SEO/320: THE MECHANICAL PRESS ADDRESSED TO THE MODERN FORGING

The new continuous and discontinuous cycle mechanical press

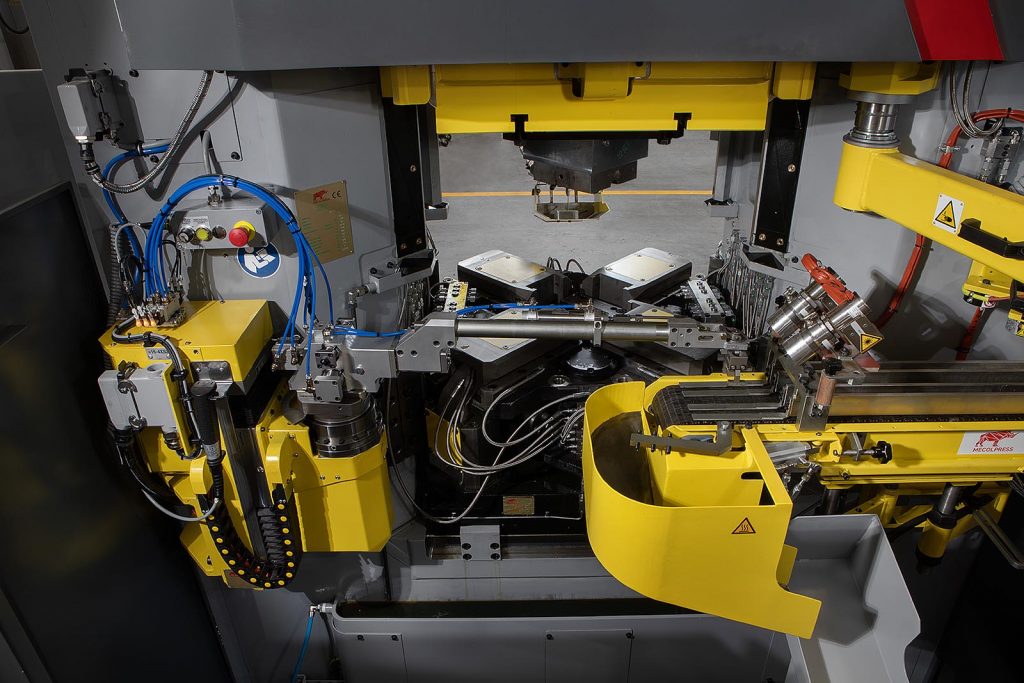

Mecolpress is proud to introduce the new model of continuous/discontinuous cycle mechanical press for hot forging, size 320 tons.

This press is designed to improve the features of all the previous machines in the size range from 200 to 360 tons. Finally just one single press will be able to guarantee the performances of the historical SEO/27 CVE-CS or SEO/36 CVE-CS presses, and it will be the new mechanical SEO/320 press, indeed!

The experience acquired in more than 50 years of activity brought us to analyze every day the forging needs of many worldwide Customers. The main topic that emerges is that the greatest force capacities are needed to deform new materials, high alloys\without lead that are considerably more high-strength.

The result is a totally innovative press that includes all the improvements that Mecolpress applied over the recent years.

SEO/320 press was born to satisfy all the new productive needs demanded by the ongoing changes in the world of “modern forging”.

Recurring problems for a forger

If you are a forge manager or an owner of a forging factory, it surely happened to you that, to satisfy your Customers request, you brought your presses to the higher limit of the performances. Consequently one of the following situations will surely happened at least one time::

- breakage of the gears, and in particular of the teeth;

- breakage of the transmission shafts;

- maintenance on bearings and clutches….

Forcing you to unexpected machine stops, with all the related inconveniences\additional costs!

Solutions proposed by Mecolpress

Machine downtimes cannot totally disappear. We must remember that we are talking about mechanical presses that forge metals at very high temperatures and that can be subjected to overloads! But these can be drastically reduced.

”Why often we say that years ago the machines did not break down?”

The answer is easy! They were sized and studied specifically for the productive needs of that time that do not coincide with the modern ones any longer!

Mecolpress answer to the new required performances in the forging operations is the new SEO/320 press that is what each forger needs today!

Technical characteristics of mechanical press SEO/320

- The machine has a monolithic structure in welded steel in order to ensure the maximum stability and duration over the year.

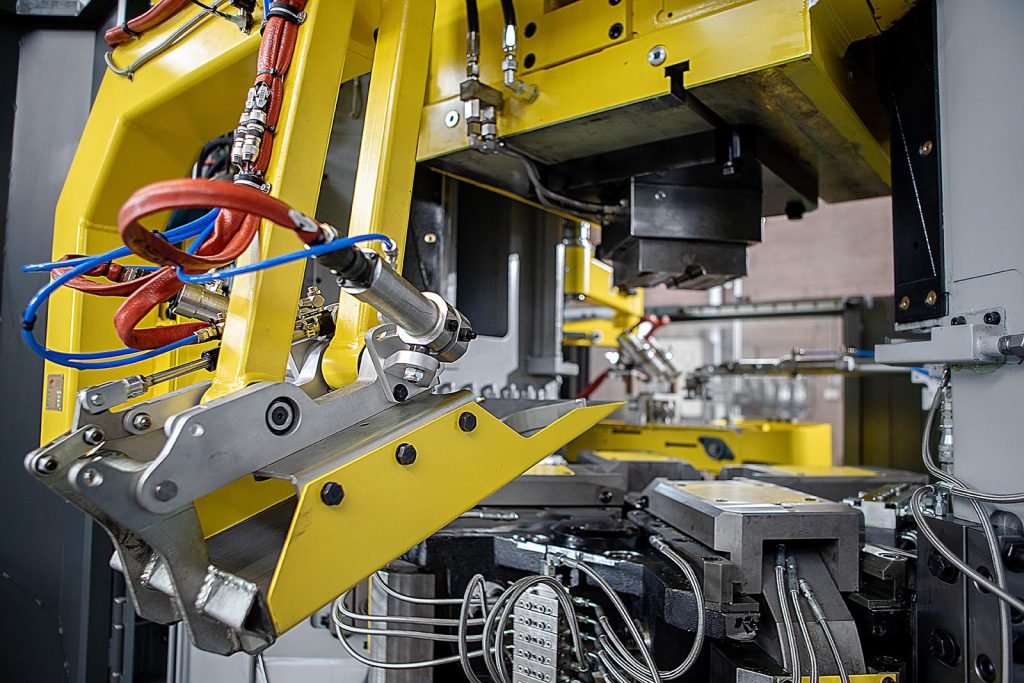

- The gears have a total innovative structure and extremely simplified that does not consist only in the dimensions increase, as you might think, but it consist of a series of improvements that allow the machine to work to the maximum performances without any breakage risk.

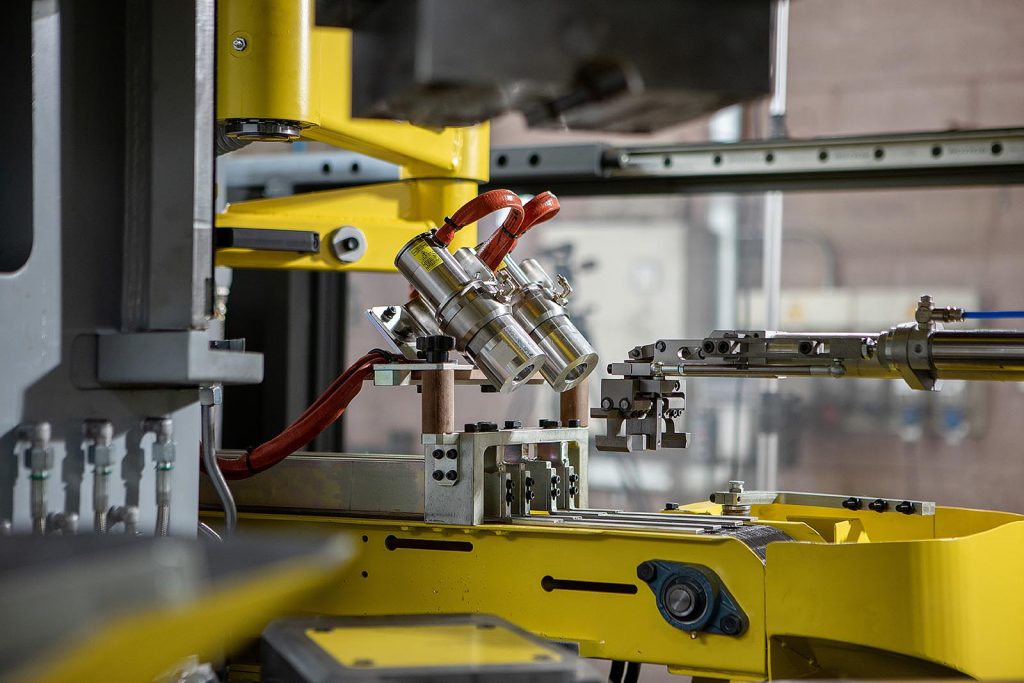

- The cushion was simplified, with the removal of the manual adjustments and of the mechanical parts generally subjected to wear.

- The flywheel was developed to guarantee enough deformation energy even at low turns. This particular characteristic is very appreciated by who has to forge the material requiring low deformation speeds.

- We have paid close attention to the ergonomic aspects: the operator can set up the tooling of the machine very quickly and without excessive efforts. Therefore you will find the equipment without tight spaces with wide visibility and, above all, safe and reliable.

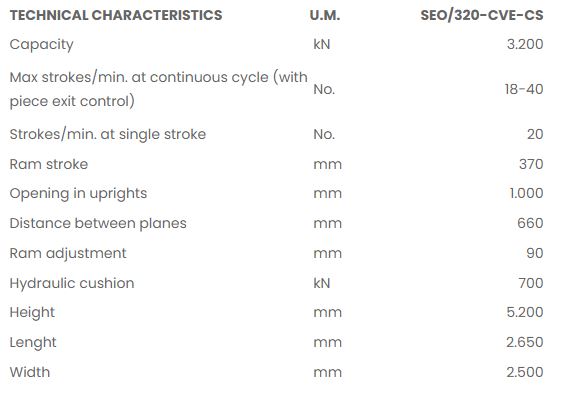

We summarize in the following table the main technical characteristics of the new SEO/320:

An opportunity for the forgers

Mecolpress offers to every potential customer the possibility to inspect at least one version for each machine model at the production site based in Flero (Brescia). As a matter of fact, the main versions of the most requested models are always in production.

This results in an important advantage for you Customer because we are offering:

- the opportunity to see/experience the new machines with the support of our specialized personnel at your disposal to clarify any doubts or curiosities;

- A very competitive delivery time In case of purchase!