HOT FORGING PRESSES INTERVIEW WITH MECOLPRESS

Company manufacturing hot forging presses.

We report an interview of the digital magazine Easy Engineering of 28 April 2020.

Established in 1969, MECOLPRESS was founded as a manufacturing company of mechanical presses for brass components hot forging. Up to today, Mecolpress has developed and installed more than 1.950 presses, at over 400 customers all around the world, used for forging brass, aluminum, copper, titanium, steel. The current production site in Flero, in the highly productive area of Brescia, takes up a 30.000 square meters surface, 10.400 of them are covered and employees 55 people, reaching a turnover in 2018 of 11.5 million Euro.

In 2019, in occasion of EMO exhibition in Hannover, Mecolpress officially presented the new series of continuous and discontinuous cycle eccentric presses, the HEAVY series.

Easy Engineering: What are the main areas of activity of the company?

MECOLPRESS: At the beginning all efforts were concentrated on brass hot forging field; in the time, also through the acquisition of the historical brands Osterwalder and Dellavia in the screw presses section, the variety of machines that we design and produce is now so wide and complete to satisfy the most different requirements of the customers: for each specific material, shape and quantity to be forged, we are in the position to offer the most suitable solution.

Mecolpress is today the only company among the manufacturers of presses for the hot forging of brass, aluminum steel, copper, titanium, with a so complete production program.

Our present production program consists of:

- TDS: direct drive with electrical servomotor;

- Dellavia and Osterwalder: Traditional disc friction.

PG Knuckle joint presses

for calibration and coining of parts.

Presse Meccaniche Eccentriche

- SOV and SEO/F: for the vertical hot forging;

- SEO and HEAVY: for forging with horizontal cores, in single or continuous cycle.

for forging brass and aluminum parts without flash.

- PO: single station;

- S: multiple station, rotary table with hydraulic motor;

- E: multiple station, rotary table with electric motor.

In addition, Mecolpress is particularly active in after-sales service. The heart and pride of Mecolpress is its large spare parts warehouse, which is able to supply accessories or spare parts for machines produced fifty years ago. For this reason, in addition to the sale of machinery, there is a wide activity related to the service and supply of accessories (such as tools, arms, spare parts, etc..).

E.E: What’s the news for 2020 about new products?

MECOLPRESS: At the end of 2019 Mecolpress presented at EMO fair in Havvore a brand-new series of eccentric presses, named HEAVY, which defines a new standard for the hot forging of brass.

A machine concept that offer highest durability and reliability together with an innovative software system that allows the maximum control on the process and the a very easy operation.

E.E: What are the ranges of traded products?

MECOLPRESS: As a manufacturer with an own wide range of products, the additional equipment that we simply trade is limited to ancillary machines, to offer complete forging lines (delivering a finished part from the input of a raw material bar) to those customer that prefer to have a turn-key plant from one source.

Typical traded machines are: billets heating furnaces, forging dies, sand blasting machines.

E.E: At what stage is the market where you are currently active?

MECOLPRESS: Since our machines are dedicated to a very wide panorama of applications (from house building to automotive, from gas control to biomedical) there are always new developments in these sectors.

This is for us very stimulating because we are constantly involved in the design of new solution, to support our customers with the most suitable equipment to manufacture parts that are chancing in the shapes, in the alloys and in the technical requirements.

E.E: What can you tell us about market trends?

MECOLPRESS: In the past our customers were mainly subcontractors, producing many different kinds of parts for the most differentiated OEMs. We see now more and more companies that are interested in bringing back into their own activity the hot forging process, to have full control over the entire production line. And also, the subcontractors that still exists, are increasing in size, in capability, and in specialization: they are requested to be much more accurate, reliable, more flexible and fast in changing production and technologies.

For these reasons, the machines that both our customer types (the subcontractors and the OEMs) need, are machines that can easily switch from one application to the next, and that can record and control really in depth every aspect of the production process. The user is therefore becoming more an engineer, that study and program the process in advance and then let the machine run autonomously, instead of an operator that has to stay full time at the machine, checking and adjusting the settings.

E.E: What are the most innovative products marketed?

MECOLPRESS: As above indicated, one of the most innovative products that we offer today is the new range of Heavy presses.

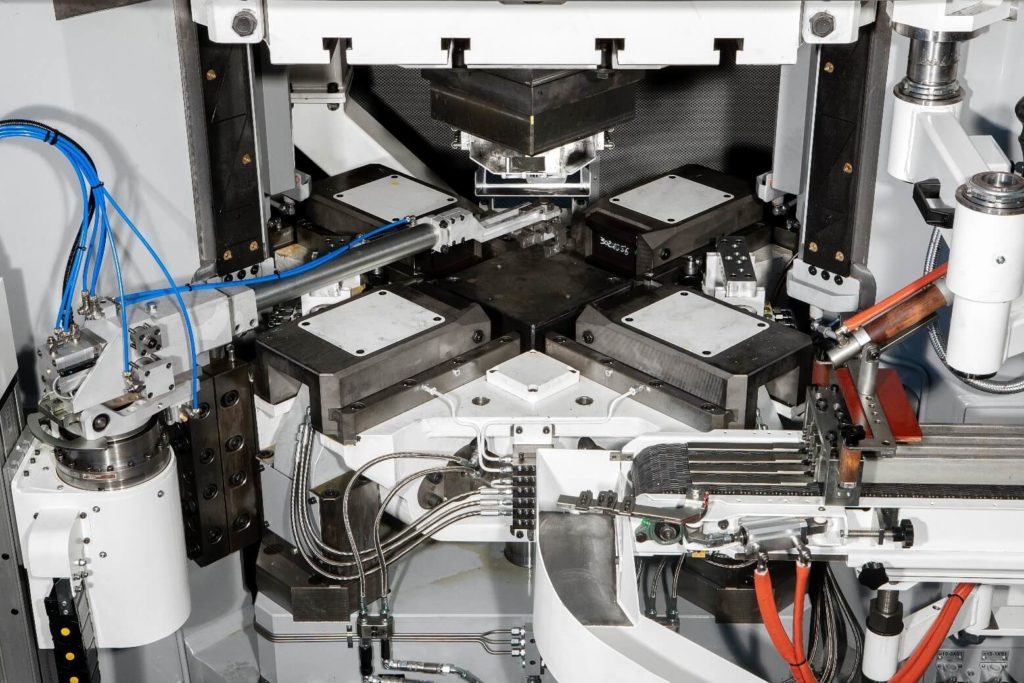

In parallel to this, we are widening the offer for the ME hydraulic presses which are designed to forge net shape parts. These machines are extremely versatile, can communicate in two directions with the company ERP software to exchange production data, recipes, preventive maintenance information. And are also able to automatically detect a non-conforming product and separate it from the good ones. This makes the ME forging presses a fully automatic system, that does not require operators to work but also does not need regular presence of quality control staff to check periodically the output.

E.E: What estimations do you have for 2020?

MECOLPRESS: At the end of 2019 we planned a very aggressive budget of sales for the 2020, and supported it with several activities and strategies, from the participation to many international shows, to the production of machines for stock, to grant to our customer very fast deliveries.

Unfortunately, due to the Covid-19 virus spreading, many commercial activities had to be reprogrammed or postponed. We are now investigating the world markets to assess what will be the customers’ propensity to invest for the remaining months of this year. We are very optimistic that we will in any case be able to reach most of our targets also thank to the availability of machines in our workshop, which is allowing us to complete deliveries in this year of machines ordered in the second and third quarter.

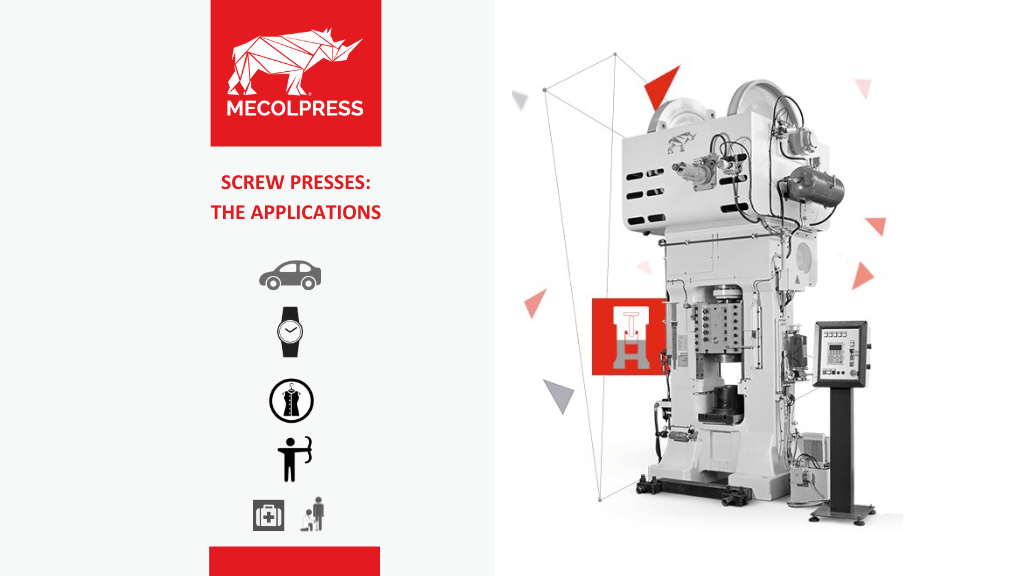

Screw presses

Come to discover the application sectors and the functioning of Mecolpress screw presses. Used for hot forging, these presses can be employed with every type of material and are distinguished by the realization of full parts.

Screw presses functioning

Mecolpress offers a wide range of presses both hydraulic and mechanical. Also screw presses fall into this last category, ideal for hot forging of parts of great dimensions or that require more passages for shaping. These mechanical screw presses can be provided with a disc friction control or a direct control with electric servomotor.

The screw press choice is determined according to the type of part you want to forge. Hallmark of the screw press is its ratio force-machine dimension, that results greater than the specific one of an eccentric mechanical press.

These mechanical presses can be used with every type of material and the frequency of strokes is quite reduced. For this reason, there is a tendency to use this machine for the production of little batches, that is often true for parts of great dimensions.

Mecolpress offers to its customers three lines of screw presses: Dellavia series and Osterwalder series that are friction screw presses, and TDS series with electric motor. All the screw presses models can be integrated with complete and automatic forging lines, that from bar raw material realize finished forged parts.

The tonnage can go from 170 tons up to more than 2.700 tons, to be chosen according to the geometrical shape you want to obtain and of course to the material to be forged.

The applications

The screw presses are used for the realization of parts destined to different application fields including for example, watch cases, parts for sport equipment, for automotive or for biomedical titanium prothesis.

So, it is possible to produce very small parts, such as for example, clothing zipper pullers till to aluminum sport bows of 1 m of length. The parts, produced by this type of machine, are not cored but full.

The screw presses are very used also in the fashion field to realize belt and bag buckles, with brand-specific shape.

In order to understand which model is more suitable to your production needs, all you have to do is to address to Mecolpress sales department. Thanks to the experience gained with years of activity in the hot forging field, we can suggest the most performing machine according to the type of part you want to forge, and it is possible to carry out a test directly at our premises.