable for hot forging of standard and special brass or aluminium pieces.

This clamping force is higher than those of traditional mechanical presses. Independent & controlled movements of the ram and punches allow for flash-less hot forging also of complex pieces.

In addition to the ME150, ME250, ME350, we now also offer the ME100:

- 100 Tons of die closing force;

- 30 Tons for each of the punches (there can be up to 5)

- Forge in single or double figure, horizontally or vertically, and it is Super-Fast!

We tested it up to 30 strokes per minute and of course … it was promoted with full score!

As for all our ME hydraulic presses, the range of pieces that can be forged is very wide.

Here is a photo of typical brass parts that can be forged with this press:

Some info as an example:

– it can print ball valve bodies up to 3/4 inch, without flash (in single figure), or 1/2 inch in double figure.

– Accepts dies size 180x180mm.

– Punches stroke: 75mm.

Mecolpress has in fact the skills and the appropriate structure to make you ad hoc consultancy. Through the drawing of the piece you want to forge, we can perform a die simulation through the dedicated software in our internal technical office.

It will also be possible, if necessary, to carry out a real forging test of your piece thanks to the machines that we always have available at our company to carry out forging tests. We are thus able to offer you the machine, or the most suitable forging line for your needs.

And if the right press for you was not the ME100, we are always able to make the specific proposal for the needs of each customer, because Mecolpress has the widest range of hot forging presses of all!