Mechanical press or hydraulic press?

Thanks to the long experience as press manufacturers, Mecolpress can offer to its customers a wide choice of mechanical and hydraulic presses for hot forging and our sales department team can suggest the most suitable machine for the realization of a specific geometry.

Differences between mechanical press and hydraulic press

The mechanic press develops the movements necessary for forging thanks to mechanical connections between the ram and the horizontal coring system of the parts. The upper die close against the lower one and the punches enter laterally. The movements of the mechanical components are therefore all connected with each other and their planning results to be a little bit restricted because if you adjust the movement of a component, you will automatically modify the other ones, as well.

The movements of the components of the hydraulic press are adjusted by hydraulic cylinders instead and you will have an independent control on each axis. This implicates a superior programming flexibility because you can operate on the single components and obtain a better material flow management inside the die.

When it is better to choose a mechanical press

The mechanical at continuous cycle presses for metals hot forging have a higher productivity compared to the hydraulic presses, and this certainly represents an advantage.

There are vertical forged parts, such as the straight junctions or the nuts, that due to their shape are very suitable to be forged by high productivity mechanical presses.

When it is better to choose a hydraulic press

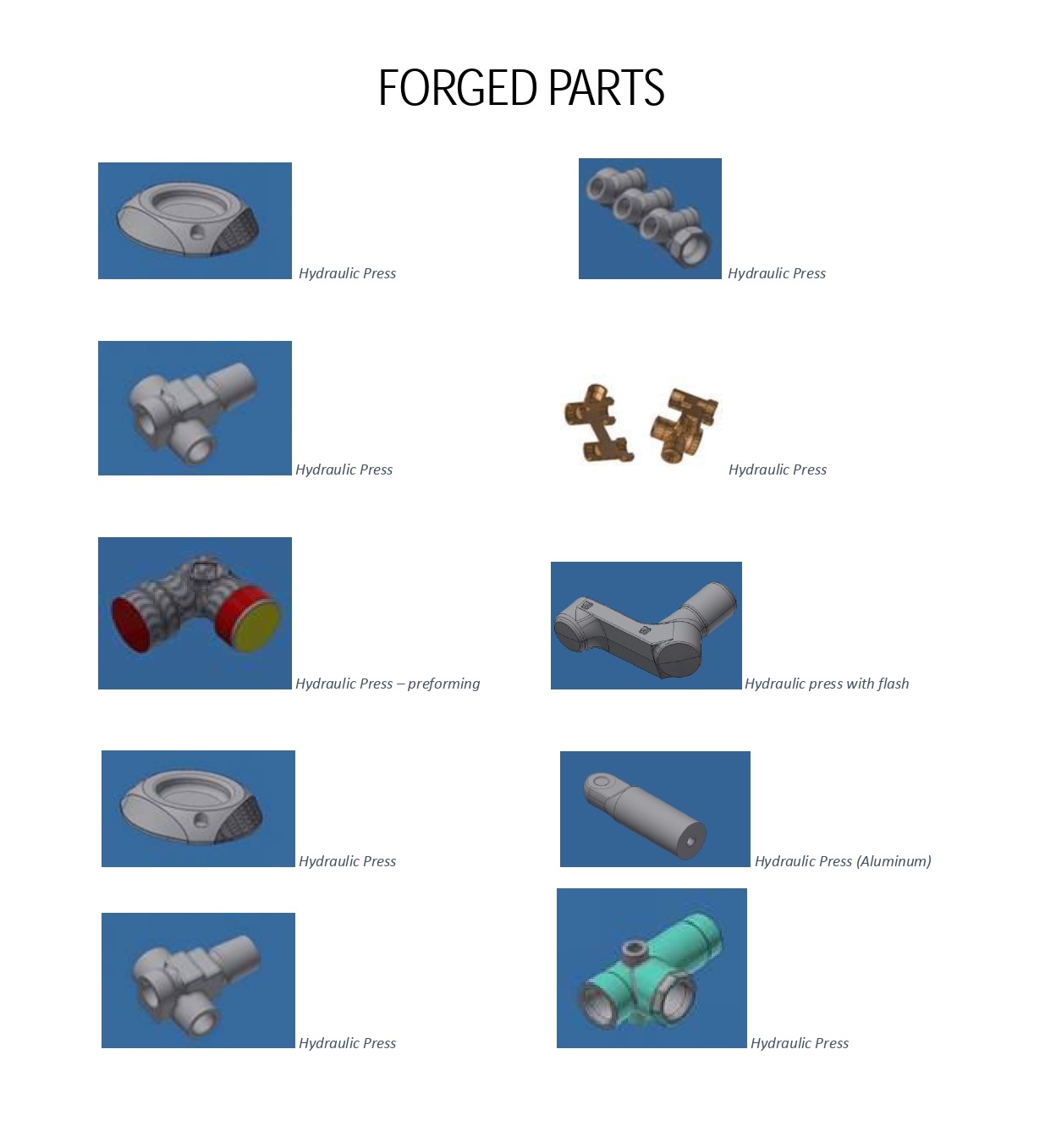

The hydraulic presses allow a major control on the movements of the single components and are more suitable for the realization of parts of complex geometry, such as the slide gate valves. The punches that contribute to the realization of the part are indeed independent and are generally four, placed at 90° of distance from each other, but one or even two punches can be set up with a variable angle of entry, for example of 45° compared to the adjacent one. This implicates a higher flexibility and the possibility to realize some very complex shapes maintaining a high-quality standard.

Another characteristic of hydraulic presses for metals hot forging is the fact that they need less structure inside the productive area because they do not need to be placed on a pit, that is compulsory for the mechanical presses. The positioning of the hydraulic press on simple floor allows a higher flexibility in the factory layout.

The best choice? Ask Mecolpress!

The choice to buy a mechanical or a hydraulic press is almost exclusively made based on the shape of the part to be forged and not based on the material. Both the presses typology forge indeed different types of metals. The only case in which the material can be a decisive factor refers to steel productions that often require the use of a screw press because of the high tonnage.

Mecolpress offers excellent mechanical and hydraulic presses according to the part geometry that the customer wants to realize, and suggests the best and most performing press, that can indeed optimize the production and sparing on the costs.

If you want to receive information regarding our hot forging presses, you can write to: sales@mecolpress.com

Training courses for hot forging

Starting from an inner necessity, Mecolpress has extended the training courses specific for hot forging machineries as a high-quality service against payment that can be offered to its customer companies.

Thanks to the course, it is possible to optimize the production and to improve machines maintenance.

The training value according to Mecolpress

Training is very important, especially in an even more complex productive context and in an even more competitive market. That’s why Mecolpress has felt the need to avail itself of the experience of a hot forging specialist to organize an inner training course of high level.

Understanding the world our customers operate in and learning the art of forging in the best way has always been our priority: therefore, we addressed to Riccardo Segreto that in this interview shared with us very useful suggestions and advanced technical information.

Una volta conclusa questa esperienza molto positiva all’interno della nostra azienda abbiamo quindi deciso di offrire questo servizio di alta formazione anche ai nostri clienti.

Advantages of training courses against payment

Training courses represents a very important instrument for the companies that deal with hot forging, because they offer to people who operate with mechanical and hydraulic presses very concrete and deepened indications regarding how to use them in the best way and to optimize the production.

Today it is not easy to find forging specialists that are available to teach trade secrets. Riccardo Segreto is an independent and very skilled figure, available to share with the companies useful suggestions in order not to wear the press or the die and to improve therefore the productive capacity.

Therefore, a highly qualified staff will be able to carry out some maintenance operations in complete autonomy on machineries for hot forging without the need of Mecolpress customer care service against payment. A correct use of the machine brings therefore to lesser damages and a reduction of machine stops that have a big effect on the production and then on the costs to support.

Our training courses against payment are custom-made developed according to customer’s needs and aimed to the types of presses present in the factory of the company that asked for training. Moreover, they provide an in-depth analysis of the parts to be forged and indications on how to forge them in the best way.

Thanks to our specialist, for example, it is possible to learn how to carry out in the best way the die lubrication and therefore how to prevent its wear and how to adjust the machine stroke. Working correctly with the press has as a result a considerable decrease of costs for our customer companies and that’s why we are firmly convinced that our training courses can represent an added value.

According to companies necessities, the courses can be held at our or customer premises and these have a duration of one or two days, according to the specific program.

Should you need further information regarding training courses, you just have to contact our sales department, sending an e-mail to sales@mecolpress.com.

Courses can be requested both by Mecolpress customer and companies dealing with hot forging that have the necessity to examine in depth some themes.

Optimize the production with Mecolpress training courses

Mecolpress makes available to its customers a training service against payment whose aim is to provide useful information to the staff in charge of the presses in order to use the machines in the best performing way and to optimize the production.

Read this article to discover how training could help a customer of ours to reduce of 50% the maintenance interventions.

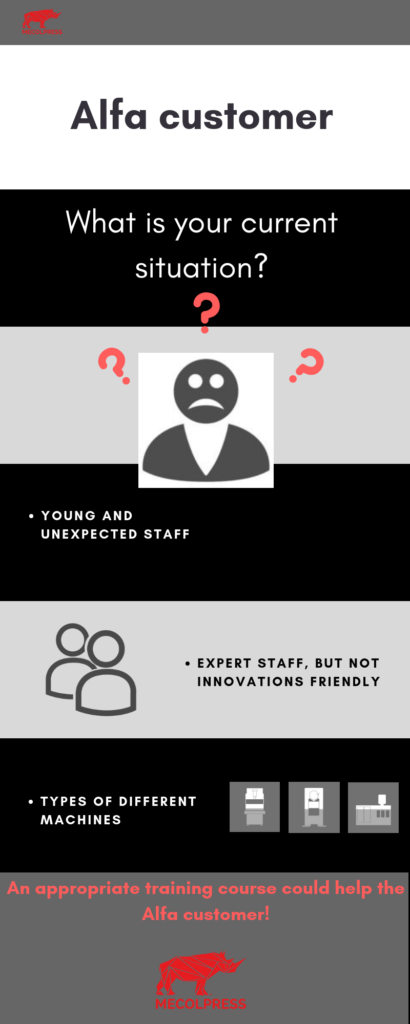

The problems of customer Alfa

Time ago a customer of ours, that we will name Alfa, contacted us because of his interest in custom-made training courses for forging machines proposed by Mecolpress. The reasons why he decided to activate the course were several.

First of all, the company employees were not adequately trained and could not use the forging machines in the best way. This implicated a frequent request of assistance from Mecolpress by the customer, and even if our intervention was very prompt, the company had to face up to the interruption of the productive process and to the additional costs connected to the customer care service.

In addition, the company hired new young but still not-expert personnel, however definitely open to technologic innovations and able to use the informatic devices of production machineries.

By their side there was also experienced personnel, working in the company for many years, with greater familiarity with forging techniques, but with some difficulties to approach their selves to the new digital techniques. Persuading them to change method was not so easy, because the long experience matured during years with their procedures.

In closing, the Alfa customer has at his disposal a various set of machines including dated presses, trimming presses, mechanical presses and a new hydraulic press, just bought.

For all these reasons, our customer has felt the need to take advantage of a new custom-made training course that can teach to the operators how to use the machines in the most performing way and to obtain the maximum output with minimum effort.

Mecolpress training course

According to the needs expressed by our customers we have planned a custom-made training course that takes account of forging machines in the company and of the type of forged parts.

The course is structured as follows:

- Introduction to hot forging;

- Explanation of drawings and simulation program in support of parts to be forged;

- Parts forging in the factory with an entirely devoted machine;

- Answers to questions of the personnel, detailed studies and explanations on problems regarding the production.

In particular, during the course very relevant matters were debated, such as die and process preliminary analysis, setting of specific parameters, driven setting of the hydraulic presses for parts with flash and without flash and analysis of output with simulations.

Result of the course

Our customer was particularly satisfied with our custom-made training course because of the obtained result.

Indeed, the personnel could acquire an increased competence regarding hot forging, both generally and specific, related to the company production type.

Moreover, the course has contributed to reinforce the team spirit among employees, that is of high importance to create a working environment based on collaboration. Indeed, activities of this kind contribute the personnel to interact more, to better work as a team and also to better face with the daily difficulties.

After our training our customer has decreased drastically the number of service requests against payment. Indeed, the operators in charge of machines can now use better the presses with a lesser wear and they can carry out in autonomy some activities of ordinary maintenance, without the need of Mecolpress technicians.

For further information about Mecolpress training courses, please send an e-mail to: sales@mecolpress.com.

Metals hot forging process

Metals forging: hot or cold forging?

The forging by means of presses of metals commonly used for the industrial production, such as aluminum and brass, can happen in two ways.

- The first one is the cold coining, carried out, for example, on a piece that already has its own shape and that is forged through the press in such a way to calibrate it and to compact it. The cold coining is suitable, above all, for small size parts and for great production batches, such as screws. The most suitable machines for this type of process are our screw presses.

- The metals hot forging is different from the cold one because it allows to obtain high quality pieces by means of an important deformation of the starting material. With the deformation of brass, copper, aluminum by means of hot forging presses it is possible, indeed, to produce particular shapes, having very complicated structures as well. In order to achieve this forging, Mecolpress proposes, beyond the already mentioned screw presses, also the mechanical and hydraulic presses according to the different production necessities expressed by the customer.

Mechanical and hydraulic presses for the hot forging

The mechanical press can hot forge even complicated pieces. At the end of the process, the forged parts can often have some remaining flash that can be eliminated by means of a trimming machine, machinery that is part of the products range that we offer. The eccentric mechanical press with continuous cycle is recommended for the customers who have high production necessities, while the hydraulic press is more advisable for parts having very complicated shapes and that would require, otherwise, the usage of a lot of material. This type of press permits, indeed, a saving of the input material, so offering to the forger a good margin on the product cost. Moreover, by forging the parts by means of hydraulic hot forging presses, at the end of the productive cycle the parts range that can be produced without flash is much wider, thanks to a progressive and programmable application of the forces. Another characteristic of this type of presses is the flexibility, given by the wide number of available functions.

Hot forging line

For the metals forging a furnace that can be electric (induction) or gas furnace and a press are needed. This is the base productive line for the aluminum, brass, titanium and steel processing; line that can be upstream completed with a sawing machine that cuts the metal bar in billets and with a graphitizing machine, where the billets are treated with the graphite before these are inserted in the furnace, so that these absorb better the heat and that are kept lubricated. The graphitizing, that offers remarkable advantages from a productive point of view, such as a minor gas consumption in the furnace and a superior durability of the dies, is just fitting for some specific production typologies. It is not recommended, for example, for the production of parts that once forged, must be chrome plated or exposed to further particular treatments. Our sales department is at the disposal of our customers for suggesting the best forging line composition according to the product and to application field.

Hot forged metals

The customer’s choice for a specific press for his own productive cycle is based on the material typology used by the forger and on the shapes to achieve.

For the brass forging the hydraulic press is more fitting than the screw press, that is better for the forging of titanium and steel. The eccentric mechanical presses are used for all the metals, even for the copper hot forging. Our sales department is at disposal of our customers for offering the best technical solution for every specific productive situation.

For further information about hot forging machineries, please write us at sales@mecolpress.com

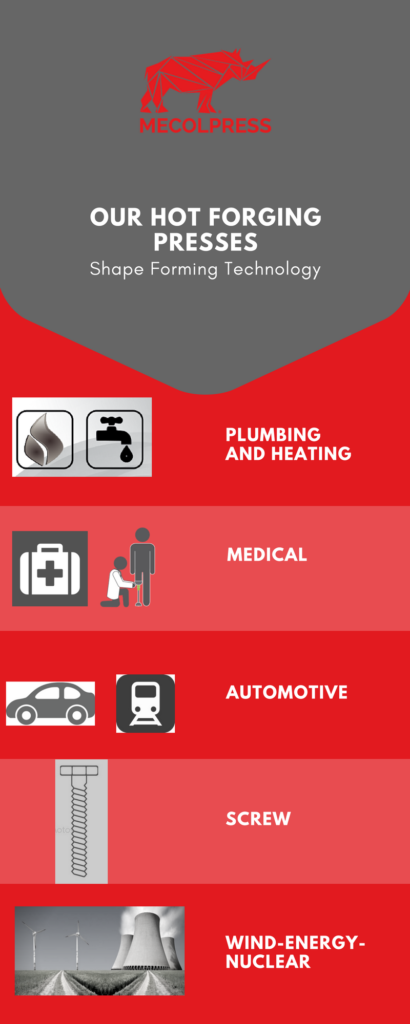

Hot forging presses: Mecolpress technology

Application sectors of the hot forging

Mecolpress offers a wide range of hot forging presses, able to satisfy the necessities of the individual customers and that allow to forge parts for different industrial sectors. Our presses can be used for the production of:

- Thermohydraulic pieces;

- Mechanical parts in aluminum, copper and brass, used in the railway and automotive sector;

- Clothing parts such as buckles and zippers;

- Stainless, titanium and steel screws for applications in any sectors, from the aeronautics to the railway.

The bio-medical one represents a very particular sector, indeed, with our presses it is possible to forge parts for titanium prothesis. The pieces produced by Mecolpress machines address also to the sector of the production and distribution of high-pressure gas, for the medical, automotive and industrial sector.

Not only mechanical presses, here the Mecolpress proposals

A functional commitment that all these sectors have in common undoubtedly is the precision during the material forging, but also from a design point of view Mecolpress reaches through the research for the perfect shapes a remarkable significance. This is exactly why we propose different typologies of presses, including hydraulic presses, mechanical presses, clutch and electrical servomotor screw press, knuckle joint press and trimming machine, that are able to hot forge several materials, including brass, steel, aluminum, titanium and copper.

The support of our Research & Development department

Our range of presses, so differentiated, is due to the work of our Research and Development department, a team that has revealed itself as very precious, not only for Mecolpress Company but also for our customers, because it allows them to achieve several goals. First of all, our staff helps the forger to identify the systems to optimize the production through hot forging of parts in such a way that the further machining will not be needed. Moreover, our specialists can evaluate what could be the productive implications in the usage of different metals alloys and help to identify them. The Research & Development department offers support also for adapting the complete hot forging line composition according to the customer’s needs, to his industrial sector and to the habits of the specific Country.

So, our company is at disposal of the customers in such a way to define with them the hot forging processes, in order to achieve the best result in the production also of high tech parts.

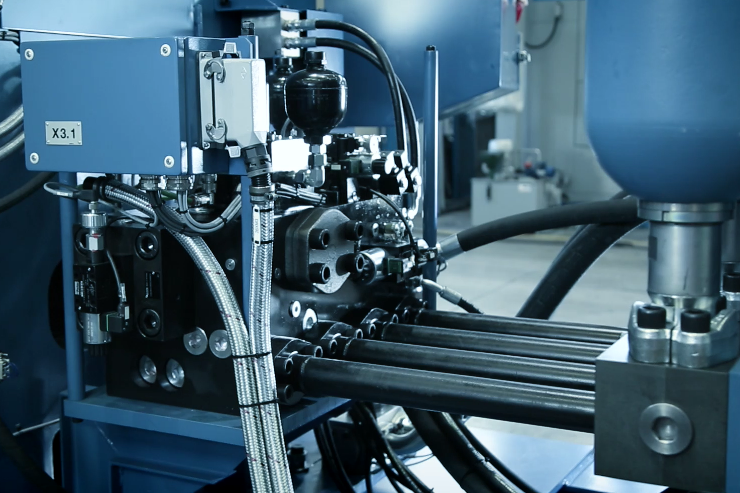

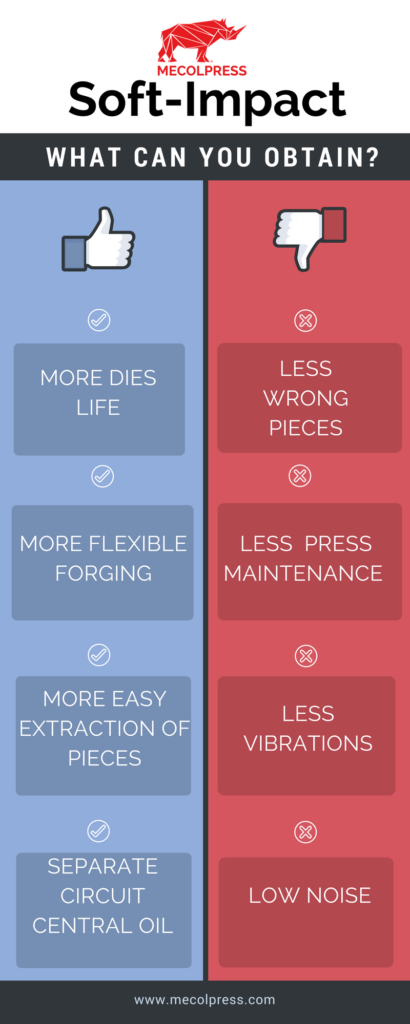

Soft-Impact hydraulic cushion for eccentric mechanical presses

A recent innovation by Mecolpress for eccentric mechanical presses.

Mecolpress proposes to equip the eccentric mechanical presses of an innovative hydraulic cushion, Soft-Impact.

Features:

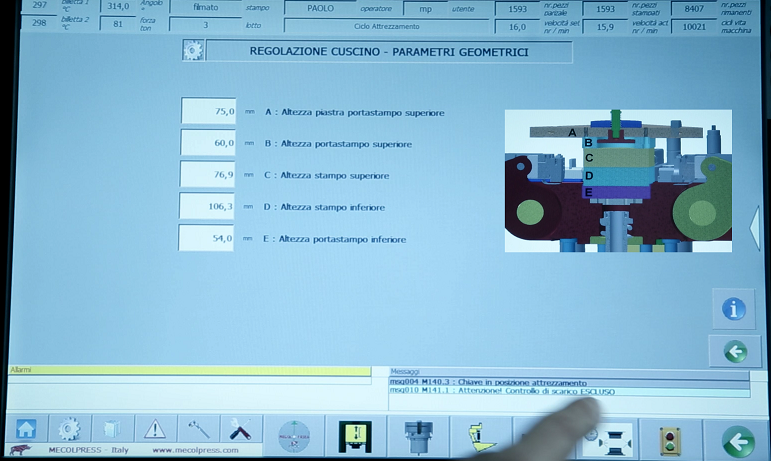

- It is a real hydraulic cylinder with a stroke sensor on the shaft;

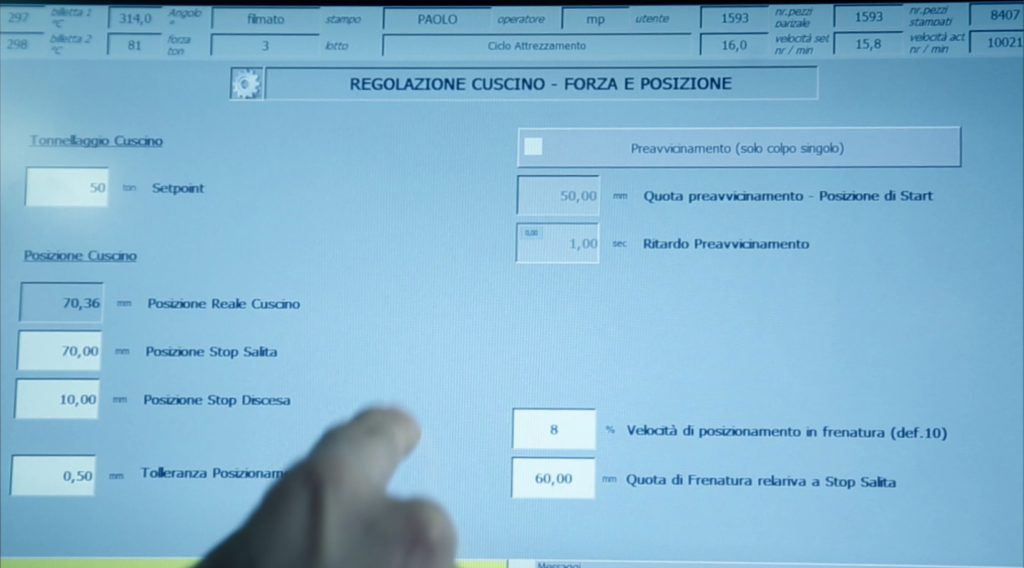

- Movements are fully programmable and controlled by means of proportional valves;

- Starts independently the down-stroke and then the punches move forward toward the die center before the upper die hits the lower one;

- Strokes adjustment from operator panel by simply inserting the desired dimensions and the data of die and die-holder heights;

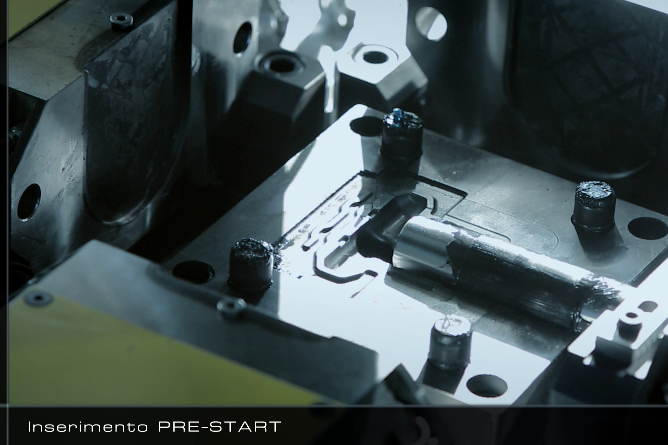

- As alternative, the function “punches pre-start” allows the punches to move close to the billet before the die closes and the forging begins.

- Dedicated hydraulic unit, separated from the machine clutch one.

Thanks to the here above-mentioned features, the soft-impact hydraulic cushion allows the mechanic eccentric presses to achieve important results:

- Extremely simplified mechanical components;

- Precise adjustment from the operator panel of the start, stop and braking quota; all set parameters are saved together with the piece recipe;

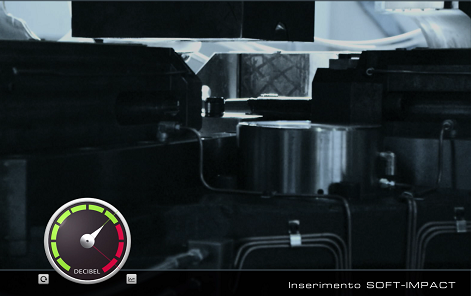

- The upper die does not crash violently against the lower one, because it “reaches” the second one while it is already in the descending phase;

- The control system automatically calculates the speed and the moment to start the cushion;

- When the material deformation begins, the punches are already in an advanced position decided by the operator (it can be saved in the piece recipe); when the die re-opens, the punches then go back beyond the quota of work start;

- Separate blocks modular system.

Benefits:

- Less and simpler maintenance;

- Ease of use, machine set-up and perfect repeatability of forging’s cycles;

- Reduction of vibrations, resulting in general benefits for the press and for the working environment;

- Reduction of noise;

- Increased working life of dies and pins;

- No complicated calculations or measures for the operator;

- Possibility of reduction of forging defects due to material that goes out along the empty punch channels and then is pushed inside by punches starting their stroke too distant;

- Ease ejection of pieces (having an extra back stroke) without penalizing the cycle time;

- The oil in the cushion control unit has its own independent circuit and does not mix with the clutch oil, usually dirtier.