Are you doubtful between mechanical press and hydraulic press?

Are you doubtful about the press to choose? Mechanical press or hydraulic press?

Ask to Mecolpress, you will have no more hesitations!

You have just got a new commission and you need a new press for hot forging. Are you sure that you can identify the press that best suits your needs?

Typical request

It often happens that a Customer, or potential one, comes to us with the part he desires to forge. Usually it’s about complex situations, very far from standard applications. That’s exactly why the Customer asks for our help and support.

If the Customer is not a newcomer in the forging world, he usually arrives in Mecolpress with clear and straight idea about the type of press he wants. But very often it happens that he will change his view after having the possibility to get in contact with our forging know-how!

You ask for a mechanical press but you need an hydraulic one!

For example, some weeks ago two different customers came to visit us bringing some sampling to be forged. They were sure to ask a quotation for a mechanical press, they realized instead that the right machine for their situation was a hydraulic one!

Both our customers had the chance to test new dies, only 4 hours were needed for the preparation and installation of the dies and to run some tests. Even though the furnace was not the best one for their kind of production, because it’s a furnace that Mecolpress uses for testing, the machine gave a flash-free part in only 4 hours, with a saving of about 30% of material and with a quality definitely superior than the one they could achieve using a mechanical press.

Moreover, it is important to take into consideration the limits of the mechanical press:

- Since the part is not balanced, the mechanical press should use all its possible force to forge it.

- Working in this way the risk to run into damages or machine breakdown becomes greater.

On the contrary, The ME hydraulic press can forge the part better. The forged parts which required more force used however less than 200 tons on a punch, therefore it consists of a forces distribution that is totally different compared to the traditional mechanical press.

Often the customer is skeptical towards the hydraulic press, but just because he is not familiar with it!

Find out more about the hydraulic presses

The hydraulic presses patented by Mecolpress are suitable for the hot forging of standard parts or special parts in brass and aluminum. The dies closure force is higher than the one of the traditional mechanical presses and the independent and controlled movements of the ram and of the extruders allow to hot forge also complex parts without flash.

These are oleodynamic presses provided with coring tools combinable till to a maximum of 5 punches (4 horizontal and one vertical) suitable for the hot forging of brass, aluminum, copper and other materials.

Compared to the traditional mechanical presses these presses have different advantages, including:

- Reduced vibrations and noises.

- No foundations are required.

- Higher flexibility: there are no mechanical connections between tooling and ram; this implicates that you can decide speed, force, position and movement sequence for each punch independently. The result is the possibility to decide how to let the material flow, this helps the part production with a better quality level.

- Ease of tooling: easy access to the forging area and automatic adjustment of punches strokes from the panel that cancels the mechanical adjustment on the spines (for example insertion of spacer).

- The press is easy and intuitive to be used even without a great experience in the forging field. Together with the machine a lifelong service via teleservice and phone assistance is provided.

Some practical examples about the choice for a hydraulic press.

- Hydraulic press ME150: this is a quite small machine and often we suggest it to who has no experience in the hot forging field.

- Hydraulic press ME 250: let’s get serious!

Example: are you undecided if you want to buy a 400t mechanical press or a ME250 hydraulic press?

If you have small and easily to force parts to be produced in huge quantities and in series maybe the choice of a mechanical press is the most suitable, but if you have a part that is lightly more complicated, probably you need an hydraulic one. In this case, we are sure that a test here in Mecolpress will remove any doubt!

- Hydraulic press ME from 450tons onwards: This press is more efficient, more cost-effective, it allows to save material, to increase the productivity, it is more convenient, more silent, no foundation pit is required and despite of what our competitors affirm, the energy consumption is not high. In fact, this consideration comes from the fact that just the installed power is taken into consideration.

Did you carry out a forging simulation and forging tests?

In order to choose the right press it is surely helpful to carry out a forging simulation, our technical office can support the customer during the process for choosing the machine with a software analysis of material flow, in order to carry out a sort of “virtual pre-acceptance” of the plant.

Once that the forging simulation is successfully over, then the next step is a real test in our factory. Indeed we have available machines devoted for the forging tests, this is a very important aspect for the customer that often gives him the possibility to invest in a more aware and motivated way. Touching the forged part doesn’t leave no room for doubt!

Being able to satisfy and fully understand the customer needs, to demonstrate and propose our most suitable solutions with concrete tests thanks to the machines and toolings we have available in Mecolpress for the forging tests is for us matter of pride.

Hydraulic Press ME100, the SuperFast!

Forge up to 60 pieces per minute without flash!

Our range of hot forging hydraulic presses ME has been enriched with the latest model ME100. It is a compact machine, dedicated to the forging of low-weight complex pieces, with extremely high productivity.

Mecolpress patented hydraulic presses, suitable for hot forging of standard and special brass or aluminium pieces.

This clamping force is higher than those of traditional mechanical presses. Independent & controlled movements of the ram and punches allow for flash-less hot forging also of complex pieces.

In addition to the ME150, ME250, ME350, we now also offer the ME100:

- 100 Tons of die closing force;

- 30 Tons for each of the punches (there can be up to 5)

- Forge in single or double figure, horizontally or vertically, and it is Super-Fast!

We tested it up to 30 strokes per minute and of course … it was promoted with full score!

As for all our ME hydraulic presses, the range of pieces that can be forged is very wide.

Here is a photo of typical brass parts that can be forged with this press:

Some info as an example:

– it can print ball valve bodies up to 3/4 inch, without flash (in single figure), or 1/2 inch in double figure.

– Accepts dies size 180x180mm.

– Punches stroke: 75mm.

Mecolpress has in fact the skills and the appropriate structure to make you ad hoc consultancy. Through the drawing of the piece you want to forge, we can perform a die simulation through the dedicated software in our internal technical office.

It will also be possible, if necessary, to carry out a real forging test of your piece thanks to the machines that we always have available at our company to carry out forging tests. We are thus able to offer you the machine, or the most suitable forging line for your needs.

And if the right press for you was not the ME100, we are always able to make the specific proposal for the needs of each customer, because Mecolpress has the widest range of hot forging presses of all!

Why to choose Mecolpress presses?

Mecolpress makes available to its customers quality presses and all its technologic know how. For those who need high performing machineries for hot forging we are a reliable and with a solid experience partner in this field, gained in many years of activity.

Whether it is an entire forging line or a single machinery, Mecolpress can suggest the most performing solution for production and offer a technical support able to face every need.

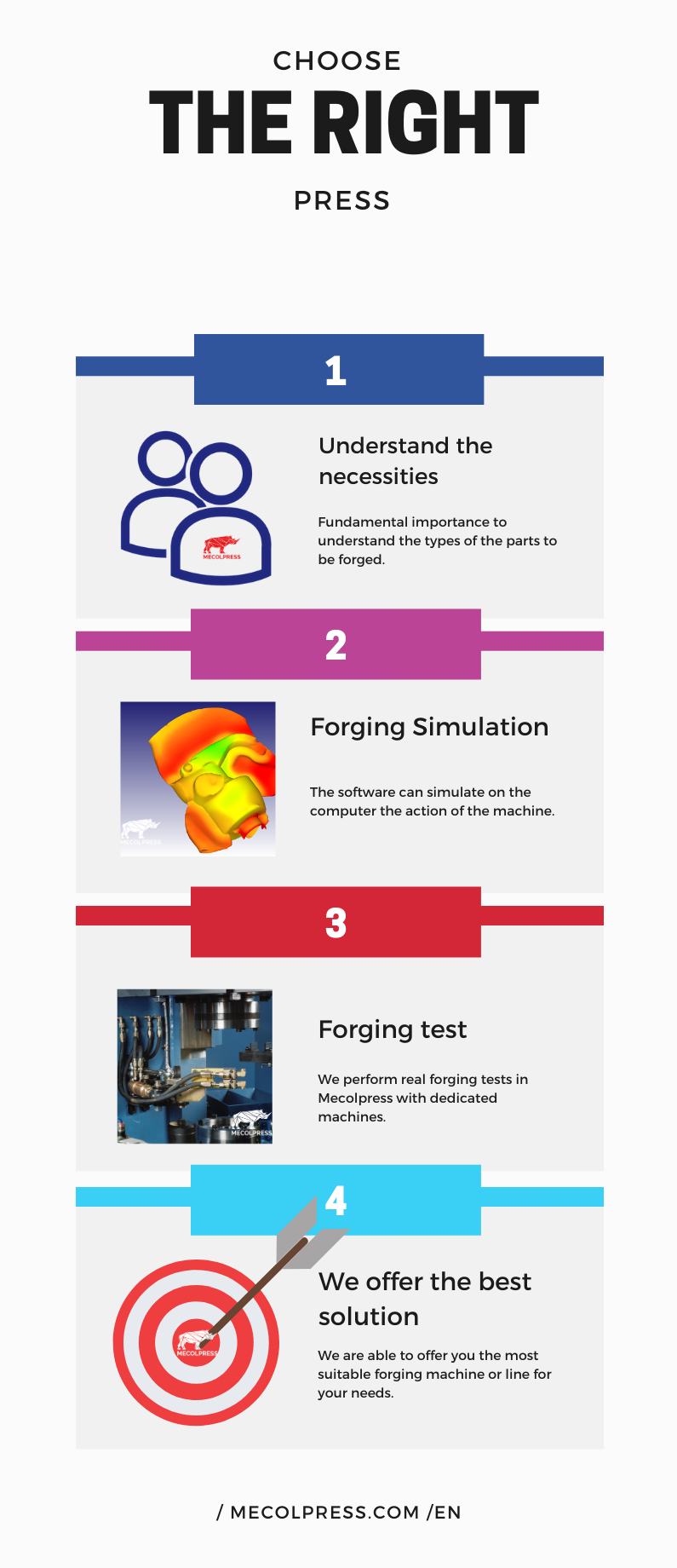

A first meeting to understand the necessities

When a new potential customer contacts us expressing its need to buy a press, our sales department organizes immediately a first meeting either at customer’s or at our premises in order to show the different machines and their functioning.

During this phase, to us it is of fundamental importance to understand the types of the parts to be forged and which could be the eventual criticalities connected to the single parts in order to be able to propose the most suitable press. In many cases our offers are based directly on the drawings of the parts to be forged that are analyzed by our technical office in great details.

In order to understand which is the best press, our technical office takes advantage of a software that can simulate on the computer the action of the machine. In this way we provide a valid tool for the identification of the machinery that meets the productive needs.

Some customers in addition to the single press require the entire hot forging line and, in this case as well, we can provide all the necessary machineries, and to optimize the production.

Forging tests at Mecolpress

Once the most fitting press for the customer has been identified, even if this is hydraulic or mechanical, we carry out forging tests at our premises. So, the customer can be sure in advance of the final result before starting the production at his premises.

In order to carry out the test, the dies for the realization of the wished parts are mounted on the machine. In case the customer does not have the die, there is the possibility to commission it directly to Mecolpress. Indeed, our company offers a complete service to support the customer during all the productive steps and can also offer this component.

During the many years of activity we have gained high technical skills and we have confronted with different situations. The gained experience has turned us into a partner that can understand the forgers needs, able to propose mechanical or hydraulic press for a specific production type.

EMO 2019: We unveil the technology of the future!

Mecolpress is ready for EMO 2019, the most important metalworking machinery fair, in Hannover from September 16th to 21st.

Mecolpress has always participated in EMO, the leading trade fair for the metalworking sector.

At each edition we always present some innovations, and this year more than ever!

On the Mecolpress stand there will be the possibility to see 2 machines running!

1- THE BRAND NEW HEAVY 400

Mecolpress will officially present the new HEAVY series of continuous cycle eccentric presses at EMO2019!

Its main features are:

- an extremely innovative and modern structure, more robust and also designed with an eye to ease and accessibility for maintenance and to safety;

- we have completely renewed die automation and lubrication;

- we have mounted a special hydraulic cushion that enhances the ability to forge cored parts, as well as to strongly reduce vibrations and noise;

- as on all our presses, also on the HEAVY series is installed Calipso, the intelligent software of Mecolpress for the analysis of the production process and for predictive maintenance.

The Mecolpress HEAVY Series represents the state of the art in hot forging with eccentric presses and can mount all the most modern accessories, production, programming and control systems.

2- The ME100/4L30 superfast – high productivity hydraulic press.

It is a compact machine, dedicated to the forging of small complex pieces, with an extremely high productivity.

This machine is the latest model of the now known and appreciated Mecolpress ME hydraulic presses, installed all over the world, from Japan to Mexico, from Korea and from China to Germany and Italy.

ME hydraulic presses have been for years a real innovation in the world of hot forging. They allow printing without flash thus significantly reducing material waste.

The ME100 / 4L30, like all Mecolpress hydraulic presses, is equipped with a powerful statistical process control software developed by us, called Calipso.

As stated by the official Hannover Magazine, this year EMO will focus more and more on digitization, with many insights and eyes still on the subject of Industry 4.

Among the most interesting aspects of Industry 4.0 there is undoubtedly the development of the so-called “platform economies”, also Mecolpress in this regard will present a new way of experiencing hot forging machines: connected in the cloud the press becomes intelligent, smart and easily monitored!

We will demonstrate how it is possible to integrate our presses with cloud or local applications that allow to carry out analysis of multiple operating and process parameters, thus representing, through dashboards, a real-time visualization for an optimal understanding of the data collected by the machine.

We will present all this at EMO 2019,

follow the event on our social media channels, we will soon reveal important news!

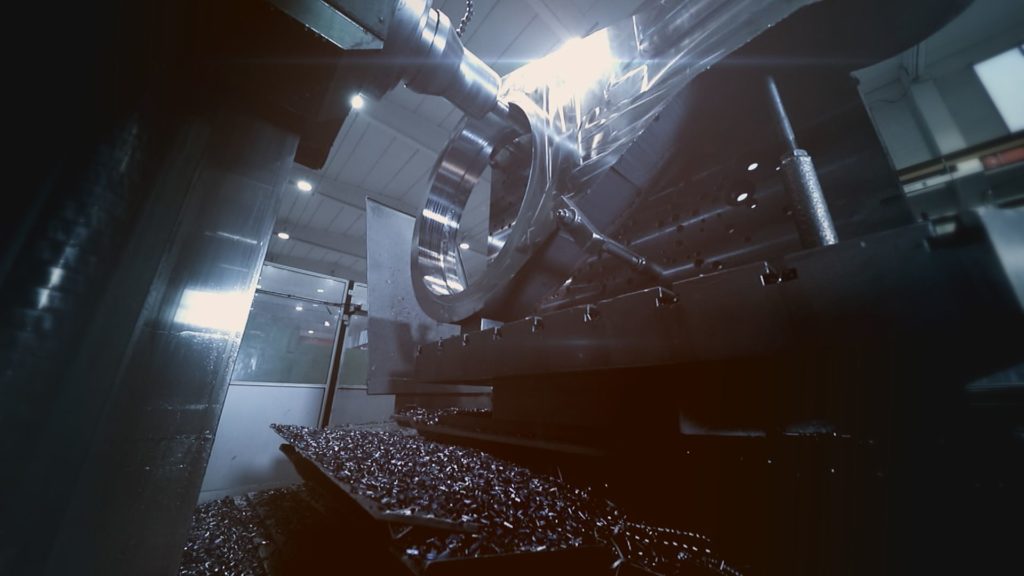

Hot forging and titanium machining

Titanium is a particular resistant material, often used for hot forging. Mecolpress proposes furnaces and both hydraulic and mechanical presses suitable for the forging of titanium alloys of parts destined to different application sectors.

Mecolpress offers to its customers a wide range of presses for titanium hot forging and our sales department is always ready to offer a customized advice to suggest the best machinery according to the used alloy to forge and to the type of geometry the customer wants to obtain.

Titanium features

Titanium is lighter and much more resistant than steel: for this reason, it is often used in the medical sector for the realization of particular prothesis.

Characteristic features of titanium are:

- low specific weight,

- hardness,

- biocompatibility,

- non-toxicity,

- low thermal conductivity,

In addition to be widely used in the medial sector, titanium, thanks to its features, is a metal extremely versatile that can be used in many other sectors, including automotive, aerospace, industrial sector of mechanics and applications in field of sport.

Titanium forging: Mecolpress machines

The temperature for titanium billets forging is about 950°C and the one of the die is about 250°C, instead. The hot forging of titanium parts is very well suited to obtain the desired parts, since by using the right equipment it is possible to avoid all the problems this material should present during the melting.

For this reason, our sales department is at disposal of our customers in order to advice for the choice of the most suitable hydraulic or mechanical press and to suggest the modes of operations. Mecolpress can carry out a simulation test at our factory, thanks to Deform software, and a real forging test so that to grant to our customers that the chosen machine can forge high quality parts.

For further information regarding press models suitable for titanium hot forging, please refer to our sales managers that will be glad to examine in depth the matter.

Metals hot forging process

Metals forging: hot or cold forging?

The forging by means of presses of metals commonly used for the industrial production, such as aluminum and brass, can happen in two ways.

- The first one is the cold coining, carried out, for example, on a piece that already has its own shape and that is forged through the press in such a way to calibrate it and to compact it. The cold coining is suitable, above all, for small size parts and for great production batches, such as screws. The most suitable machines for this type of process are our screw presses.

- The metals hot forging is different from the cold one because it allows to obtain high quality pieces by means of an important deformation of the starting material. With the deformation of brass, copper, aluminum by means of hot forging presses it is possible, indeed, to produce particular shapes, having very complicated structures as well. In order to achieve this forging, Mecolpress proposes, beyond the already mentioned screw presses, also the mechanical and hydraulic presses according to the different production necessities expressed by the customer.

Mechanical and hydraulic presses for the hot forging

The mechanical press can hot forge even complicated pieces. At the end of the process, the forged parts can often have some remaining flash that can be eliminated by means of a trimming machine, machinery that is part of the products range that we offer. The eccentric mechanical press with continuous cycle is recommended for the customers who have high production necessities, while the hydraulic press is more advisable for parts having very complicated shapes and that would require, otherwise, the usage of a lot of material. This type of press permits, indeed, a saving of the input material, so offering to the forger a good margin on the product cost. Moreover, by forging the parts by means of hydraulic hot forging presses, at the end of the productive cycle the parts range that can be produced without flash is much wider, thanks to a progressive and programmable application of the forces. Another characteristic of this type of presses is the flexibility, given by the wide number of available functions.

Hot forging line

For the metals forging a furnace that can be electric (induction) or gas furnace and a press are needed. This is the base productive line for the aluminum, brass, titanium and steel processing; line that can be upstream completed with a sawing machine that cuts the metal bar in billets and with a graphitizing machine, where the billets are treated with the graphite before these are inserted in the furnace, so that these absorb better the heat and that are kept lubricated. The graphitizing, that offers remarkable advantages from a productive point of view, such as a minor gas consumption in the furnace and a superior durability of the dies, is just fitting for some specific production typologies. It is not recommended, for example, for the production of parts that once forged, must be chrome plated or exposed to further particular treatments. Our sales department is at the disposal of our customers for suggesting the best forging line composition according to the product and to application field.

Hot forged metals

The customer’s choice for a specific press for his own productive cycle is based on the material typology used by the forger and on the shapes to achieve.

For the brass forging the hydraulic press is more fitting than the screw press, that is better for the forging of titanium and steel. The eccentric mechanical presses are used for all the metals, even for the copper hot forging. Our sales department is at disposal of our customers for offering the best technical solution for every specific productive situation.

For further information about hot forging machineries, please write us at sales@mecolpress.com