Calipso Software

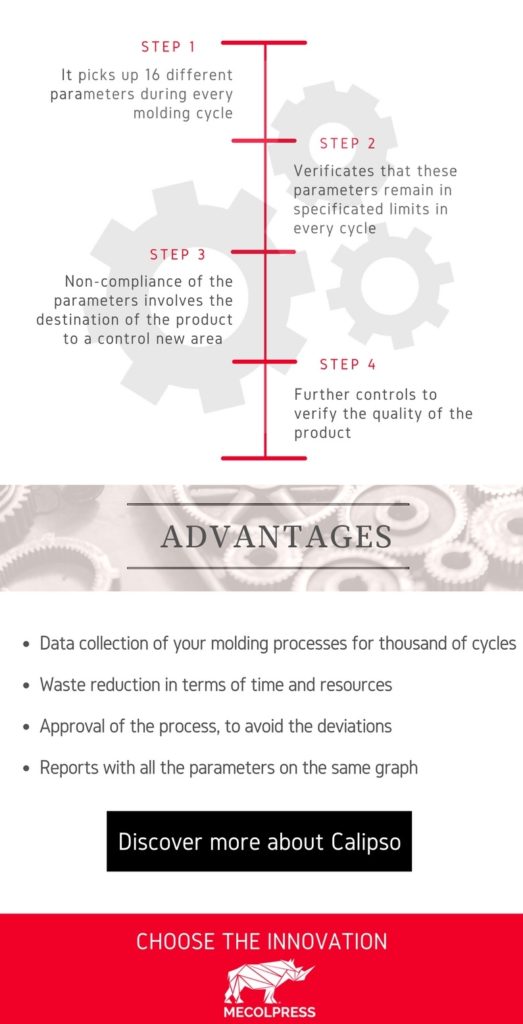

The Mecolpress Calypso System is a powerful software instrument that, thanks to a network of specific sensors and transducers on the press, collect up to 16 different parameters during each single forging cycle, all day long.

The recorded data are compared with the values set by the operator, for each of these it is checked that they stay inside a tolerance range (the width if which is decided by the operator) and in case one of these parameters in one cycle should result to be too different from what we had verified being the desired value, the piece forged during that specific “irregular” cycle is discharged in a separate area, to allow further controls.

In addition, the operator can program the system when this has to interrupt the automatic cycle production, after how many rejected pieces the machine shall suspend the production and wait for a human decision before to restart.

To go back to Einstein statement mentioned in the previous article, to be sure to do what I always did, and exactly in the same way I did it, I need an extremely reliable and precise process control and data collection system, and I also have to have an evaluation instrument of the collected data that allow me to have a true picture of how the forging cycle is performed, so to lead me to take decisions on the basis of reliable information.

Mecolpress Calypso does not only collect the typical data of the forging process for thousands of cycles, but create as well graphical representations of more than one parameter on the same graph to understand, for example, how the punches forward force is changing depending in relation with the billet temperature, and for all parameters show the variation trend over the time.

Mecolpress presses for the hot forging of metals are offering to you a production cycle analysis instrument that allow you the statistical forging process control, helping you to foresee when irregular deviation from the “nominal” process will arise, so that you can anticipate them and avoid that time and resources go lost in producing irregular parts and in sorting the good and the bad ones from a single container.

SPC CALIPSO

From Wikipedia, :

“Statistical process control (SPC) is a method of quality control which uses statistical methods. SPC is applied in order to monitor and control a process. Monitoring and controlling the process ensures that it operates at its full potential. At its full potential, the process can make as much conforming product as possible with a minimum (if not an elimination) of waste (rework or scrap). SPC can be applied to any process where the “conforming product” (product meeting specifications) output can be measured. Key tools used in SPC include control charts; a focus on continuous improvement; and the design of experiments. An example of a process where SPC is applied is manufacturing lines.”

How to translate in simple words the concept of Statistical Process Control?

Albert Einstein was saying:

“If we keep on doing what we always did, in the same way we always did it, we will always get the same result”.

The great physician used this statement to suggest the need of innovating, of thinking in a different way. But at the same time, we can have a fully positive interpretation of this principle: to be able to repeat a successful process exactly in the same way it was done previously, will certainly deliver again as good as the previous ones.

Let us transfer the concept in our world, the hot forging of metals. Here is an example:

If with a forging cycle we have obtained parts that, after dimensional, aesthetical and quality testing, are verified to be perfectly complying with the order prescriptions, it is highly possible that the next cycles, if repeated exactly with the same parameters, will lead to the same production result.

- software calipso di Mecolpress

During a component hot forging cycle process, there are so many parameters that can influence the result and therefore the quality of the produced parts and that are peculiar of that specific cycle, among these are:

-

- Temperature of the billets,

- die closing force,

- force applied by the coring punches,

- total cycle time,

- stroke of the punches,

- speed of the punches,

- weight of the unloaded forged piece…

Read more about Calipso Software